- Stadtwerke Düsseldorf to feed industrial waste heat from Henkel power plant into district heating grid; pioneer work in Germany

- New energy center promotes the city’s sustainability goals and reduces annual CO2 emissions by 6,500 tons

- Bilfinger as comprehensive solution partner responsible for efficient plant engineering from planning to commissioning

Düsseldorf, Germany. The city districts of Garath, Benrath and Holthausen in Düsseldorf are soon to be largely supplied with sustainable district heating. To this end, Stadtwerke Düsseldorf is cooperating with the local industrial and consumer goods company, Henkel: With the help of a new energy center, industrial waste heat from the Henkel power plant will be processed and fed into the city’s district heating grid. To turn this vision into reality, the international industrial services provider Bilfinger has now been contracted as comprehensive solution partner by Stadtwerke Düsseldorf.

At Henkel’s production site in Düsseldorf, a national pioneering project has kicked off construction: Stadtwerke Düsseldorf has commissioned Bilfinger for the implementation of a new energy center that will utilize industrial waste heat from the Henkel power plant to supply district heating to the city’s south. The energetic use of waste heat is highly efficient and sustainable: It enables Stadtwerke Düsseldorf to reduce their need for natural gas and thus save around 6,500 tons of CO2 annually, which results both from the waste heat and from the additional extraction of heat from the combined heat and power generation at Henkel.

“Stadtwerke Düsseldorf’s transformation to efficient and sustainable energy solutions is setting an important example – beyond the borders of Düsseldorf,” says Thomas Schulz, Bilfinger Group CEO. “Our Group Strategy is built on enhancing efficiency and sustainability. We are therefore very pleased to be trusted with the realization of this forward-looking step.”

“Our goal is to consistently expand and further decarbonize the district heating supply in Düsseldorf, as the energy transition in cities is primarily a heating transition. Our cooperation between industry and municipal utilities is quite unique in Germany,” says Julien Mounier, CEO of Stadtwerke Düsseldorf. “We are happy to have Bilfinger as our partner at our side, ensuring the efficient implementation across the entire lifecycle of our project. With Henkel as our cooperation partner and Bilfinger as our solution partner, we are jointly making an important contribution to the heating transition.”

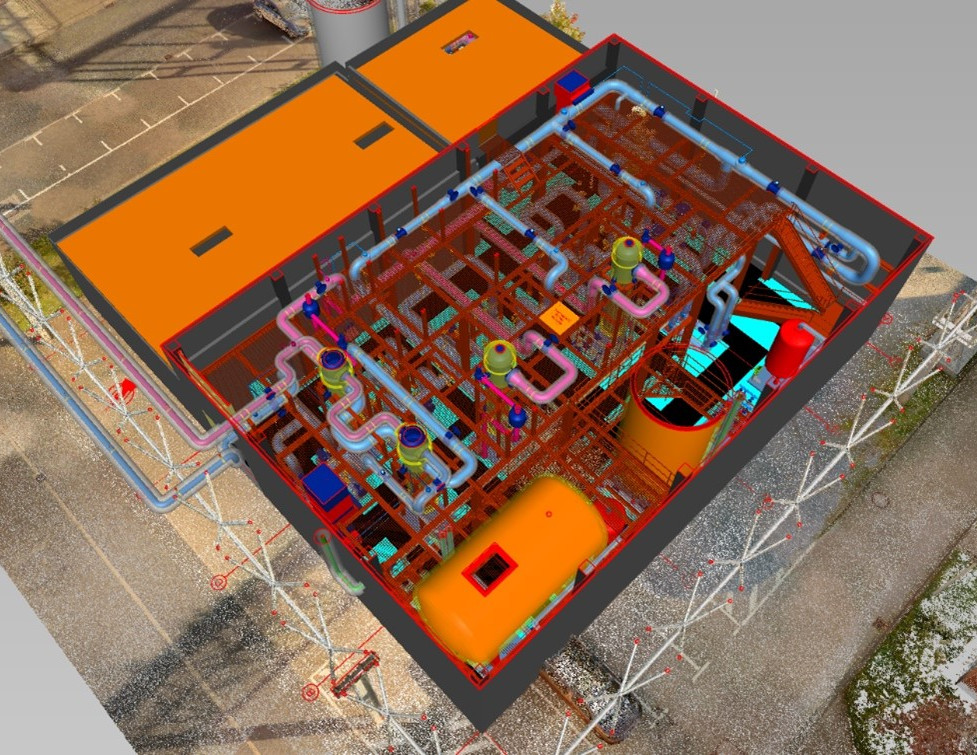

As a leading manufacturer of industrial and consumer goods, Henkel operates a power plant that generates energy for their manufacturing processes. Inside the power plant, waste heat is produced as a side effect of the electricity and steam supply. While these energies usually supply the Holthausen site, a portion of the waste heat which had previously not been used can now be made available to the city of Düsseldorf. With the help of Bilfinger, the new energy center measuring 700 square meters will play a key role in this scenario: Its centerpiece is four heat exchangers that feed the waste heat as well as the heat from combined heat and power generation into the district heating grid.

“We are looking forward to supporting the success of the new energy center with our broad consulting, project management and engineering expertise,” says Michael Martl, President Business Line Life Science at Bilfinger. “Stadtwerke Düsseldorf will benefit from the fact that we can take care of the implementation from a single source across all phases of the project. We will hand over a turnkey plant that will significantly contribute to the city’s path to decarbonization.”

To allow for an efficient implementation, Stadtwerke Düsseldorf is building on the expertise that Bilfinger has gained in numerous projects for customers in the energy sector. As a key solution partner, the industrial services provider is responsible for all project phases of the energy center, from engineering, planning and procurement to commissioning. This includes the construction of the building, including the plant technology, the installation of the connecting piping systems and the automation of the plant. Private households in the neighboring districts of Garath and Benrath will benefit from the result. In the near future, up to 40 percent of the district heating in this area is expected to be supplied from the new energy center.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/a/csm_Market_Pharma_Reference_Siegfried_b872e5bad7.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/0/csm_Bruecke_shutterstock_schmal_Ret_c5e36c8037.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/One_Global_Website/Services/references/oeko_energie_ag_Referenzprojekt.jpg)