Hydrogen

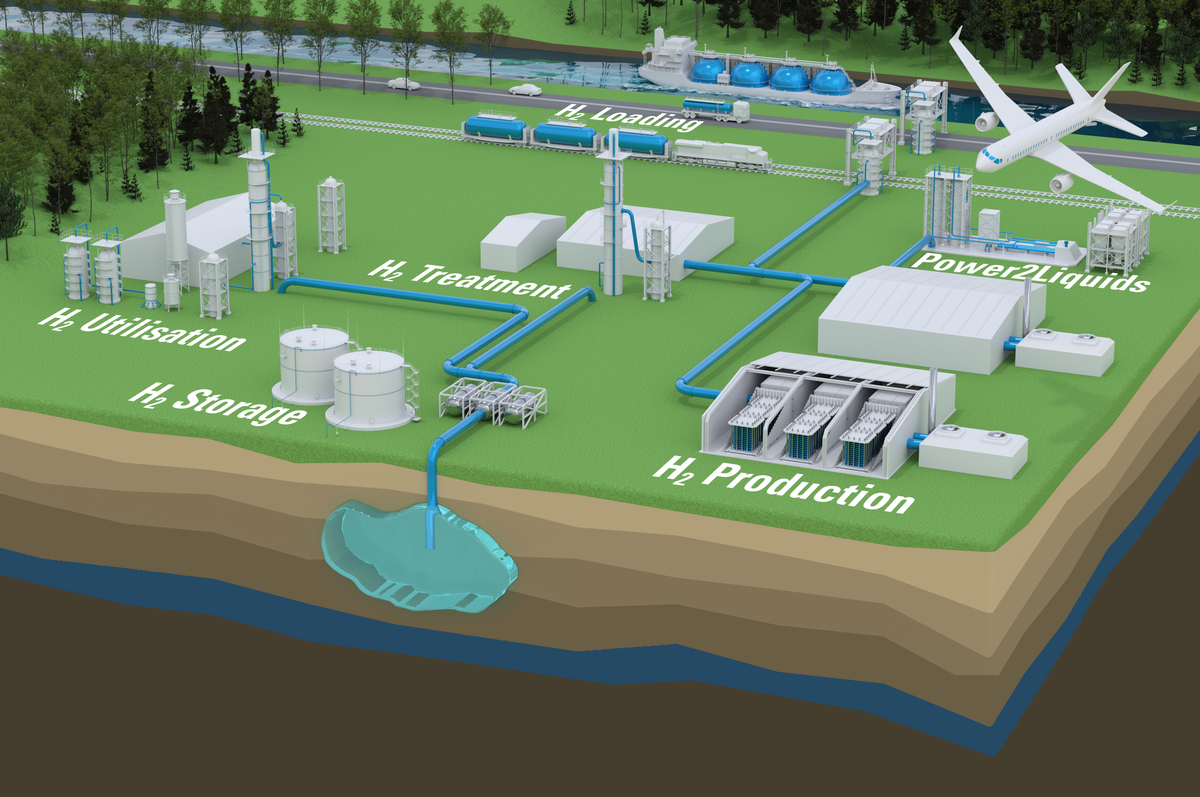

Hydrogen plays an increasingly important role in the transition to a climate-neutral energy supply. Bilfinger’s comprehensive hydrogen solutions offer industrial companies consulting and implementation services ranging from production to storage, transport and application. We bundle all necessary competencies under one roof, from project idea to realization and after-sales service.

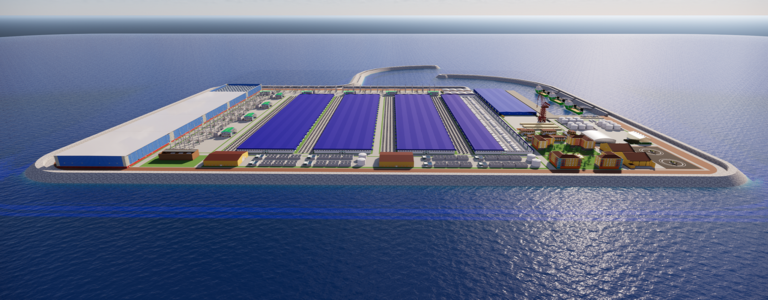

Independent planner and integrator for your hydrogen-from-water production project

Testing and conversion of existing gas infrastructure for H2-readiness

H2-Dry plant for large-scale industrial H2 drying. Other treatment processes for purifying hydrogen are also available.

Use of green hydrogen and CO2 for e-fuels.

Bilfinger offers a full range of plant construction services including project management, detailed planning and control, procurement and the execution of construction and installation work. Bilfinger can also serve as a system integrator. The advantage for the customer: they receive all services from a single source.

Product Manager H2