Electrical, Instrumentation and Control (EI&C)

Bilfinger supports process industry customers with comprehensive electrical, instrumentation and control technology (EI&C) services. Whether your business is energy, chemicals, oil and gas, or food processing, you can count on our manufacturer-independent expertise across all EI&C phases.

Our EI&C services

Our professionalism and experience provide customers with robust, safe and efficient systems. How we support:

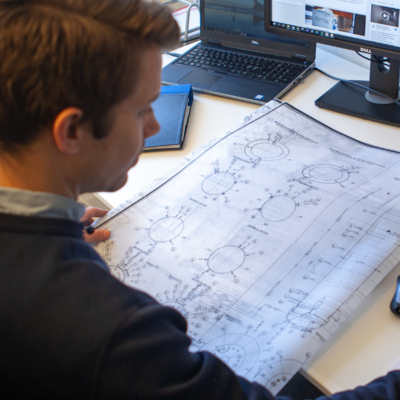

We develop concepts for electrical installations, measuring instruments and control systems and prepare circuit diagrams and schematics for electrical circuits. Our experience in developing control strategies for process automation ensures peace of mind.

We install electrical wiring, control panels and equipment. Measuring instruments are mounted and calibrated to measure variables such as pressure, temperature, flow and level.

We can select, install and maintain instruments to measure and monitor process variables. Our services include the programming and configuring of programmable logic controllers (PLCs) and supervisory control systems (DCS) for process control. In addition, we develop control strategies to maintain defined process parameters.

The appropriate instruments are selected, installed and maintained to ensure the measurement and monitoring of process variables. We calibrate and validate the instruments to confirm that the accuracy of the measured values is continuously improved. In addition, we build Supervisory Control and Data Acquisition Systems (SCADA) to collect and analyze data. We are developing Human-Machine Interfaces (HMI) systems for operators to interact with and control processes.

To verify the safety of critical processes, we participate in hazard assessments and risk analyses. Safety measures are implemented to protect personnel, equipment and the environment.

We perform regular maintenance and servicing of E&IC systems during plant operation. Potential faults and malfunctions in control and measurement systems are diagnosed and resolved.

Our energy-efficient solutions optimize power consumption. We monitor energy usage and identify additional opportunities for optimization.

Leading process companies rely on our expertise to help them integrate E&IC systems with information technology (IT) to analyze, share and manage acquired data. Cybersecurity measures can be implemented to protect against cyber threats.

EI&C Installation and Maintenance

Our EI&C technology offers comprehensive services for production plants in the process industry. As an experienced service provider, we know about the sensitivity of modern production plants and the importance of professional installation and maintenance.

- On-site maintenance, inspection, repair and troubleshooting of electrical, instrumentation and control equipment, e.g. field devices, PLCs/PLCs, actuators, pneumatic and electric devices, electric motors, etc.

- Assumption of responsibility for electrotechnical systems for agreed areas of support

- EI&C operational support including specialist engineering services

- Programming and modification on programmable logic controllers (PLC)

- Erection of complete EI&C plants (new plants or conversions)

- Site management, project planning, installation, installation supervision

- Qualified final installation inspection (loop check)

- Preparation of the required documentation

- Testing of systems/work equipment requiring monitoring

- DGUV V3 testing of stationary and mobile electrical equipment

- Lightning protection and machine tests according to VDE

- Testing of electrical systems and equipment, e.g. power and lighting systems in hazardous and non-hazardous areas

- Detection of thermal anomalies on electrical and mechanical equipment during ongoing production without influencing production or plant availability

- Preparation of investigation reports and consulting in case of significant deviations

- Ensuring optimum operability of process engineering equipment 24 hours / 365 days a year

- On-site troubleshooting of electrical, instrumentation and control equipment

- Cabling of data networks including installation of passive components such as distribution panels, RJ modules, junction boxes, intermediate and main distribution cabinets

- Troubleshooting in existing network infrastructures

- Network acceptance measurements

- Assembling of connectors including acceptance measurements and documentation

- Splicing of multimode and singlemode fibers

- Troubleshooting in the fiber optic network

- Acceptance measurements (attenuation measurement, OTDR measurement) including documentation

- Delivery of all fiber optic components (connectors, pigtails, splice boxes, etc.)

- Visual inspections, commissioning support

- Functional tests, preparation of test documentation

- Testing of equipment for plant safety (EzA)

- Lighting measurements according to DIN or ASR

- Consulting, planning, project engineering

- Installation, programming and commissioning

- Troubleshooting

- Maintenance and servicing

MSR Technology

We look after ongoing production operations through inspection, maintenance, efficient repair, and professional testing and calibration.

Our strengths lie in providing customized solutions for both routine work and special cases. Thanks to our involvement in national and international standardization committees, we are very familiar with the applicable requirements.

- Manufacturer-independent calibration and repair of electronic and mechanical weighing systems (incl. explosion-proof devices), as well as truck and rail scales

- DAkkS on-site calibration from 5 g to 6,000 kg

- Factory calibration up to 120 t

- Planning and consulting for all aspects of weighing technology

- Application and commissioning support

- Coordination of calibration dates and calibration support

- Testing and calibration of filling systems

- Calibration of container and silo scales by means of mass dosing stations

- Testing according to manufacturer's specifications or customer-specific SOP

- Testing of linearity, corner load, reproducibility

- On-site repair or in our workshop

- Manufacturer-independent repair of pressure and level transmitters (incl. explosion-proof devices)

- Calibration of pressure transmitters, manometers and recorders

- Parameterization and adjustment

- Range 0.015 mbar abs. to 1,600 bar

- Room pressures in the Pascal range

- Calibration service on site

- Commissioning support

- Manufacturer-independent calibration, adjustment, repair of all flow measuring methods, flow transmitters (incl. explosion-proof devices)

- Nominal diameter range from DN04 - DN200

- Measuring range 1 l/h - 400 m³/h

- DAkkS calibration (test medium water)

- Calibration service on site

- Application and commissioning support

- Configuration of the devices

- Comparative measurement on pipelines (ultrasonic clamp on)

- Variable area flowmeter from stock

- Multi-vendor calibration and repair of laboratory weighing systems and pipettes, dispensers and dilutors

- DAkkS calibration laboratory (in-house) from -30° to 500°C

- Factory calibration in the range from -196° to 1100°C

- On-site calibration

- Manufacturing of:

- Special measuring inserts according to customer specifications

- Measuring inserts made of special materials

- Resistance thermometers

- Thermocouples

- Assembly of connecting cables

- Parameterization of transmitters

- Express delivery service on request

- Transmitters ex stock e.g. WIKA and ABB

- Manufacturer-independent repair of reciprocators, rotary actuators and drives according to TA-Luft

- Functional testing and damage analysis, incl. preparation of repair cost estimates

- Modifications, e.g. change of Kv-value or spring assemblies according to specifications

- Kv-value determination of the test bench on request

- Pressure and leakage testing up to 300 bar

- Replacement of wear parts such as seal or packing

- Attachment and function test of additional instrumentation such as positioners, limit switches, solenoid valves

- Metallic and lined valves

- Consulting for the design of valves

- Delivery of material certificates 3.1b and 2.2

- Life cycle documentation of the actuators

- Consultation/support for shutdown management

- On-site service or maintenance service in the plant

- Express delivery service for spare parts and valves

Process Analysis Technology

(PAT)

With the aim of achieving a sustainable improvement and optimization of operational processes, we develop customer-specific analysis solutions depending on the measurement task. We support you from conceptual planning to realization, installation and commissioning.

- System planning

- Application and acceptance together with a GC manufacturer

- Completion in our own specialist workshops incl. pre-assembly and FAT (Factory Acceptance Test)

- Commissioning and including SAT (Site Acceptance Test)

- Installation at your site

- System support for all components (also 24/7)

- Individual electronic maintenance plans

- Monitoring of the analyzer system and gas supply

- calibrations

- Digital data acquisition via tablet, with customer access on request

- Extensions to new or existing measuring systems

- Application changes and extensions (e.g. alarms, transmission of additional information to the DCS)

- Carrying out all work in compliance with the provisions of T021/T023 of the BG RCI

- Manufacturer-independent advice, selection and procurement of gas warning devices and accessories

- Operator-oriented, manufacturer-independent equipment training

- Operator-specific qualification training

- Functional and system checks by qualified personnel in accordance with T021/T023

- Rental pool for portable gas detectors and accessories

- Maintenance of gas detection systems, control centers, devices and accessories

- Monitoring of test intervals and implementation

- Digital documentation in compliance with regulations

- Cloud-based approach for measurement data and status information from gas detectors

- Planning of the corresponding measuring points

- Consideration of the conditions and specifications (Ex area, inline, online)

- Manufacturer-independent procurement and installation of components

- Optical measuring method

- Electrochemical sensors

Special features of our electrochemical measuring methods:

- The test or calibration procedures correspond to the requirements of the measuring point.

- The measuring points are checked using qualified test equipment.

- The test is carried out using absolute ozone values.

- A meaningful performance test of the loop and the DCS display.

- Increased process reliability at ozone-free measuring points.

- The measurement is ready for use immediately after the test.

- After the replacement test with air, the run-in time is up to 24 hours.

- No significant additional work is required for on-site testing.

- Advice on optimum process analysis measurement technology for production

- Planning of complete analytical measuring systems

- Consulting/planning and installation of analysis technology for PLT safety and protective equipment

- Generation and reference measurement of defined concentrations for correct function and display

- 2 different humidity trace ranges:

- high: -60°C TP (10 ppm) to +15°C TP (17000 ppm)

- low: -90°C TP (0.1 ppm) to -60°C TP (10 ppm)

- Generated concentrations are set at periodic intervals or alternatively fixed

- Advantage: the test points within the measuring and working range are freely selectable.

- Comparison of actual / target values (calibration) and adjustment if the specified tolerances are exceeded (adjustment)

Manufacturer-independent maintenance, calibration and repair of process analyzers - especially in trace measurement areas

Test equipment management: test equipment fully traceable to national standards

Testing of electrical systems and DGUV V3 tests for stationary and portable electrical equipment

Testing of explosion-protected devices after repair by officially recognized qualified persons in accordance with the Ordinance on Industrial Safety and Health (BetrSichV)

Cleanroom technology & qualification

Cleanrooms in the pharmaceutical industry are subject to strict legal requirements. We offer solutions for your regular cleanroom measurements as well as special measurements during reconstruction measures including cleanroom qualification and documentation.

Examination / qualification of:

- Filter integrity

- Air exchange rates

- Temperature distribution

- Flow profile

- Cleanliness classes

- Room pressure cascades, humidity

- Validation of hot air sterilization

- Microbiological sampling

- Trained specialists with GMP know-how

- Extensive test equipment

- Qualified cleanrooms

- GMP ensured

- Service in time

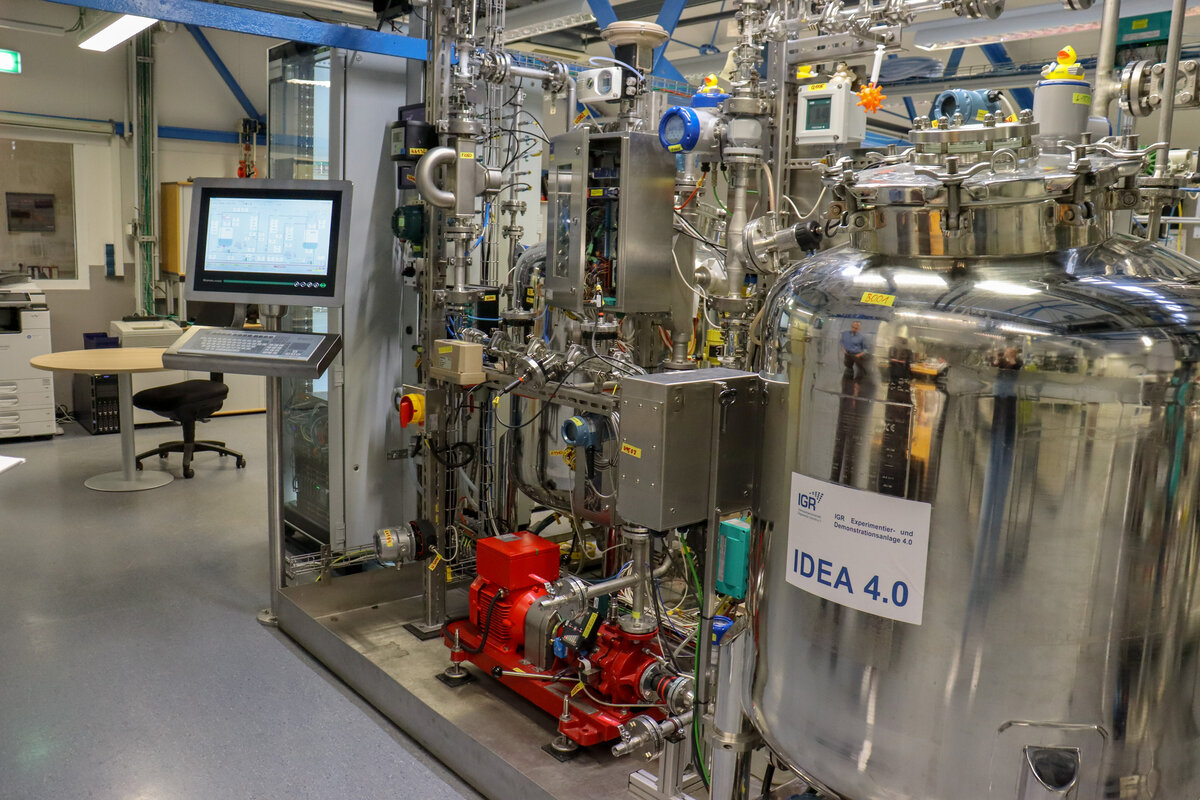

EI&C Testing Laboratory and Digital Product Development

As an independent testing laboratory, we use our many years of know-how to examine equipment and technologies for manufacturers and users. With extensive testing equipment and our pilot plant for digitization, we offer all testing possibilities for the qualification of devices for the process engineering industry.

- Connectivity solutions for process measurement technology to use device information outside of the DCS, e.g. cloud structures.

- Cloud connections, configuration of edge gateways

- Extension of existing sensor technology with wireless additional sensor technology (e.g. Wireless-HART, LoRaWAN, Bluetooth, mobile radio)

- Theoretical training on Foundation Fieldbus, HART, Profibus-DP, -PA, Profinet and Wireless-HART.

- Practical training on a system setup according to your specifications, e.g. on commissioning, replacement of field devices and troubleshooting

- Consulting on system design, fieldbus topology and device selection

- On-site support, e.g. metrological inspection of fieldbus lines and troubleshooting in the plant

- Integration and interoperability investigations on systems, devices and device drivers

- Theoretical training on Foundation Fieldbus, HART, Profibus-DP, -PA, Profinet and Wireless-HART.

- Practical training on a system setup according to your specifications, e.g. on commissioning, replacement of field devices and troubleshooting

- Consulting on system design, fieldbus topology and device selection

- On-site support, e.g. metrological inspection of fieldbus lines and troubleshooting in the plant

- Integration and interoperability investigations on systems, devices and device drivers

Where our EI&C services have made a difference

![[Translate to English:]](/fileadmin/_processed_/5/a/csm_Gerald_Pilotto_c7aced2438.png)

Chief Products & Innovation Officer