- Long-term cooperation initiated at Cologne location

- Objective: Increase in quality and efficiency through the bundling of engineering services

- As a solution partner, Bilfinger meets need for full-service solutions

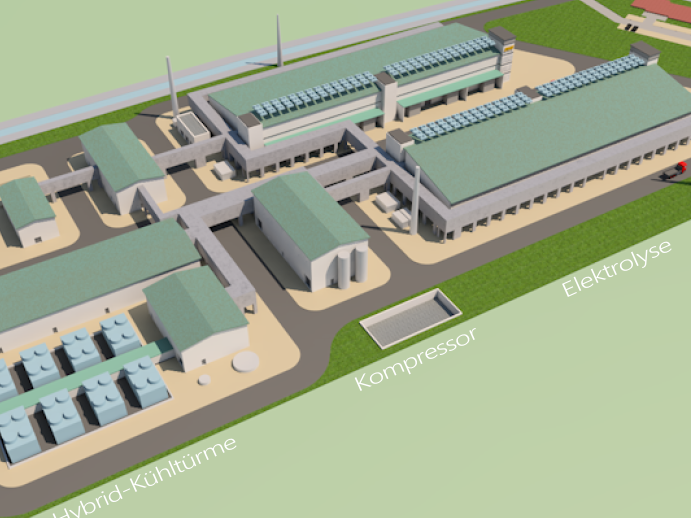

Cologne. Bilfinger has become the first company to win a strategic engineering alliance partnership with chemical company INEOS at the Cologne site. The contract was signed in September 2022 and runs for a period of three years, with the objective of a long-term cooperation.

The primary focus of the cooperation is to increase quality and efficiency by bundling all engineering services with one alliance partner, thereby eliminating the need to coordinate a large number of smaller service providers. The decision in favor of Bilfinger was made following a thorough selection process in the field of engineering at the Cologne site and thanks to the comprehensive portfolio of solutions and its expertise as a multidisciplinary engineering service provider.

“The strategic partnership with INEOS in Cologne highlights our commitment to being a solution partner for efficiency and sustainability for energy-intensive industries”, says Thomas Schulz, Group CEO at Bilfinger. “Our customers increasingly require the support of competent and capable partners when it comes to implementing their efficiency and sustainability goals. Bilfinger is well-positioned to meet this need.”

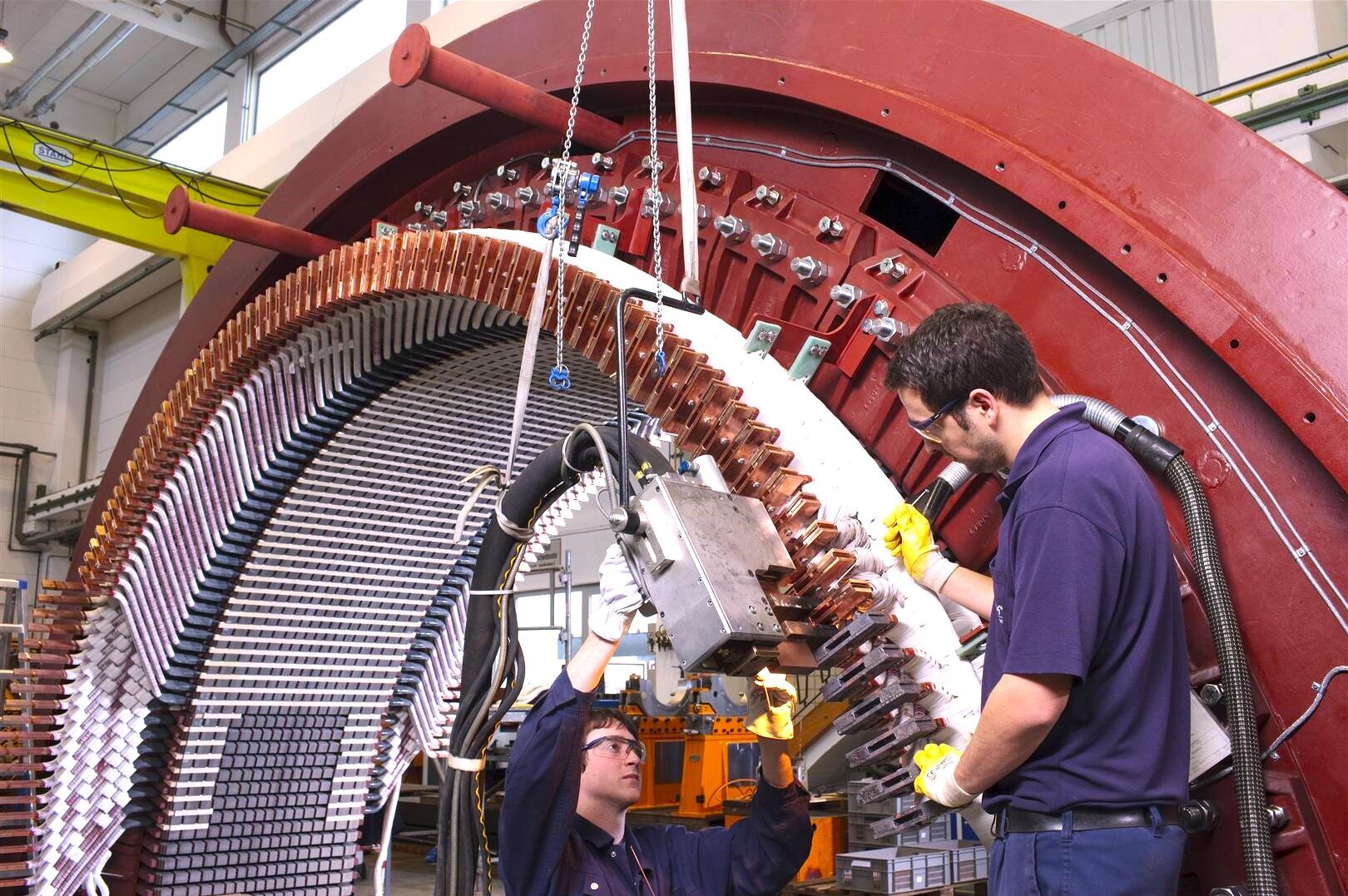

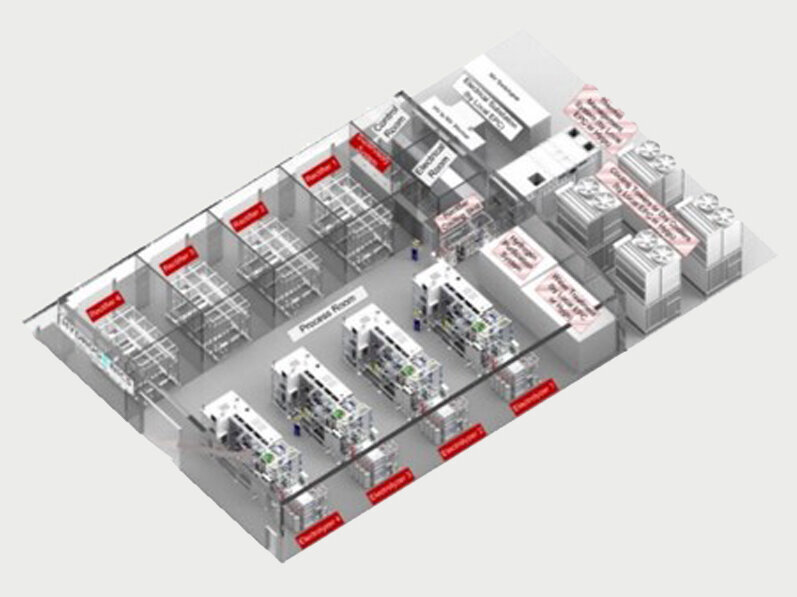

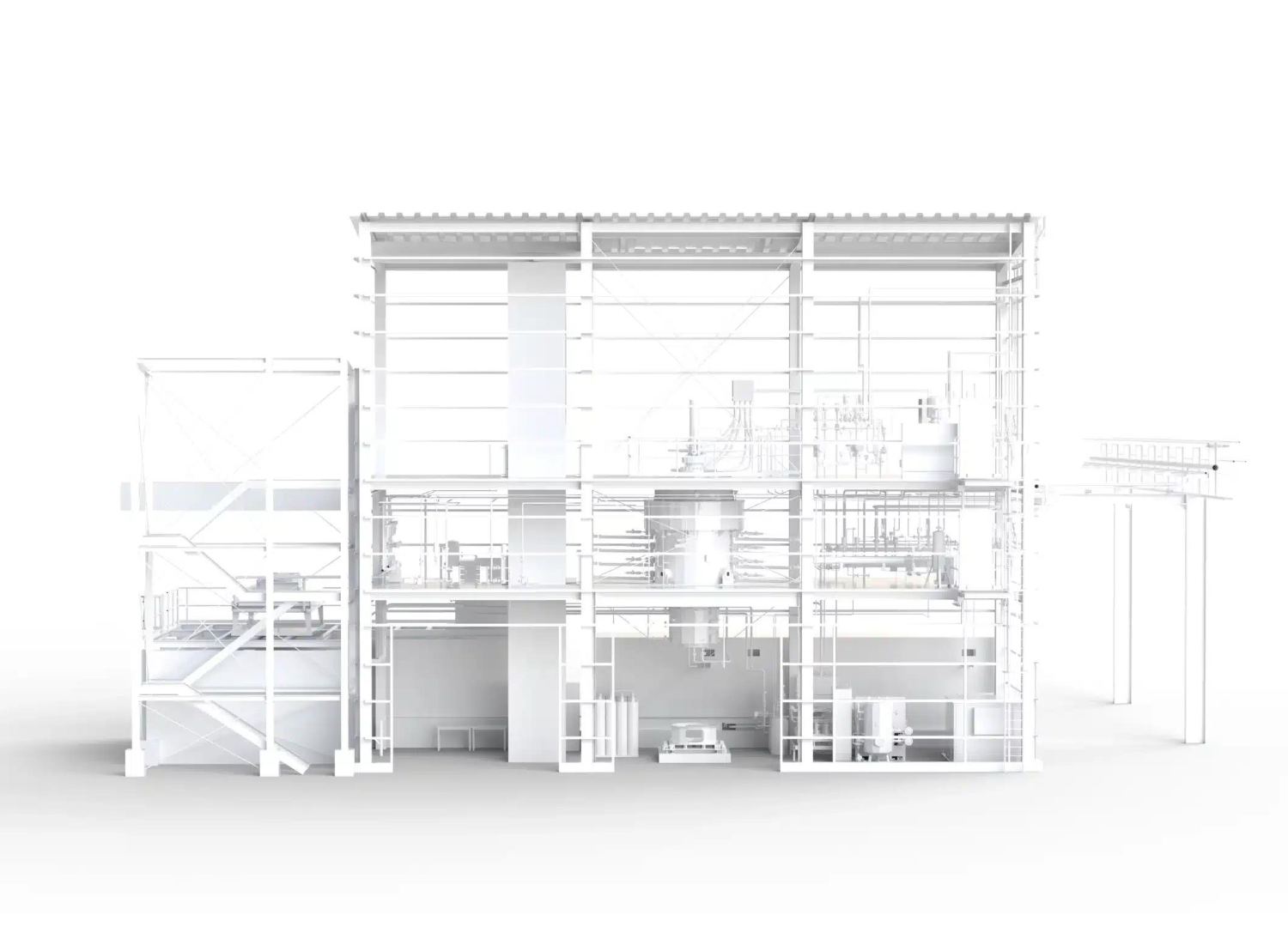

The size and extensive resources of the international Bilfinger Group made it possible to create a qualified team of engineers from the areas of electrical instrumentation and control (EI&C), operating technology and project management within a very short period of time. Within the scope of the partnership, a team from Bilfinger Engineering & Maintenance GmbH provides project management and technical support for brownfield projects with a total investment volume in the single-digit million euro range.

“The cooperation based on a spirit of trust during the selection process, as well as Bilfinger’s overall thorough understanding of the kinds of issues we face and the material to be worked on were all factors that resulted in us choosing Bilfinger as our alliance partner”, says Dr. Harald Joost, Head of the Engineering Unit Studies & Projects at INEOS in Cologne. “We value Bilfinger as a strong partner, one that opens up opportunities for us to increase the efficiency of our projects and consequently operate more cost-effectively as well as more sustainably.”

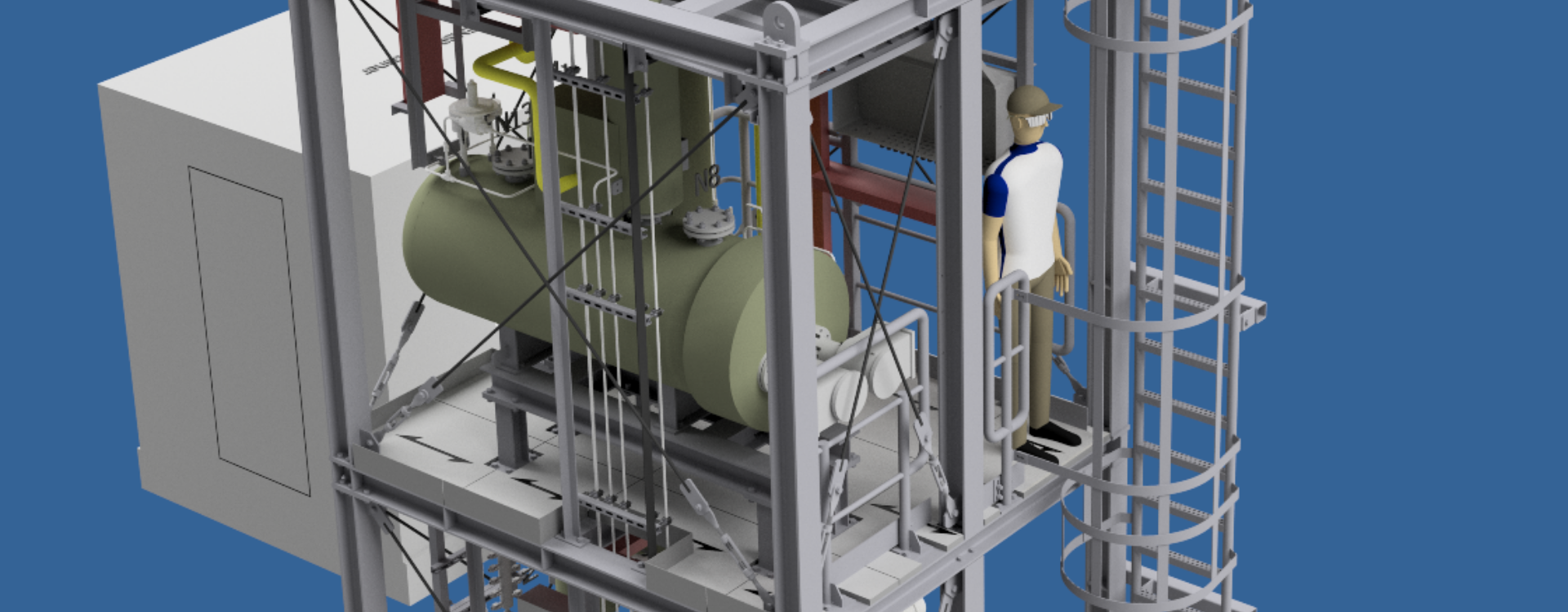

“As an alliance partner, Bilfinger behaves like the customer itself," explains Patrick Töbel, Regional Manager North at Bilfinger Engineering & Maintenance GmbH. “This means that our team has to find solutions independently by working out the scope of services, developing concepts and obtaining the necessary information. This kind of cooperation saves our client valuable time and ensures consistently high-quality across all levels of work.”

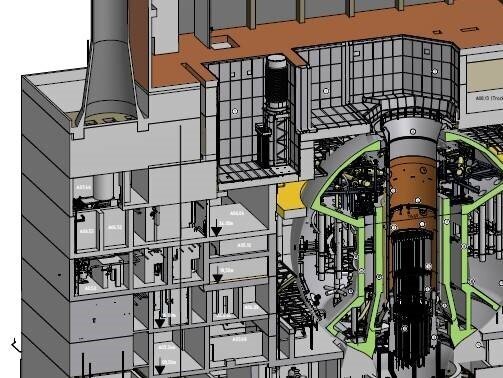

A recent example of the team’s efforts is the concept for a major distillation column shutdown that is being carried out this month. Among other things, the steel structure was inspected and a concept was developed for the erection and demolition works. Planning activities in the areas of fittings and piping construction are also included in the scope of services. In addition, as a provider of full-service solutions, Bilfinger is in a position to supply all relevant trades from a single source if required for the implementation of work on the plants.

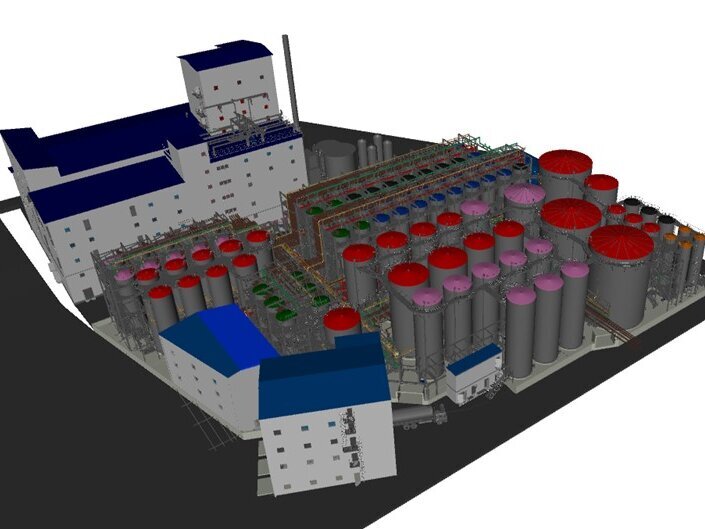

In addition to the alliance partnership team of seven engineers there are further Bilfinger employees permanently deployed at the INEOS site in Cologne for maintenance work. The industrial services provider also provides support with additional personnel for the peak periods of major turnarounds. In addition to the plant in Cologne, Bilfinger also supports INEOS with maintenance services at other sites throughout Europe, including the Zwijndrecht and Doel sites in Antwerp, Belgium, Grangemouth, Scotland and Bamble, Norway.

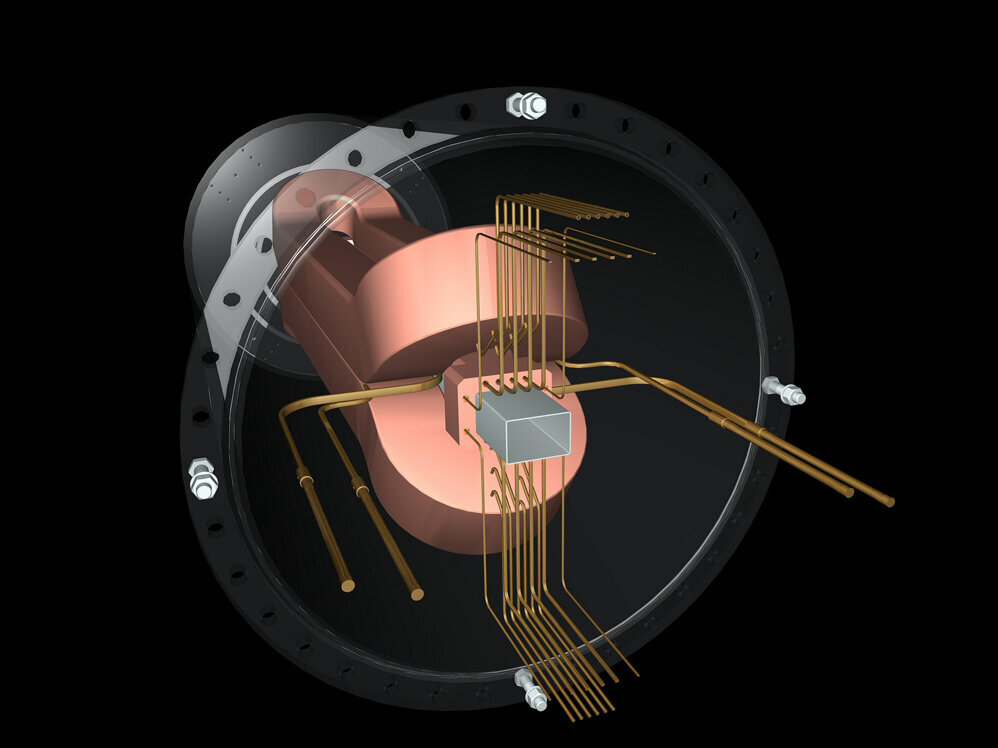

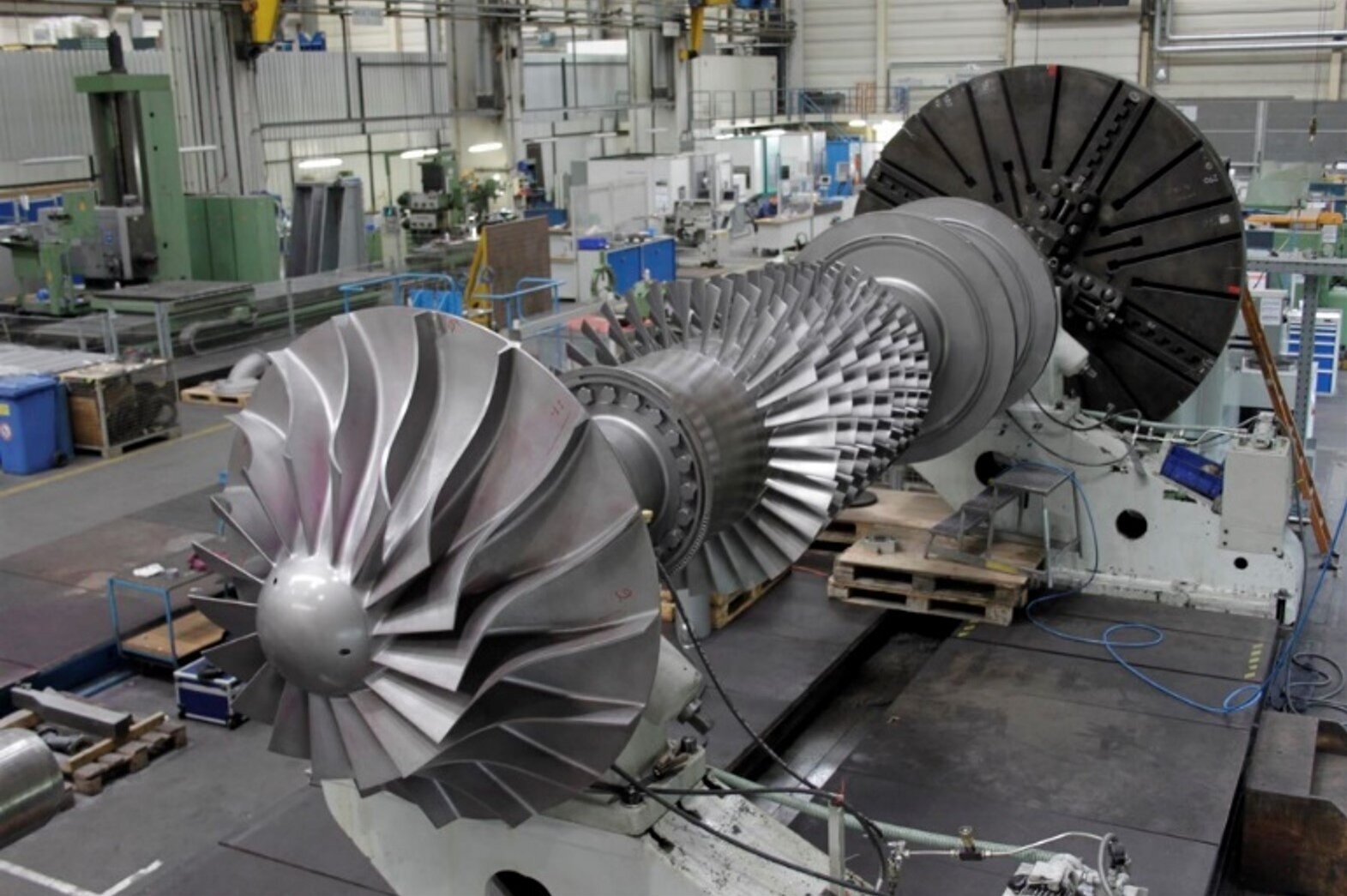

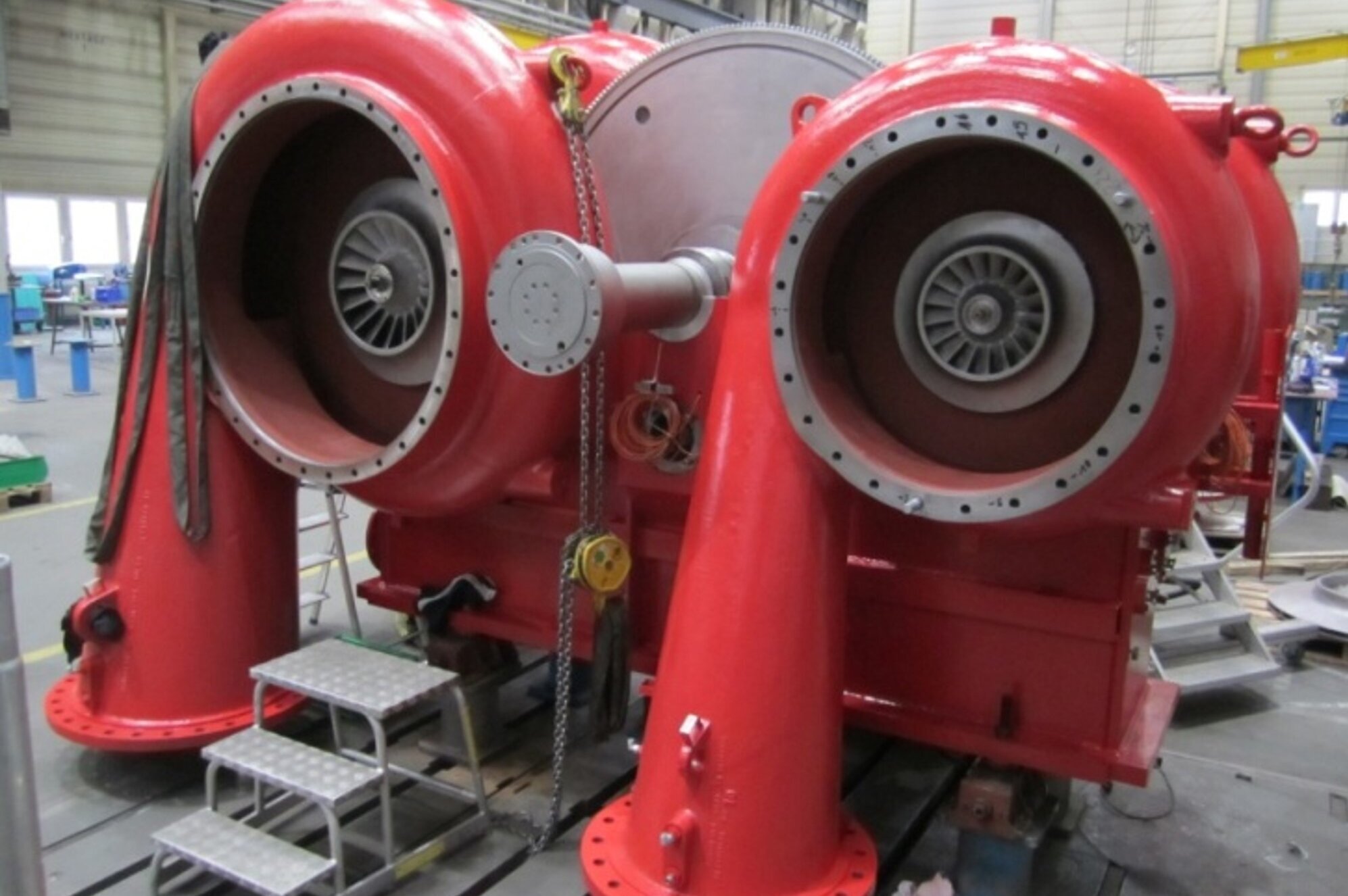

INEOS in Cologne is one of the Swiss-British chemical and energy group's largest sites, with a total of 21 plants. The petrochemical site is an important raw material supplier for the chemical industry. One of its main products is ethylene, which is produced from naphtha in a cracking process in the two large cracker plants. The Cologne site also produces other raw materials that serve as basic components for the manufacture of plastics, rubber and fibers as well as other chemical products.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/8/csm_Header_Reference_BPLingen_219b6c2cd4.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/0/csm_Bruecke_shutterstock_schmal_Ret_c5e36c8037.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/One_Global_Website/Services/references/Wasserkraft_Referenz_KW_Reisach.png)

![[Translate to English:] [Translate to English:]](/fileadmin/One_Global_Website/References/Wasserkraft_Referenz_PumpspeicherwerkHerdecke.png)

![[Translate to English:]](/fileadmin/_processed_/3/d/csm_News_Pressekontakt_KatharinaSchoenebeck_50aa1cd966.png)