- Temporary decoupling of electricity and heat production ensures sustainable operation and security of supply

- Increased efficiency through pioneering patented dual-zone technology

- Future operation with green hydrogen planned to ensure sustainable energy supply

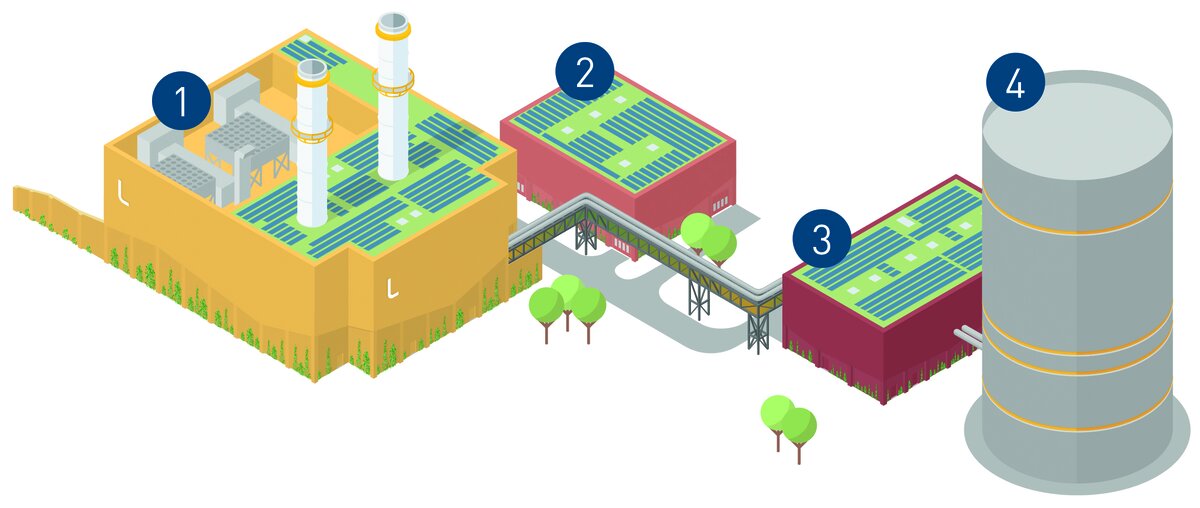

Leipzig, Germany. A new landmark towers over Leipzig: the district heating accumulator of the Leipzig South combined heat and power plant (CHP). Visible from afar, this engineering feat is also a symbol of Germany's energy transition. The 60-metre-high steel structure is designed to store large quantities of sustainably generated heat and make it available at times of peak demand. Leipzig's municipal utilities, Stadtwerke Leipzig GmbH, are relying on innovative two-zone technology from industrial services provider Bilfinger. At the end of 2020, Bilfinger was awarded the contract for the design, supply, turnkey construction and commissioning of the two-zone accumulator and the balance of plant (BoP). The contract has now been successfully completed.

The district heating accumulator acts like a giant battery, increasing the flexibility of the power plant and acting as a buffer. It can absorb excess energy and release it back into the district heating network during peak demand periods. This temporal decoupling of electricity and district heating production enables flexible, economical and climate-friendly use of the Leipzig gas turbine combined heat and power plant, as surplus energy is not lost. Thanks to Bilfinger's patented dual-zone technology, up to 42,300 cubic meters of water can be stored at a temperature of up to 120 degrees Celsius, reducing the need for reheating and making the supply particularly energy efficient. The Leipzig district heating accumulator is one of the first five facilities in Germany to use this innovative technology.

“As a solution partner to the industry, we aim to play an active role in shaping the transformation of energy supply towards sustainable solutions. District heating storage systems are a central building block in this process, and their efficiency is further increased by our unique two-zone technology,” says Thomas Schulz, Group CEO at Bilfinger.

Bilfinger legal entity Bilfinger Industrial Services Austria acted as general contractor for the planning, construction and commissioning of the district heating storage facility and its integration into the power plant. The extensive services included steel construction, piping, electrical equipment and the installation of 14 pumps.

The heat accumulator in Leipzig is particularly efficient thanks to its two-zone technology based on the so-called Hedbäck principle, for which Bilfinger holds the patent.

In the two-zone storage system, the storage volume is divided by an intermediate roof into an upper and a lower zone, which are connected by pipes. The upper zone contains water at a temperature of 60 to 99 degrees Celsius, which generates pressure due to its own weight. This keeps the water in the lower zone, which is over 100 degrees, from boiling. The two-zone design makes it possible to store water at temperatures of up to 120 degrees Celsius in a pressureless tank. Bilfinger has already built heat accumulators of this type in Nuremberg, Kiel, Duisburg and Heidelberg. The storage facility in Leipzig has a capacity of around 1,800 megawatt hours (MWh), which is sufficient to ensure the main supply of the local district heating network for a limited period of time if required.

“We are driving forward the structural change in the energy industry in Leipzig and want to offer our customers environmentally friendly and secure energy at attractive prices. The heat accumulator built with Bilfinger's unique know-how makes an important contribution to this,” says Karsten Rogall, Managing Director at Stadtwerke Leipzig GmbH.

With the construction of the new CHP Leipzig South, for which the foundation stone was laid in 2020, the city of Leipzig is securing the energy supply of the booming Saxon economic metropolis and at the same time making an important contribution to achieving the city's climate targets. The power plant will use gas as a bridging technology in its highly efficient turbines, but is designed to be able to run on green hydrogen in the future.

In April 2023, Bilfinger completed the heat accumulator in Leipzig. It has since been successfully integrated into Leipzig's district heating network. Bilfinger's other current orders in the district heating sector include the supply of electrical and automation technology for the district heating network of the Mannheim-based energy company MVV, as well as piping construction for the new district cooling center in Munich.

![[Translate to English:]](/fileadmin/_processed_/3/d/csm_News_Pressekontakt_KatharinaSchoenebeck_b48271ab3e.png)