- Company develops software for more process efficiency in biotechnology

- "Quality by Control" makes product quality controllable during production

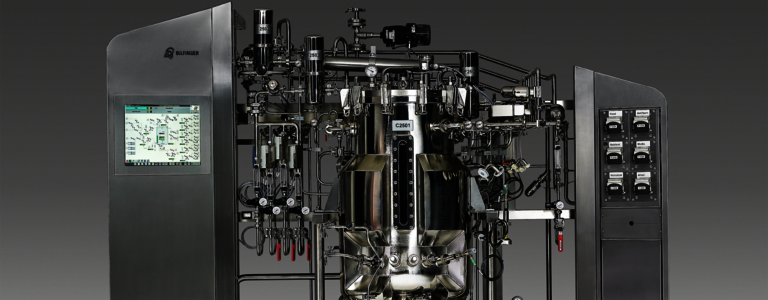

Bioreactors are at the core of many processes in the biopharma sector. But there is one major challenge: Many decisive quality features cannot be directly measured during production of an active ingredient. Whether the desired result is achieved at the end of the process can therefore only be determined by means of expensive analyses of the end product. This will change with the advent of a quality monitoring and control software that is currently being developed by Bilfinger subsidiary Bilfinger Industrietechnik Salzburg GmbH in cooperation with the Department of Biotechnology at the University of Natural Resources and Life Sciences, Vienna. The software makes it easier, among other things, to integrate spectroscopic measurement procedures and to use mathematical models to monitor and control the processes in the reactor in real time.

The most common procedure to date of the review of processes in bioreactors is called "Quality by Testing" - the quality can only be determined at the end of the process. For biotech and biopharmaceutical companies, this makes the path to market approval longer and more expensive. And the quality management in production is especially complex as a result.

"With our solution, we are now tackling the fundamental problem", says Gerald Berghammer, Head of Project Development Plants & Systems at Bilfinger Industrietechnik Salzburg. "Our new procedure 'Smart Bioprocessing' builds on 'Quality by Control' so that the product quality can be predicted and influenced already in the reactor. This will allow companies to organize their production capacities much more effectively in the future."

The most important reactions in a bioreactor generally take place inside the production cell lines. Against this backdrop, it is very difficult to get a direct measurement of meaningful process variables. In addition to the standard sensors such as pH, temperature, pressure or dissolved oxygen, non-invasive spectroscopic measurement methods such as 2D fluorescence, near infrared spectroscopy or Raman spectroscopy are therefore increasingly being used in bioprocesses. With the help of mathematical models, these methods can deliver relevant quality information. This is where the software platform developed by Bilfinger comes in: Various measurement data is combined and, on the basis of mathematical models, evaluated so that conclusions can be drawn regarding the current status of an ongoing process and the probable product quality. In the case of deviations, the processes can be influenced in a targeted manner with control measures, so that the product quality is within the prescribed tolerances in the end.

Bilfinger is currently programming the modularly designed software platform for implementation of the "Quality by Control" concept. At the same time, the functions are being thoroughly tested. Market launch for the first modules is expected in the second half of 2018. The developers are planning the first fully-functional version of their monitoring and control software already for the end of this year.