- Development of sustainable storage solutions for green hydrogen on a commercial scale

- EPCm contract for Bilfinger follows convincing engineering performance

- Bilfinger's demonstration plant “H2DRY” enables efficient, large-scale hydrogen treatment

Krummhörn, Germany. Bilfinger has been commissioned by energy company Uniper to provide engineering, procurement and construction management (EPCm) services for a pioneering hydrogen project in the Krummhörn cavern storage facility in Lower Saxony, Northern Germany. The aim of this research project is to develop a commercial storage solution for green hydrogen on a large scale. Uniper's storage facility will be one of the first of its kind and is the second research project to use the hydrogen processing technology “H2DRY” developed by Bilfinger.

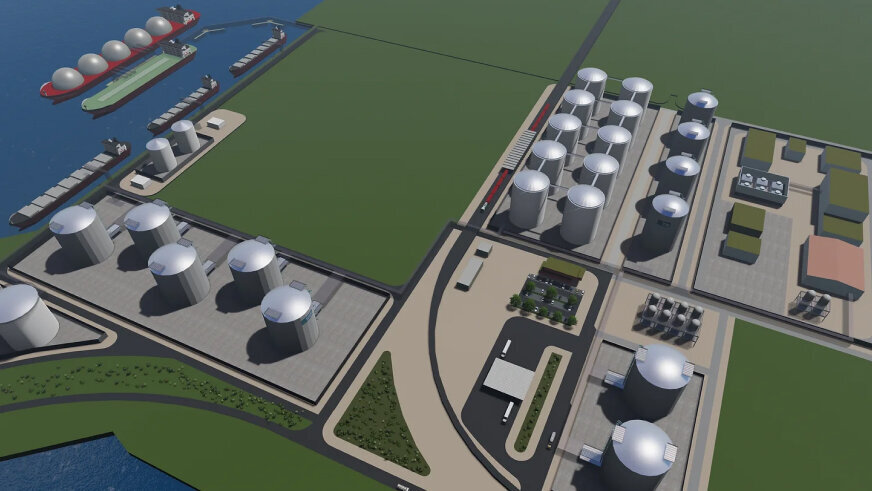

Uniper plans to construct a hydrogen storage facility with a capacity of up to 3,000 m3 in a pilot cavern in the former Krummhörn natural gas storage facility and operate it under real conditions. The knowledge gained during the two-year test phase will form the basis for larger-scale projects and the construction of commercial hydrogen caverns. Bilfinger is supporting the research project with EPCm services for the above-ground plant technology of the hydrogen test cavern. The industrial services provider had already carried out the basic engineering for the project and was selected for the new contract due to its fast, flexible and quality-oriented approach.

“We are proud to support Uniper in the realization of this pioneering project. The project highlights Bilfinger's goal of driving sustainable solutions together with our customers,” says Thomas Schulz, Group CEO of Bilfinger. “Hydrogen storage is one of the key issues in the energy transition. We can draw on our strong and transferable expertise in the gas industry and thus offer our customers added value.”

“In the future, cavern storage facilities could be used to store large quantities of green hydrogen and use it as needed. This would make a significant contribution to securing the future energy supply. Due to our long-standing relationship with Bilfinger, we are pleased that the company is supporting us in breaking new ground for our pilot project,” says Doug Waters, Managing Director Uniper Energy Storage.

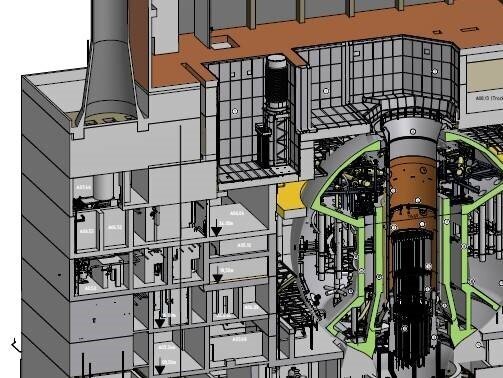

The existing storage facilities in Krummhörn were originally designed for natural gas and will have to be converted for the use of hydrogen once new public/legal approvals have been obtained. A team from the Bilfinger Engineering & Maintenance GmbH unit will provide engineering, procurement and construction management services for the planned construction of above-ground hydrogen processing facilities, including the associated peripheral equipment. This includes the planning and commissioning of pipeline systems required for hydrogen transportation between an existing natural gas field pipeline and the storage station.

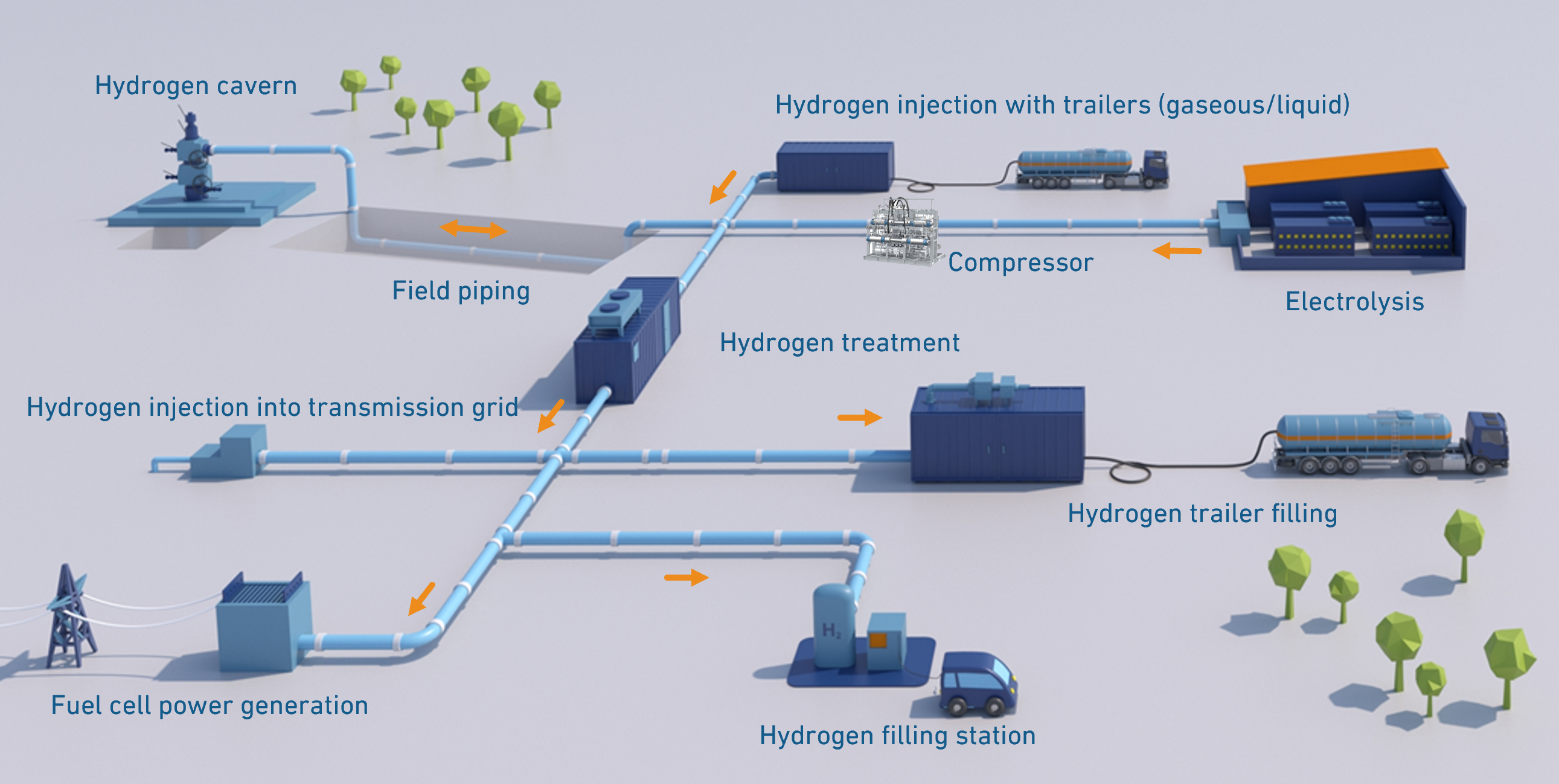

In addition, Bilfinger is coordinating the delivery and installation of a hydrogen drying system at the site, which was developed by the industrial services provider. The so-called “H2DRY” technology uses a suitable scrubbing liquid to remove water from the hydrogen by absorption, which is created during production in electrolyzers or in contact with moisture in the cavern. If the gas is too moist, this can lead to corrosion on pipes or valves. The technology enables economical and efficient hydrogen treatment on a large scale and is based on Bilfinger's many years of experience in the field of gas storage.

Uniper's pilot cavern in Krummhörn is already the second location where Bilfinger's H2DRY system is being tested: The system is currently being used at the gas storage site in Rüdersdorf near Berlin to test the future possibility of storing hydrogen in underground caverns here too.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/9/csm_MGCN_1_d66e998939.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/2023-BW_Underground-Energy-storage-Zuidwending_0623.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/One_Global_Website/References/20240507_Header_Reference_DSM.png)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/Holland_Hydrogen_1_Birdseye_view-New_Render.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/20141113_122453.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/Greenergy_3.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/IMG_9151_ABZ_Diervoeding_2016__2_.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/csm_Aspen_f2c40f8d72.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/iStock-629111916.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/TheNetherlands/Bilfinger_in_the_Netherlands/References/csm_Synthon_6e69827257.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Life_Science/Referenzen/WebRef_F_1.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Life_Science/Referenzen/WebRef_SKW_24_01_rgb_8_A5_GMP-Anlage_SKW.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Life_Science/Referenzen/WebRef_IMG_5414.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Life_Science/Referenzen/WebRef_Pharma_08_01.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Life_Science/Referenzen/WebRef_Rentschler_25_5_16_1219_bearbeitet2.jpg)

![[Translate to English:]](/fileadmin/_processed_/3/d/csm_News_Pressekontakt_KatharinaSchoenebeck_50aa1cd966.png)