- Scaffolding erected at a height of 65 meters with complex structural and safety requirements

- Innovative 3D scaffolding design enhances planning reliability and transparency

- Bilfinger impresses with fast implementation under significant time pressure

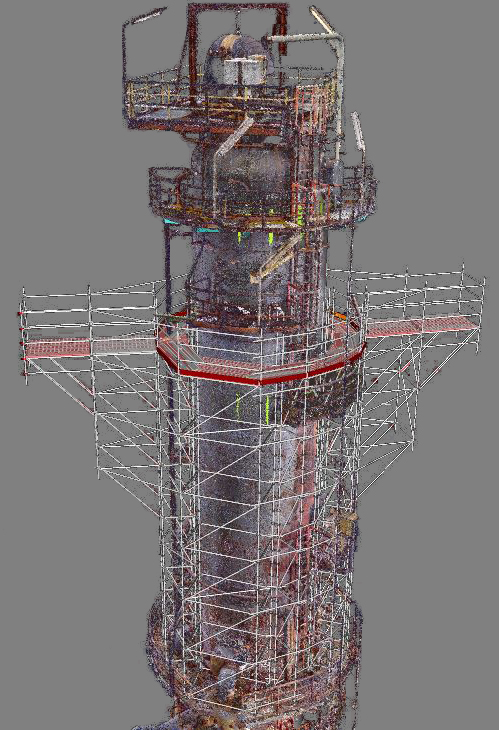

Bilfinger relies on innovative technologies for the planning, design and implementation of industrial scaffolding. For time-critical maintenance work on a section, a so-called column, at the bp refinery in Lingen, that need to be cleaned, Bilfinger was able to digitally simulate and implement the complex requirements for scaffolding in a very short period of time. Instead of an elaborate industrial scaffold over the entire length of the column, a special scaffold platform at a height of 65 meters that met the most demanding requirements in terms of structure and safety was planned and implemented under a tight schedule. Bilfinger put its digital expertise to work to help bp avert an early turnaround at the plant.

“We have been a partner at the bp location in Lingen for many years and are very familiar with the challenges at the site. This knowledge meant that we were able to simulate and implement a solution quickly and pragmatically”, says Ingo Halfter, Managing Director of Bilfinger arnholdt GmbH. “Industrial scaffolding is a critical factor for many trades. With our innovative solutions, we can ensure smooth planning and implementation as well as full transparency for our customer.”

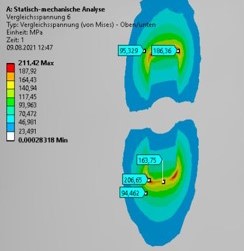

The area within the column that needed to be cleaned was a major challenge for the team from bp and Bilfinger arnholdt: the column had to be operational again in the shortest possible time to avoid substantial costs. A column is a process engineering apparatus in the form of a slim pillar and is an important part of the production process of the refinery. Thanks to the long-standing cooperation and outstanding communication between Bilfinger arnholdt and bp, a feasibility study for the scaffolding was drawn up in a very short period of time. The decisive factor here is that bp has exceptional expertise in the 3D design of facilities and Bilfinger was able to seamlessly incorporate this information into the digital simulation of the scaffolding design. In this 3D model simulation, the entire construction process can be simulated, a collision test can be carried out or material lists can be created for logistical planning and costing. The virtual preliminary planning using CAD software and the digital transfer of the data into a structural analysis program for the precise calculation of the maximum loads were particularly helpful in this project. It was only through simulation that the exact position of the scaffold legs and the weight of the structure with intelligent load distribution could be determined and the scaffold finally made available in the shortest possible time.

“Thanks to the long and close cooperation with Bilfinger, we were able to quickly work out a joint solution. Our requirements for the scaffold construction and the timeframe did not make things easy, but Bilfinger was able to step up quickly and deliver an innovative solution,” says Sarah Morris, Shift Superintendent at bp Lingen.

“The required construction was so complex that at the beginning it was not clear whether it was even possible. A credible feasibility study could only be implemented on the basis of digital simulation. This approach facilitates completely new solutions in scaffolding construction”, explains Marcel van Helden, the responsible Project Manager at Bilfinger arnholdt.

In addition to 3D simulation for feasibility studies of complex industrial scaffolding, Bilfinger uses various digital approaches to continuously optimize scaffolding construction. The bp refinery in Rotterdam uses Bilfinger's Client Portal to maintain a real-time digital overview of the amount of scaffolding on site. The Client Portal can be used to view all relevant scaffolding data, including scaffolding specifications, financial contract agreements and an overview of scaffolding locations. The focus is on transparency and efficiency. Scaffolding is used by various trades and can be a crucial cost item in plant construction and maintenance. The transparency created helps to ensure that that any unused scaffolding is dismantled in good time – thereby saving costs.

Bilfinger has been supporting bp worldwide for almost a decade in various services including maintenance, plant automation, industrial scaffolding, insulation technology, safety consulting, pipe construction and furnace fabrication.

Bilfinger arnholdt looks back on more than 115 years of company history as one of Germany's leading industrial scaffolding service providers. The company, which specializes in industrial and specialty scaffolding, in height access technology, insulation technology and corrosion protection employs over 1,500 people at its headquarters in Oberhausen and its seven other branches in Germany.