Small magnets to secure

large projects

Installation is simple and the materials required are common and readily available"

Milos Hejtmanek looks back on a 35-year career in engineering. He has been working as a structural engineer at Bilfinger Tebodin for 25 years and has participated in numerous projects worldwide. With his extensive expert knowledge, he has now developed an unconventional method to ensure the safety of everyone in the event of an accident.

He first got the idea during a project for a customer in the Czech Republic who asked Bilfinger Tebodin for support in the planning of a new production plant. The plant comprises underground premises with reinforced walls in which flammable substances with a high risk of explosion are processed. A special fastening system is used to ensure safety of explosion walls in order to release the internal overpressure generated by an explosion as quickly as possible. Up to now, these walls have mostly been made of wood or glass materials and fastened to resistant building structures with standard fasteners (screw, bolt, nail, pin, etc.). The problem was to determine the exact force at which the fasteners would break and release the wall.

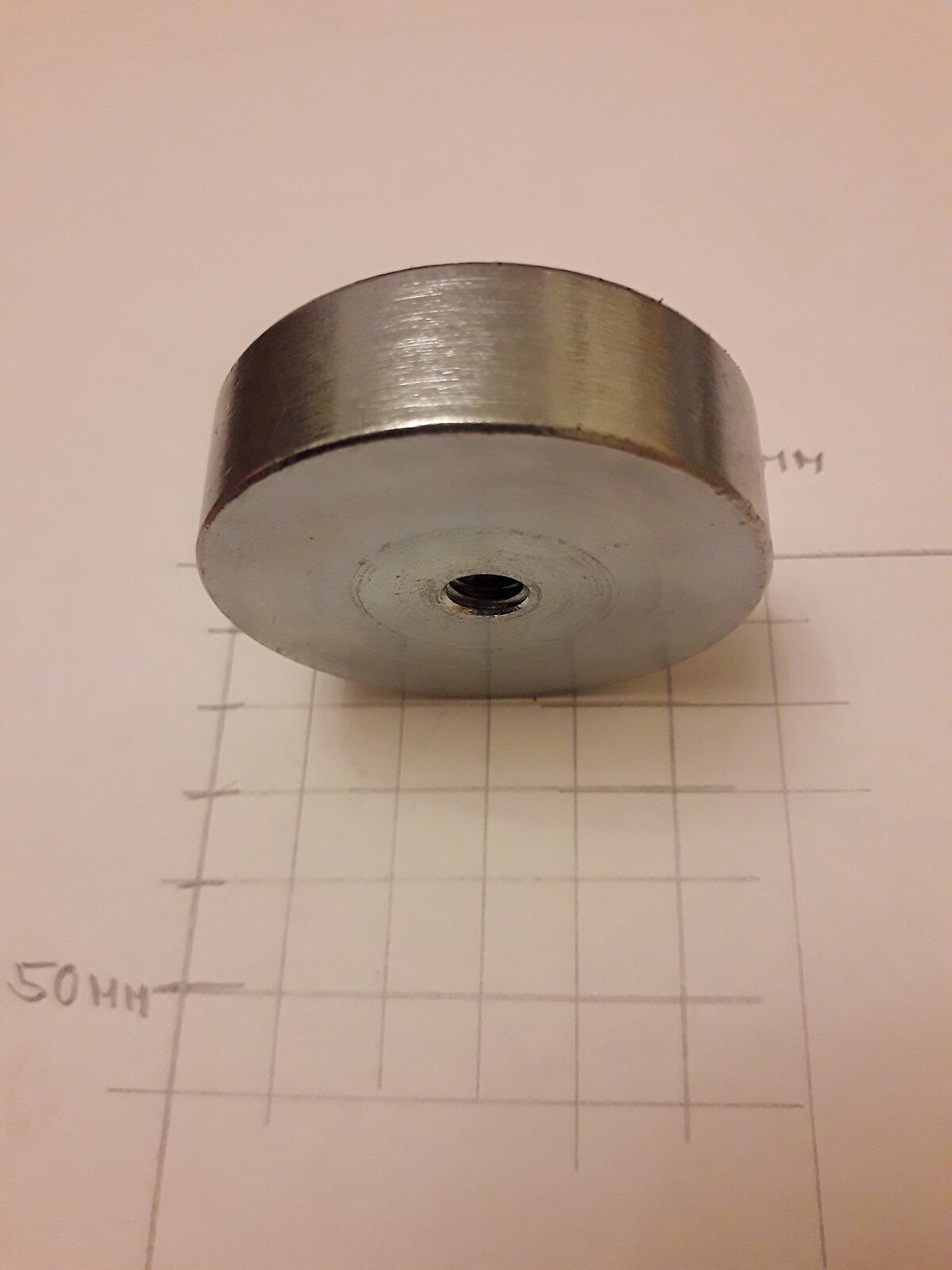

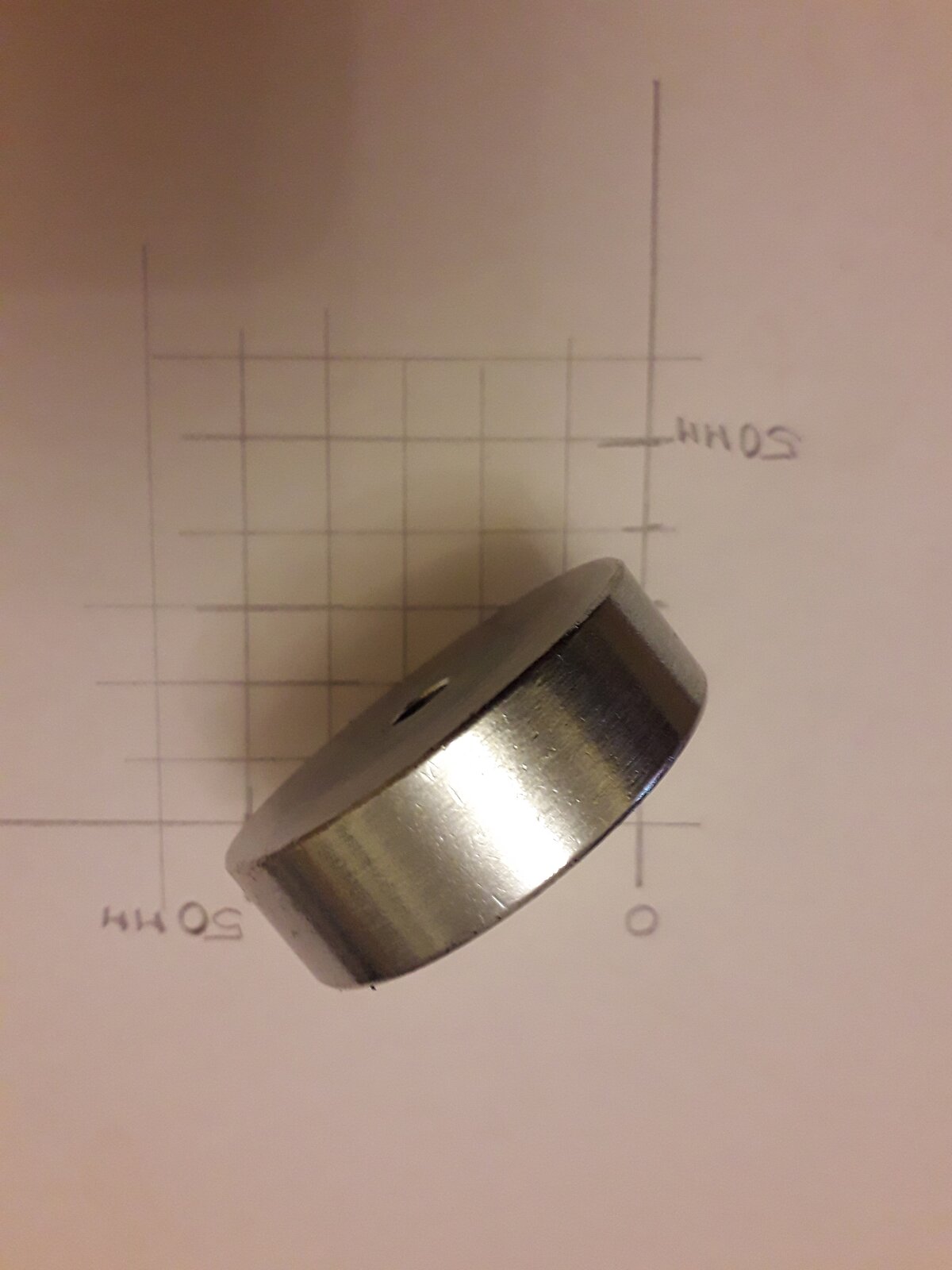

Milos found a suitable, elegant solution to this problem: instead of standard fasteners, neodymium-strong magnets can be used. These magnets are adapted exactly to the breaking force, depending on the size and distance from the steel bearing frame, which is part of the pressure-resistant explosion structure. If the magnets are suitably arranged, the direction of wall movement after an explosion can also be controlled.

This solution offers several advantages. First, it is virtually independent of the type of the protective wall. The standard requirement is a minimum dead weight. Furthermore, the use of magnets allows the attachment of typical lightweight sandwich panel walls as well as glass or wooden walls. "If you can calculate the exact triggering pressure of the wall, you can better predict the maximum internal overpressure during the explosion and you use less material," says Milos. "Installation is simple and the materials required are common and readily available". Another advantage of this technical solution is the thermal insulation. The glass or wooden walls that have been used so far are thin, which leads to low room temperatures in winter. This has a negative effect on the comfort of the people working inside.

With Milos' innovative solution, money for the construction and operation of buildings can be saved and the safety of buildings can be ensured. Other manufacturers who handle explosive substances are now also requesting Milos’ customized solution. Since 2018, the fastening method has been protected by the Patent Office of the Czech Republic as a utility model (small patent), owned by Bilfinger Tebodin.