Demonstration plant: Industrial drying of hydrogen

Hydrogen has to be dried before it can be converted into electricity or fed into the transport grid. But what is the best way to dry hydrogen industrially? And what are the technical requirements for the process? A demonstration plant currently being developed and built by Bilfinger is seeking the answers to these questions.

There are a number of processes for drying hydrogen. These include, for example, the absorption, adsorption, condensation and membrane separation processes. It is not entirely clear, however, which process offers the greatest advantages for the industrial drying of hydrogen, ensuring that, once it has been dried, it can easily be converted into electricity or fed into the transport grid. Experience regarding the design and manufacture of large-scale plants for industrial hydrogen drying is currently limited.

GemeBilfinger is therefore participating in a hydrogen drying research project together with the Institute of Thermodynamics at Leibniz University in Hanover and EWE Gasspeicher. The goal of the project is to build a demonstration plant that can dry hydrogen on a large scale and highly economically. The project is being funded by the German state of Lower Saxony and is considered an important milestone in the further development of hydrogen technology.

Drying by absorption

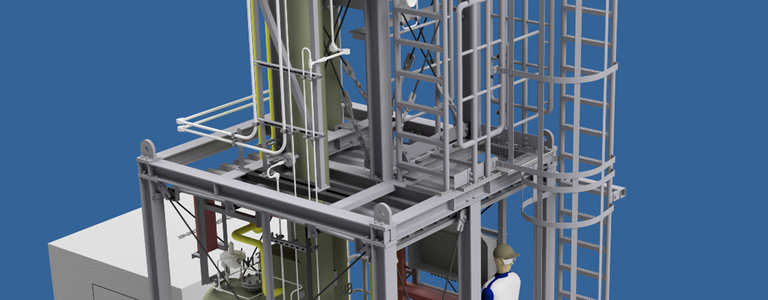

The demonstration plant is currently being developed and built at Bilfinger Engineering & Maintenance‘s Cloppenburg site. It is based on an innovative process that dries hydrogen by absorbing moisture using a suitable scrubbing liquid. Bilfinger is benefiting from its many years of experience in the development of natural gas plants, since very similar processes are used in these plants. They have been operating for decades with a high degree of reliability and efficiency.

The plant will be delivered to Rüdersdorf in Brandenburg in early 2023. There, it will first undergo extensive testing before being integrated into the hydrogen storage plant planned by EWE Gasspeicher. The goal is that this facility will enable hydrogen to contribute to the energy supply the way natural gas does today. Scientific support for this project is being provided by the Institute of Thermodynamics at Leibniz University in Hanover.

Milestone for an efficient hydrogen economy

“The implementation of this project is a major step forward for the energy transition”, says Lower Saxony’s Environment Minister Olaf Lies. “Decentralized hydrogen drying by absorption for gas storage and feeding into the grid is an essential step for the hydrogen economy. With this technology, hydrogen can be treated economically on a large scale, thus enabling the integration of renewable energies into our energy system. This means that hydrogen produced using wind and solar power, or hydrogen soon to be stored in caverns, can be fed into the transport grid.”

We are putting our decades of experience in building natural gas drying plants all over Europe to good use with this innovative development for the energy transition powered by green hydrogen.”"

![[Translate to English:]](/fileadmin/_processed_/f/c/csm_400x400_Ulrich_Trebbe_V2_Website_9e9f59d761.png)

Product Manager H2