Mechanical

Bilfinger supports the energy and process industry by delivering comprehensive mechanical solutions in the following specialist areas:

- Process and detail engineering (mechanical)

- Production and installation of vessels, tanks and equipment

- Piping construction

- Steel structures

- Plant installation

- Rotating equipment

- Fittings service

- Quality assurance and quality control

With our in-house workshops, we provide our customers with customized solutions, guaranteeing the highest level of quality and safety. Our team of highly competent mechanical professionals ensure that the power and process industries are able to increase plant efficiency.

Process and Detail Engineering (mechanical)

Bilfinger has a strict focus on its customers and offers innovative engineering solutions in all areas of process plant engineering.

We offer the following services:

- Pre-engineering

- Basic and detailed design

- Consulting

- Monitoring

- Project management

We work with the most modern design and calculation programs and have our finger on the pulse of the most recent developments in the industry.

Production and Services for

Vessels, Tanks and Equipment

Bilfinger looks back on decades of experience in the manufacturing field. Flexible, reliable and clearly focused on the customer, we are a competent and efficient partner in international plant engineering. With our extensively equipped workshops and flexible working hours, we can ensure our customers receive customized products of the highest quality.

Prefabrication includes the manufacture of piping spools and assemblies for complete industrial and power plants throughout the world.

We produce smaller tanks, steel constructions, and a wide range of custom components with full control over quality, delivery, and production time. Our workshops are equipped with dedicated halls for stainless steel and carbon steel fabrication, effectively preventing cross-contamination and ensuring consistently high standards.

By manufacturing components in a controlled environment, we enable faster and safer installation on-site, reduce construction time, and increase cost-efficiency. Our prefabrication capabilities offering flexible solutions tailored to each customer’s needs.

We offer our customers a comprehensive service package along the entire value chain from design and production to maintenance & repair for tanks, boilers, vessels, heat accumulators and related equipment, such as filter separators, heat exchangers, process vessels, burners, scrapper traps, storage vessels and general pressure vessels. Being your equipment partner we ensure smooth operation, increased efficiency and reliability of your static equipment.

- Boilers

Bilfinger offers comprehensive services for industrial boilers and e-boilers, including inspection, overhaul, repair, and upgrades. As boiler OEM, we provide various types of boilers, such as conventional, electric and hybrid boilers. We are also your implementation partner for Zeta E-boilers in the Netherlands, Belgium and the UK.

With more than 155 years of experience, Bilfinger ensures reliable steam production with minimal environmental impact regarding CO2 emissions and fossil energy use. We also offer innovative technologies like hydrogen steam boilers and pyrolysis boilers and are your supplier for high-quality boiler equipment, boiler parts and spare parts.

- Deaerators

Deaerators are crucial in preventing corrosion in boiler systems by removing oxygen from the feedwater. Bilfinger offers advanced, patented spray-type deaerators that are more sustainable and cost-effective. They require no oxygen-absorbing chemicals and reduce steam loss by 90%.

Retrofitting existing tray-type deaerators with Bilfinger's spray-type components can significantly enhance performance, lower environmental impact, and reduce noise levels. Thanks to improved efficiency and extended equipment life, this retrofit typically yields a payback period of less than three years.

- Steam accumulators

Steam accumulators are crucial for managing steam demand and production fluctuations and serve as a strategic steam reserve. They help to lower your CO2 footprint and reduce fossil fuel consumption.

As OEM our standard steam accumulators can be manufactured up to 32 meters in length and 4.8 meters in diameter, storing up to 10-15 tons of steam per charge. Larger sizes and capacities are also available upon request. The response times for steam accumulators are typically about 2 seconds for initial response and 20 seconds for full flow during charging or discharging.

- Burners

Burners are essential in modern energy production, designed to minimize harmful emissions, enhance reliability, and allow flexible fuel use. Designing and implementing combustion technology often requires tailored solutions. At Bilfinger, we leverage over 100 years of experience in burner and boiler production. Our team of experts is ready to develop the optimal combustion solution to meet your specific needs. This includes converting existing boilers from liquid fuel to natural gas or hydrogen, and installing burners capable of handling multiple fuel streams

Bilfinger has decades of experience in the field of welding. Our team of welding technology specialists works with the following welding methods:

- Manual arc welding

- Metal active gas/metal inert gas welding

- Tungsten inert gas welding

- Gas fusion welding

We ensure compliance with both national and international standards and regulations.

We offer tailored maintenance and repair solutions for tanks, vessels, and process systems - always adapted to your operational needs and industry requirements.

With decades of experience in tank projects across sectors of the process industry, Bilfinger is your reliable partner throughout the full lifecycle of your installation. Our services range from minor repairs and component replacements to full-scale refurbishments, always with a strong focus on safety, quality, and long-term performance.

By combining our extensive industry knowledge with high-precision welding expertise and flexible project execution, we ensure minimal downtime and optimal function. Whether scheduled maintenance or emergency repair, we deliver proven reliability and technical excellence you can depend on.

Piping Construction

We offer top-quality individual piping solutions and always in accordance with the highest technological standards. Through the extensive prefabrication of piping and components in our own workshops, Bilfinger ensures efficient workflows and a high level of safety and quality.

We manufacture and assemble high-quality piping systems in all common nominal sizes and made from a range of materials:

- Stainless steel

- Hastelloy

- Steel / PTFE

- Enamel

- Plastic

- PVDF

- Glass

Steel Structures

We produce steel and specialized structures of any kind, including stages, platforms, stairs, walkways, pipe bridges, piping supports or the manufacturing of skids. Bilfinger is the partner you need when it comes to aluminum and steel structures. We support our customers not only in design, but also in the preparation of structural analysis (including drawings) and parts lists as well as in the modular planning of skids and piping bridges.

Our manufacturing and approval processes are based on DIN EN 1090-2 with design classes EXC 3 and EXC 4.

Plant Installation

The professional installation of plants, equipment, machines and systems is a decisive factor in the industry. With our experts, we work to ensure smooth commissioning and trouble-free operation of your plant.

We are specialized in the creation of what are known as Mechanical Execution Concepts which enable us to apply our many years of expertise in a time and cost-efficient manner for our customers at an early planning stage.

We have decades of experience in various industries, including the chemical and pharmaceutical industry, power plant and mechanical engineering as well as in the new industries associated with the energy transition, such as battery production, hydrogen and CCUS.

Customized Solutions in Plant Engineering

Our mechanical services go beyond mere pipeline construction. We develop customized solutions for our customers that optimally meet their needs. Whether it's heat storage or pumps, hydropower, or gas drying systems, we have the expertise and equipment to fabricate tanks and pipelines to measure.

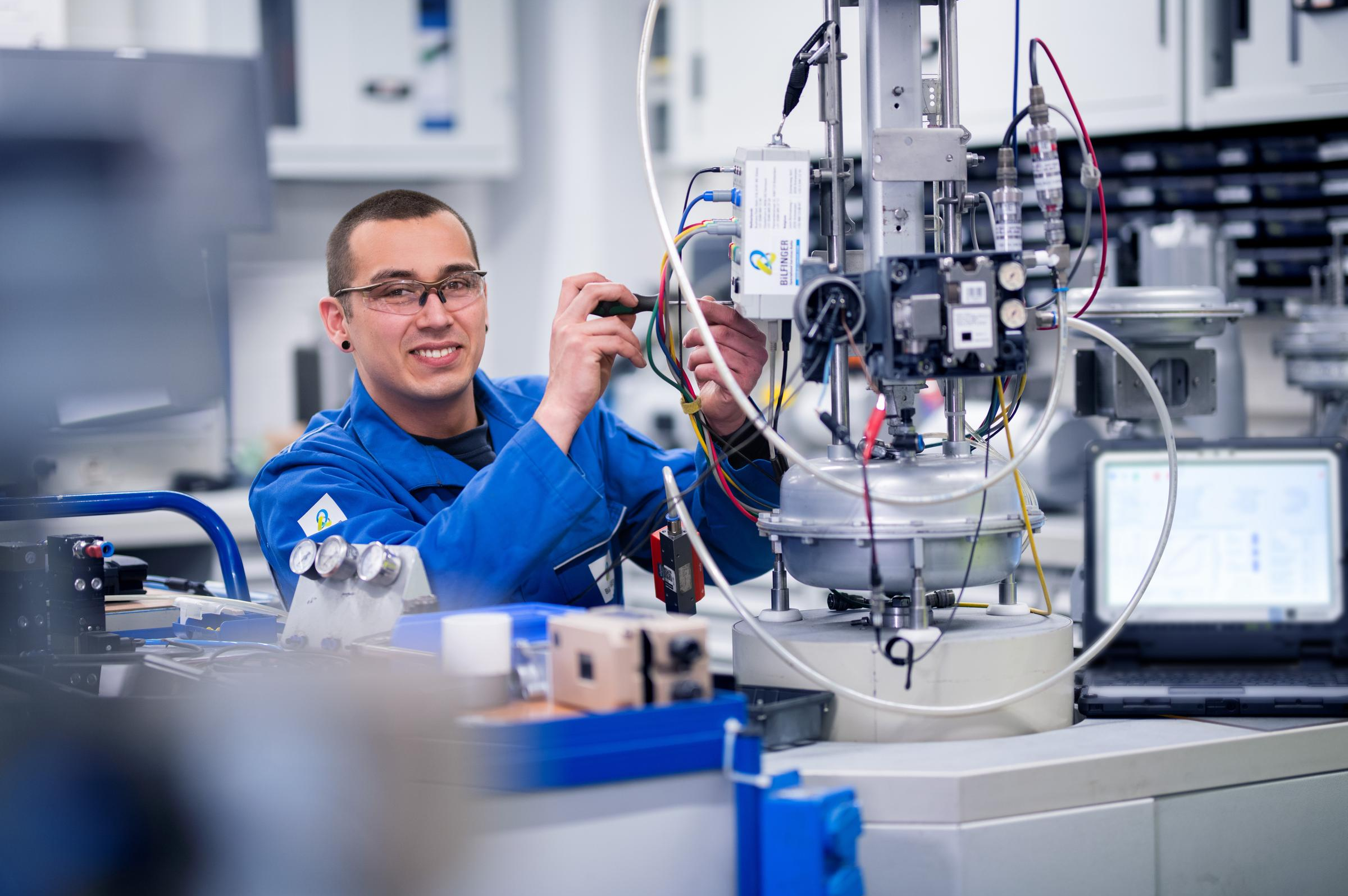

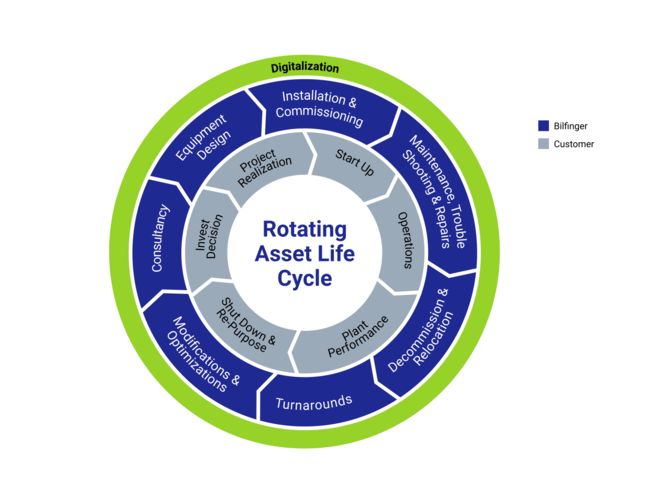

Services for Rotating Equipment

From manufacturer-independent consulting and maintenance to ongoing optimization and repair, Bilfinger offers comprehensive services throughout the entire service life of rotating equipment. We monitor ongoing operations and guarantee process safety and maximum reliability. This service package is complemented by a large rental pool that includes 20,000 pieces of equipment consisting of pumps, drive motors and frequency converters.

High availability, time efficiency, cost savings

Pumps, reciprocating compressors and turbomachinery are at the heart of many production plants. They convey liquid or gaseous raw materials as well as process industry end products and ensure they are in constant motion. Because they generally operate around the clock, they are significantly responsible for the availability and economic efficiency of process industry plants.

Bilfinger employs a large number of highly skilled workers with a variety of key qualifications, Including supervisors, project managers, planners, machine and turbine fitters.

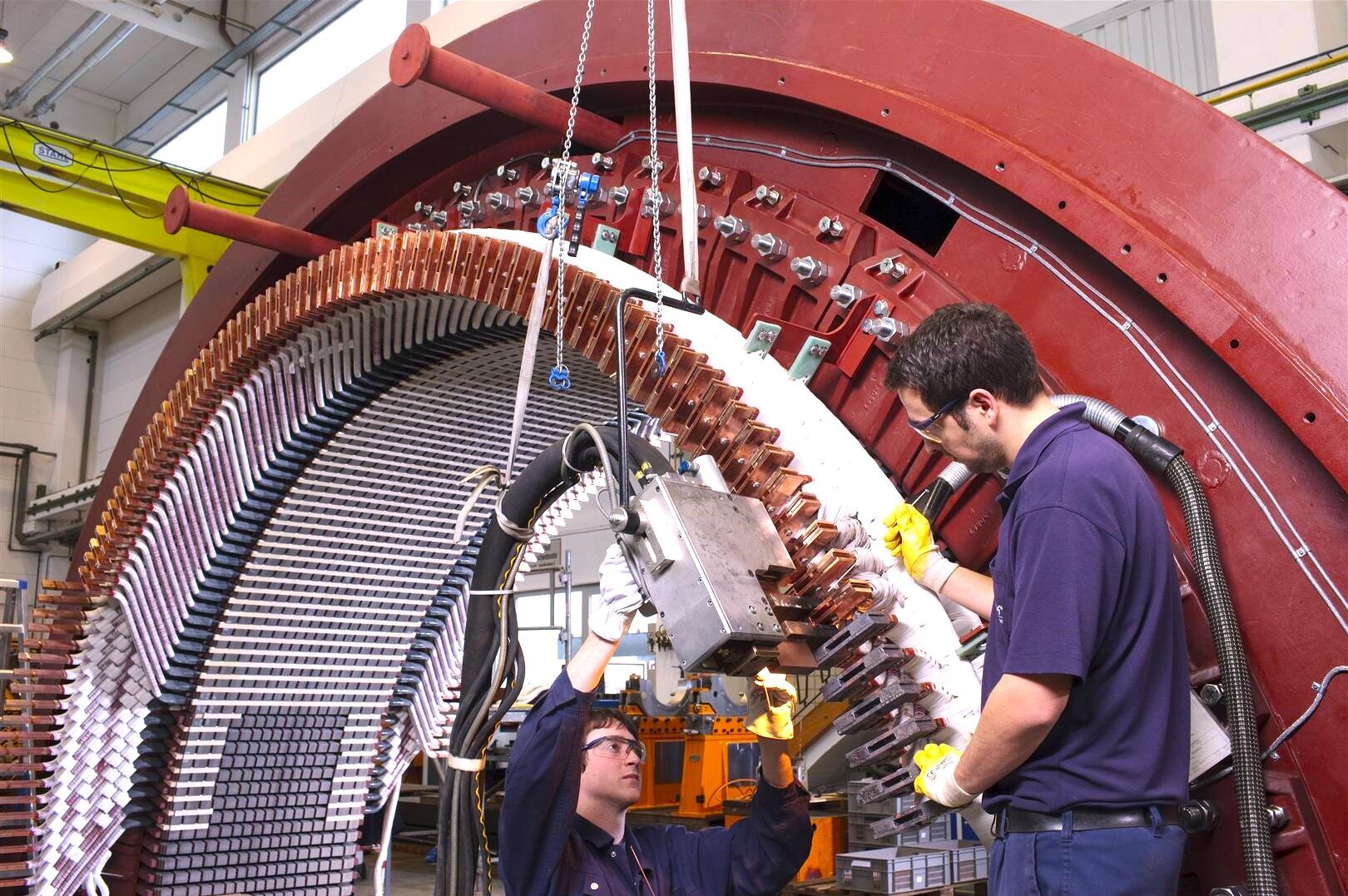

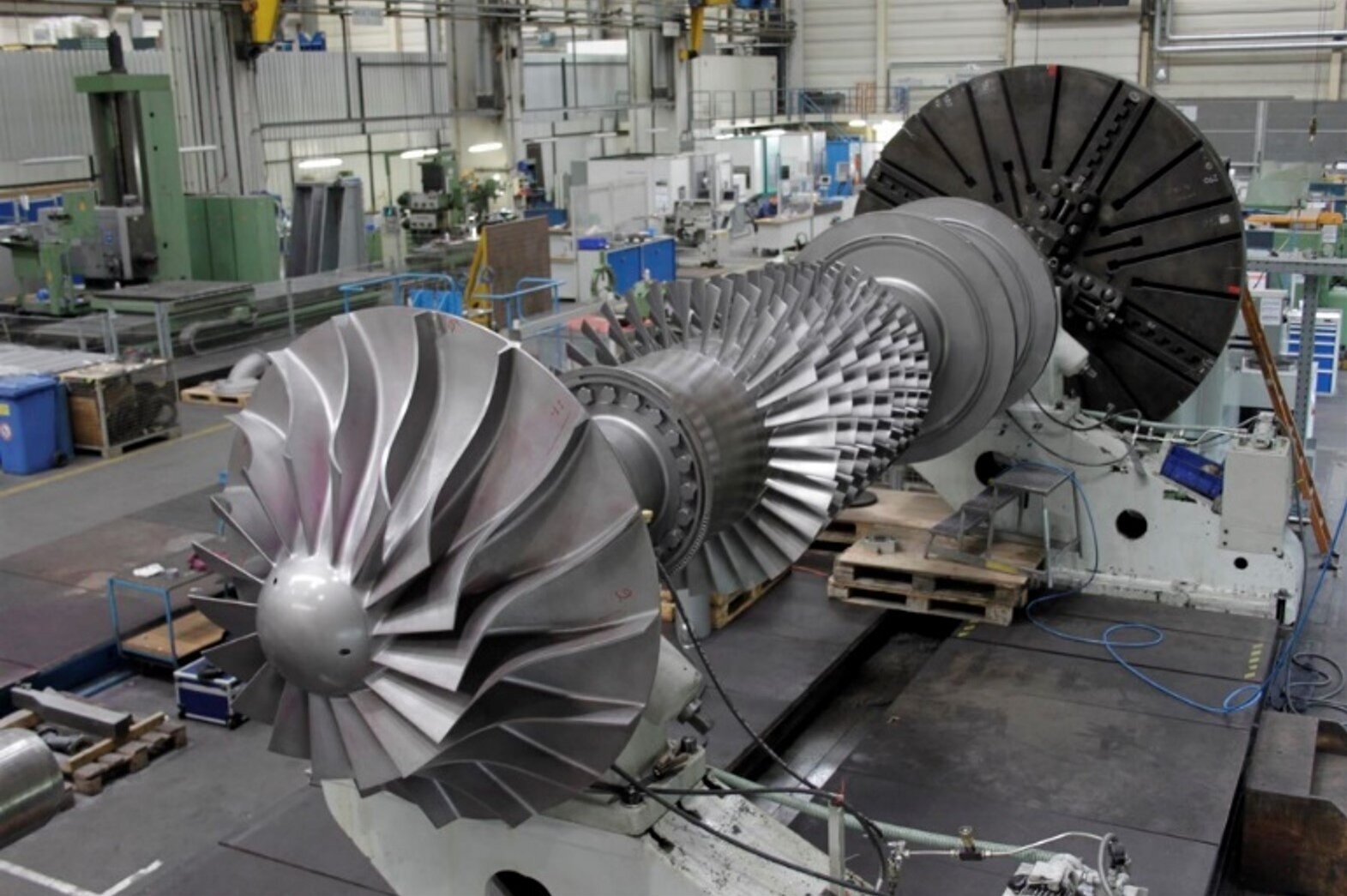

Bilfinger offers comprehensive workshop services for heavy rotating equipment such as engines, turbines and compressors. The services include disassembly, testing, overhaul, replacement, heat treatment, balancing, reverse engineering, reassembly and alignment of the machines. These services ensure the high quality, safety and reliability of the machines.

- Consulting:

Experienced technicians and engineers support customers as early as the planning phase and work to optimize availability as well as improve the energy efficiency of rotating machines - Maintenance:

Predictive maintenance using vibration measurements to avoid unexpected downtime and reduce repair costs - Workshop service:

OEM-independent full service with detailed damage analysis and solution-oriented repair - Rental equipment pool:

Reducing customers’ investment costs by renting pumps, electric motors or frequency converters; uncomplicated and fast replacement supply in case of damage of the rented equipment

- Turbines

Optimize your steam turbine with our comprehensive lifecycle services that include inspection, maintenance, repair, and overhaul (MRO). Our integrated services ensure maximum performance and longevity of your equipment, reducing downtime and operational costs.

Periodic inspections and condition monitoring keep your turbines in top condition, while our expertise with multiple OEMs guarantees high-quality maintenance. We offer tailored solutions for performance enhancement and efficiency improvements to meet your evolving business needs. Thanks to our in-depth knowledge of gearboxes, generators, compressors, valves, pumps and e-motors, we provide integrated services that cover the entire drivetrain.

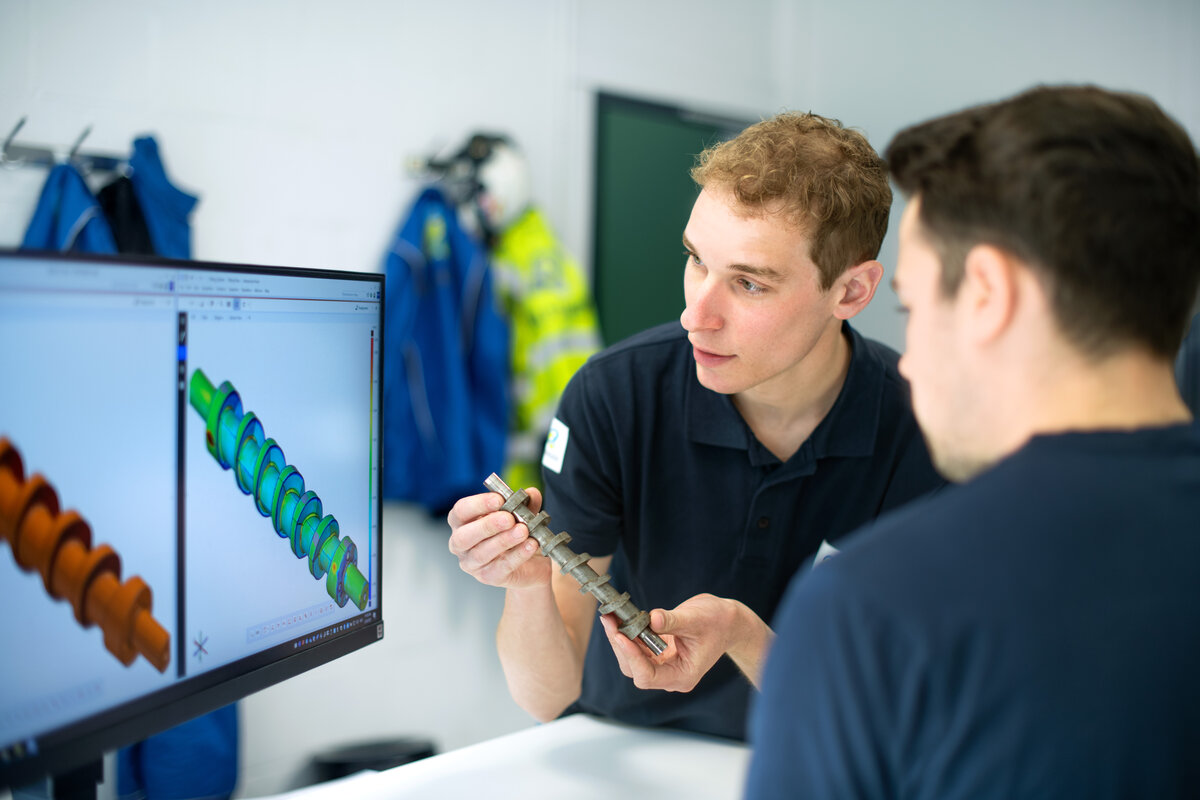

- Compressors

Compressors are vital for many industrial processes, ensuring optimal operation of your facilities. At Bilfinger, we understand their importance and offer comprehensive solutions to maintain peak performance.

Regular maintenance and timely repairs are crucial to prevent failures and unplanned downtime. Our services include inspections, diagnostics, full overhauls, and minor repairs. We also help our industrial clients with compressor master controllers upgrades for better performance and improved energy efficiency.

Whether it’s air, gas, turbo, or steam compressors, our experts are ready to inspect, repair, and upgrade your equipment. Extend the lifespan and improve the efficiency of your compressors with our professional services.

In the Netherlands, we are also your partner for the procurement and installation of Hanwha power systems’ centrifugal compressors and Elgi screw compressors.

- Gearboxes

Gearboxes are crucial components in various industrial and maritime applications, ensuring the smooth transfer of extreme forces. Bilfinger, an OEM for brands like Jahnel-Kestermann and Rademakers, offers high-quality gearboxes and comprehensive services including design, inspection, repair, and maintenance. We also provide fast production of spare parts using advanced 3D scanning and CNC machining. Specializing in industrial and marine gearboxes, Bilfinger ensures reliability and efficiency for business operations and maritime propulsion systems globally.

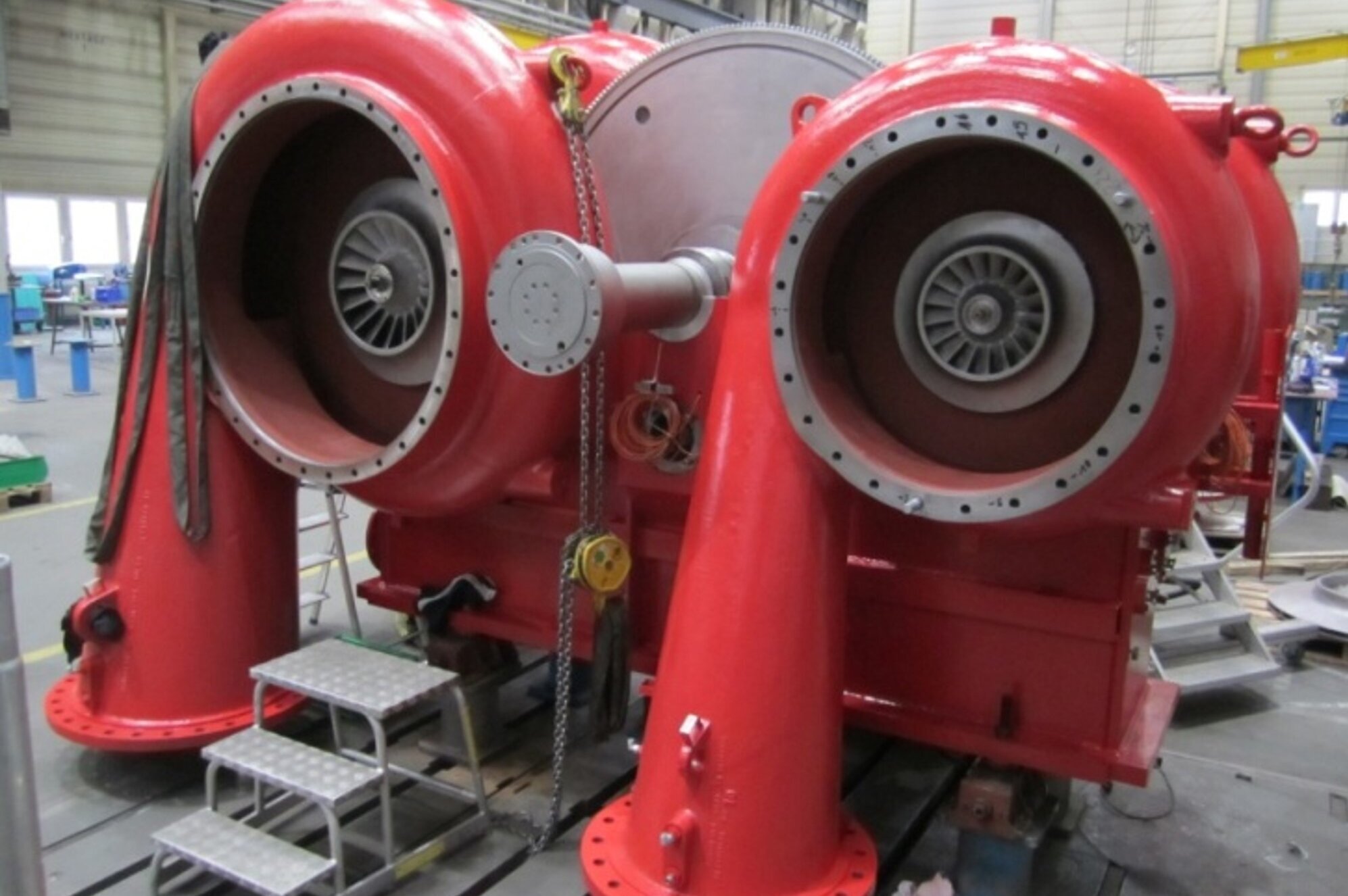

- Pumps

We are a global leader in engineered pump solutions for large-flow applications like flood control, drainage, and cooling water supply. With over 150 years of experience, we design custom-built pumps that handle high water volumes efficiently and reliably.

Our pumps protect infrastructure, manage water levels in urban and agricultural areas, and regulate temperatures in industrial operations. Each system is engineered for durability, energy efficiency, and minimal environmental impact, including fish-friendly technology.

We offer comprehensive services from new builds to maintenance, ensuring long-term performance. Our pumps are known for precision, durability, and reduced operational costs, with a focus on sustainability and innovation.

We supply critical spare parts for rotating equipment with short delivery times and guaranteed quality to minimize downtime. Exceeding the OEM standards and lead times, we support the fulfillment of service expectations, manufacture spare parts, perform 3D scans and re-engineering.

Our turbo blading experts provide high-quality blades, rotors, and other essential components for turbomachinery, ensuring reliability and efficiency. These can be steam- and gas turbine blades, vanes, disks, impellers, stators/diaphragms, and nozzles up to complete rotors. We offer solutions for all OEMs, including reverse engineering for obsolete parts. Our products, designed to the highest standards, include advanced techniques for protection and optimization, such as stellite, laser cladding, and CFD/FEM analysis.

Valve Service

Our qualified specialists carry out manufacturer-independent services on valves and plant components of all sizes in close coordination with the responsible inspection authority. We would be happy to provide you with advice regarding plant shutdowns.

- Maintenance:

Repair of all makes and nominal sizes in our workshops as well as on site in your plants - Workshop service:

OEM-independent complete services with detailed damage analysis and repair in accordance with the manufacturer’s specifications, full documentation including acceptance by the responsible inspection authority - Manufacturing of spare parts:

OEM-independent procurement and in-house production of spare parts in accordance with drawings or state-of-the-art 3D measurement; uncomplicated and fast supply of critical spare parts in the event of damage

Quality Assurance and Quality Control

Bilfinger conducts it services in accordance with international regulations and approves them. We rely on strict quality assurance (QA) and quality control (QC) throughout the production process. This ensures the achievement of the desired product quality.

Bolting & Tensioning

Effective flange management and bolt integrity are critical to safe and leak-free equipment production. Our experienced team uses various tools and techniques to secure bolted joints and offers comprehensive solutions for tightening and tensioning projects.

Bolting & Tensioning Services

- Torquing & tensioning

- Load measuring

- Hot bolt clamping

- Flange protection

Machining

Our machining technology is equipped with modern turning, milling and grinding machines as well as boring machines and covers a wide range of machining tasks.

Heat treatment

We support with comprehensive heat treatment services, including weld integrity control through preheating, post-weld heat treatment and metal property enhancement.

Plastics & GRP Composites Engineering

Bilfinger offers efficient, competitive and comprehensive engineering services for plastics and Glass Reinforced Plastic (GRP) for customers in the process industry. With extensive experience in the use of non-metallic systems for storing and moving fluids from water to highly hazardous industrial chemicals, our skilled in-house engineers and designers are able to design, supply and install the most appropriate option for every asset.

All aspects of the order from design to installation and testing. An integrated and coordinated approach that saves both time and money for the customer.

Design and fabrication to meet even the most demanding specifications.

Fast and efficient on-site services with minimal disruption to customer's operations.

Installation and testing for a wide range of pipelines including water mains, gas mains, hydrant and sprinkler mains, and pre-insulated mains.

Inspections to spot problems before serious structural damage occurs. With even plastics subject over time to both reductions in chemical resistance and external corrosion, regular inspection is vital for both operational efficiency and safety.

A reliable maintenance and repair service from our skilled in-house engineers and technicians. Services are provided for both ad hoc projects and as part of term maintenance contracts.

Using the latest technologies, we supply a comprehensive and fully certified range of services ranging from GRP composites and thermoplastic fabrications through to fluoropolymer-lined steel tanks and pipework for equipment in hazardous environments both on- and offshore. Working on pipes, ducting, tanks and vessels, we also provide inspection, repairs and maintenance to keep equipment functioning efficiently and prevent any risk to either personnel or operations.

Modern non-metallics such as Glass Reinforced Plastic (GRP), Glass Reinforced Epoxy (GRE), Polyvinyl Chloride (PVC), High Density and Medium Density Polyethylene (HDPE/MDPE) and Polypropylene (PP), typically offer better lifetime value than conventional metal alternatives - but only if the right material is selected for the specific operational requirements.

Our engineers identify what will work best for our customer's unique requirements, considering the vast range of possible combinations and permutations of materials capable of addressing a multitude of different scenarios. In addition, they provide the careful design and specification that is crucial to success when working with anisotropic materials. As a result, customers receive a tailor-made system that provides the optimum balance of performance, strength, and durability giving the best possible return on your investment.

Benefits for Our Customers

- Plant construction from a single source, from engineering to implementation and commissioning

- Avoiding unnecessary interfaces and costs

- Increased asset availability through status-based maintenance and optimization measures

- Short-term and flexible access to a large number of specialist tools and human resources with a range of qualifications

- Cost-efficient and sustainable service solutions throughout the entire service life of the rotating machine

- Sustainable repair by machining the parts on site in your plants as well as overhauling plant components if technically possible and necessary

Where Our Mechanical Services Have Made a Difference

Global Product Manager Mechanical

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/8/csm_Header_Reference_BPLingen_219b6c2cd4.png)

![[Translate to English:] [Translate to English:] Project ISOPAR](/fileadmin/UK/BILFINGER-FAWLEY2456.MXF.10_04_24_01.Still001.jpg)

![[Translate to English:] [Translate to English:] Fast Track Pipework](/fileadmin/UK/IMG_8058.jpg)

![[Translate to English:] [Translate to English:] Flare Replacement](/fileadmin/UK/Bilfinger_9.jpg)

![[Translate to English:] [Translate to English:] Heat Exchanger Replacement](/fileadmin/UK/Recruitment_2.jpg)