- Bilfinger builds a pilot plant for the "reverse coal approach" on behalf of The Lapwing Estate

- The aim of the facility is to produce biochar, renewable electricity and heat

- Novel carbon capture and storage technology extracts carbon from the atmosphere and returns it back into geological reserves for long term storage, sequestering up to 45,000t CO2 emissions stored per hectare

- The project is financially supported by the British government and scientifically monitored by the University of Lincoln and the UK Centre for Ecology and Hydrology

Nottinghamshire, UK. The Lapwing Estate, a British food and farming company, has commissioned Bilfinger to build a pilot plant for their "reverse coal approach". Bilfinger will be responsible for the technical planning, procurement and installation of the plant. Completion of the high-temperature pyrolysis plant in the English county of Nottinghamshire is planned for Quarter 4 2023.

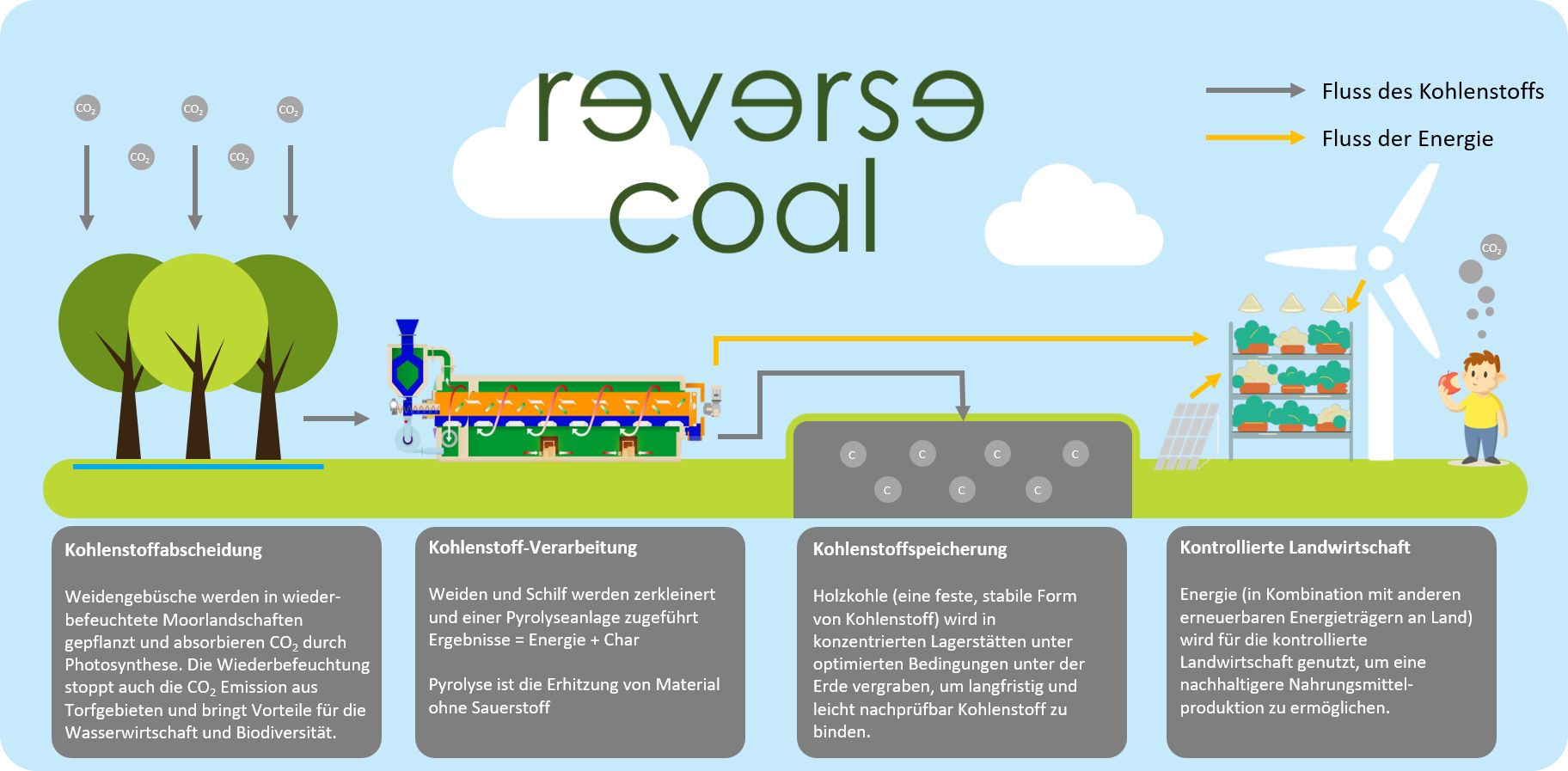

The pilot plant is part of the "reverse coal process" developed by The Lapwing Estate. The aim of this process is to convert CO2 emissions back into solid carbon while producing food with measurable positive environmental and social impact. To do this, peatlands are first rewetted and planted with willow coppice, allowing the peat to slowly rebuild, abating CO2 emissions from the land, and capturing atmospheric CO2 through photosynthesis. Biomass is then rotationally harvested, chipped, and fed in the form of woodchips into the high temperature pyrolysis plant, which breaks down the biomass through thermal decomposition. This produces renewable heat, electricity and biochar. When the biochar is buried underground ("reverse coal"), the raised land remains productive, and the heat and electricity are supplied to controlled environment (indoor) agriculture (CEA) which replaces land transferred to willow growth. This tackles the common criticism of many renewable energy projects, which is that land is lost from food production.

The "reverse coal concept" was successfully verified in a feasibility study. The testing of the concept, which is now planned, is being financially supported by BEIS, the UK Department for Business, Energy and Industrial Strategy within the scope of Phase 2 of the Direct Capture of Air and Other Greenhouse Gases program. Scientific support is being provided by the University of Lincoln and the UK Centre for Ecology and Hydrology.

Bilfinger will be responsible for providing comprehensive technical planning, procurement and installation solutions for the plant. This will include designing the plant layout and technical specifications, detailed engineering, procuring the necessary equipment and components, and carrying out the installation of the plant in accordance with project requirements.

"We are excited to be part of The Lapwing Estate’s innovative CO2 reduction project and delivering the carbon processing plant design, supply and installation," said Sandy Bonner, Executive President for Bilfinger UK. "We see this as a positive opportunity for the future of Bilfinger UK and the environment."

"Reverse coal is a radical and transformative whole systems approach that transitions from traditional organic farming on degraded lowland peat, towards climate resilient, controlled environment agriculture," said James Brown, CEO of The Lapwing Estate. "This approach offers a broad array of interlinked societal, environmental and economic benefits. We are happy to be able to rely on Bilfinger's years of expertise and experience in building technically pioneering facilities for this forward-looking project."

Bilfinger is a long-standing partner to the process industry and supports the sector in its transformation to renewable energies as a solution-partner. The most recent activities Bilfinger is involved in include EPCM services for REEtec’s new rare earths production plant in Norway, the engineering of the HyStock project, an underground hydrogen storage facility in the Netherlands, and the construction of demonstration plant for converting Austrian natural gas infrastructure for hydrogen transport in the so-called HyGrid2 project.