Solution partner

for the process industry

The process industry is facing significant challenges in terms of efficiency and sustainability in the short and long-term. As solution partner, Bilfinger is a driving force in the transformation of the industry to greater efficiency and sustainability in existing plants and new technologies.

We provide the expertise our customers need for the entire life cycle of their industrial plants.

We have been active in the field of industrial services for decades and are market leaders in many European countries. Together with our longstanding expertise, we offer a high quality of services around the globe. As an industrial service provider, we know exactly what our customers require. Our focus is on industrial projects, asset maintenance and plant turnarounds.

Industrial Projects

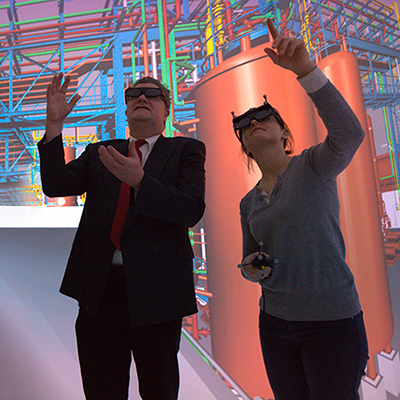

We are your multidisciplinary partner for handling your project portfolio from fairly small to large and more complex projects. Our services cover the entire project life cycle either as EPC or in individual project phases from consulting, engineering, through manufacturing to project implementation. With our broad project experience and our product - the Bilfinger Project Solution (BPS) - we support our customers in efficient and safe project execution.

In the field of energy transitions, we are involved in CCUS, hydrogen and hydropower projects, among others.

Asset Maintenance

Using the right asset strategy, we increase the efficiency and thus the sustainability of existing plants as well as optimize maintenance costs. Our services include analysis and consulting, engineering, planning and implementation of maintenance, as well as improvement and optimization. We cover all trades such as static and rotating equipment, insulation, scaffolding and corrosion protection (ISP), condition analysis and monitoring. This is supported by digital services with mobile applications.

We have bundled our many years of experience as a maintenance partner to the process industry in the Bilfinger Maintenance Solution (BMS).

Plant Turnarounds

In the process industry, it is necessary to shut down plants in regular, recurring periods. These shutdowns are required by law or production technology or are used to improve the performance of the plant. With the Bilfinger Turnaround Solution (BTS), Bilfinger ensures efficient risk management and professional execution of the work by providing best practice guidance.