- Hydrogen, an important carrier of green energy, is to be stored in large-scale salt caverns

- Bilfinger contributing engineering expertise to help offset imbalances in supply and demand of green energy

- New storage facilities are an important step for the development of the national hydrogen economy and energy transition in the Netherlands and Europe

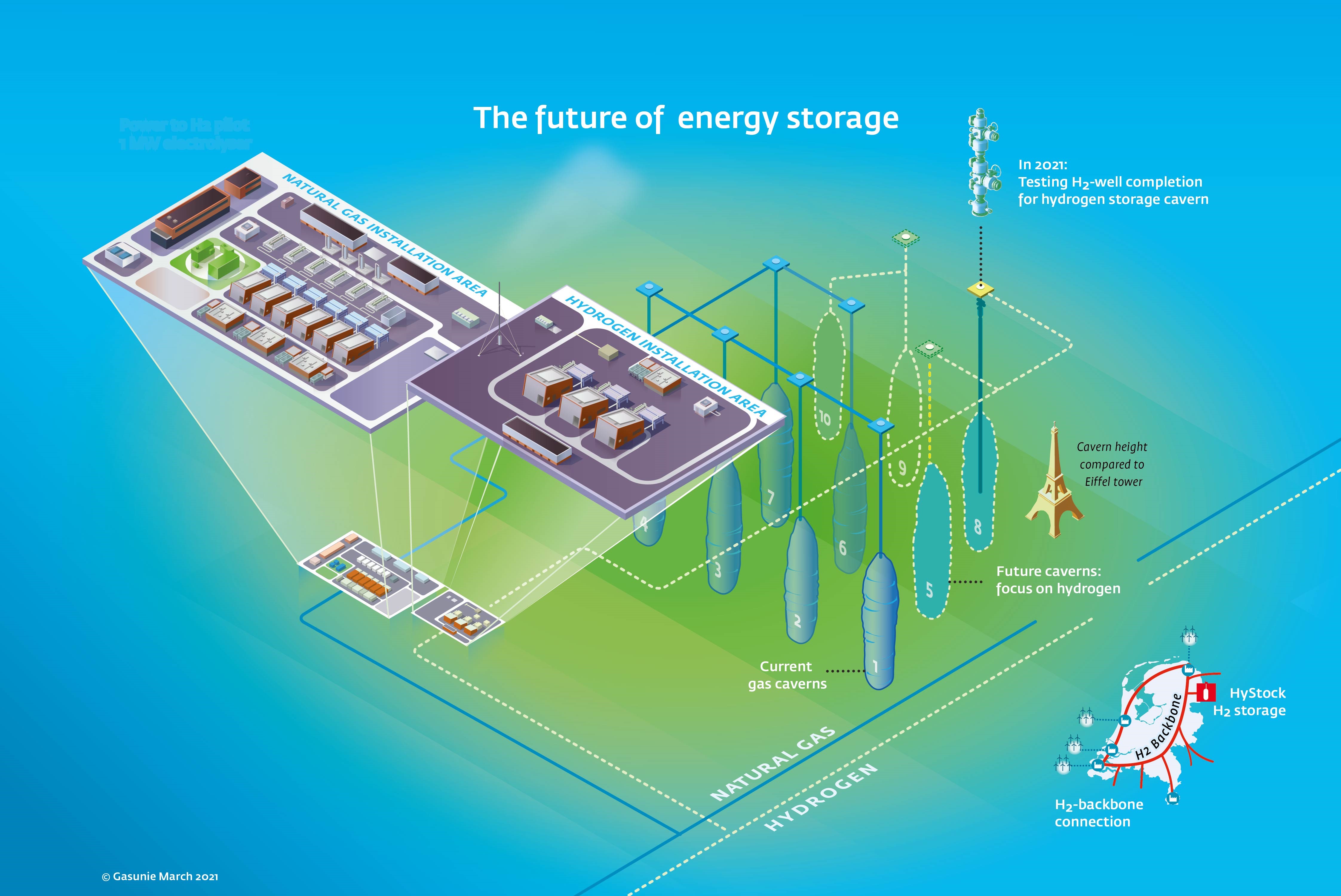

Zuidwending, Netherlands. Bilfinger is supporting Gasunie, an energy infrastructure company in the Netherlands and northern Germany, with the engineering of the HyStock project, an underground hydrogen storage facility near Zuidwending in the Netherlands. This new green hydrogen storage facility will store green energy from sources such as wind parks or photovoltaic installations that is available in the short and long-term and will offset any future imbalance in supply and demand of green hydrogen. Bilfinger Tebodin Netherlands B.V. will deliver the Basic Engineering for the entire plant (including equipment, piping, pipelines, buildings, infrastructure etc.). The facility will inject the green hydrogen into caverns into deep underground salt layers.

“Hydrogen is the most promising technology for the storage of renewable energy. We are proud to contribute to Gasunie’s HyStock project with our expertise and experience,” says Thomas Schulz, Group CEO at Bilfinger. “We support our customers across the entire hydrogen value chain from production, storage and transportation to utilization.”

Hydrogen is an important source of green energy because it has a high energy density, low capital costs and can be easily transported using the existing energy network. To store the green energy for peak demands, hydrogen is filled into caverns in deep layers of the earth. Bilfinger will provide the basic engineering for the above-ground installation. This will give Gasunie a precise picture of the storage facility with all technical, safety and environmental requirements. Bilfinger and Gasunie have been working together for many years and are benefitting from the knowledge and experience gained from former natural gas storage facilities.

“The transportation and storage of green energy via hydrogen is key to achieving reduced CO2 emissions. Given our longstanding relationship with Bilfinger, we are pleased that they are supporting us going new ways in this HyStock project,” says Bert Stouwie, Project Manager hydrogen projects at NV Nederlandse Gasunie.

The compressor stations will inject around 76 million cubic meters of hydrogen gas into each of the four planned caverns. The aim is to establish a total storage capacity of approximately 26 million kg of hydrogen. The large-scale hydrogen storage site is a completely new approach and will be managed by a multidisciplinary team at Bilfinger with extensive technical knowledge and experience. The installation and first hydrogen cavern is scheduled to be operational by 2026 and will be an important part of the hydrogen infrastructure in the Netherlands.

“We are proud to have been awarded this project, which fits seamlessly with our in-house experience,” says Jasper van der Kooi, Regional Director at Bilfinger Tebodin. “Our team is ready to work together with Gasunie to contribute to the development of the national hydrogen economy and energy transition in the Netherlands.”

From a technical and economic point of view, large-scale hydrogen storage in salt caverns is a very promising solution, both in the long and short-term. Buffering hydrogen to balance production and demand at gigawatt scale requires the injection and extraction of large amounts of hydrogen in a short period of time; therefore, caverns must be found that are particularly suitable for rapid hydrogen delivery. The caverns function as a “lung” in the hydrogen network and enable the total energy system in the Netherlands and Europe to reach the ambitious international sustainability targets.

Bilfinger offers services across the entire hydrogen value chain: from production through storage and delivery to the use of hydrogen. Services include consulting and engineering, subsequent plant construction and EPC (engineering-procurement-construction) as well as all maintenance and services. For the 1 MW HyStock pilot project that converts green energy into hydrogen, for example, Bilfinger has already contributed system integration services for the construction of the plant and was responsible for the high-voltage power supply of the proton exchange unit. Bilfinger also developed an efficient and large-scale solution for hydrogen treatment as a sustainable alternative to natural gas in Northern Germany for an innovation project.