Insulation, Scaffolding,

Painting & Rope Access

Do Amazing Things

in the ISP Field

Teamwork is essential to constructing and maintaining large-scale industrial systems. The areas of insulation, scaffolding construction, corrosion protection and rope access offer exciting duties on an expert international team.

Whether constructing an oil platform, renovating a chimney that is hundreds of meters tall, or working on one of our many challenging projects, your work makes a key contribution to Bilfinger, and you will be able to see evidence of your success right away. Bilfinger believes in training and strives to help you prepare for your duties in a targeted way. We value your safety and your ongoing personal and professional development.

Scaffolding for Complex Constructions

You can take on unique challenges in our scaffolding construction area. You will work on large-scale industrial scaffolds that require complex structures to fulfill extremely high requirements for stability and load-bearing capacity. Each scaffolding project is unique and challenging in its own way. Whether these are scaffolds for onshore and offshore industrial systems, highway bridges, tall industrial chimneys or other complex structures, as a highly effective team, we always make even the most unusual customer inquiries possible. To date, the largest continuous scaffold project we have constructed measures 85,000 cubic meters and surrounds a piece of large-scale, open-pit mining equipment.

Corrosion Protection for Long-Term Durability

Corrosion protection helps protect and maintain structures, while also preventing and avoiding damage caused by weather. The unique thing about Bilfinger is the kinds of projects on which you will be asked to work. Your job will involve orchestrating the operation of large-scale industrial systems. These include both onshore systems – such as chemical, pharmaceutical or production systems with giant pipeline structures – as well as offshore equipment such as oil platforms exposed to the effects of wind, weather, and salt water.

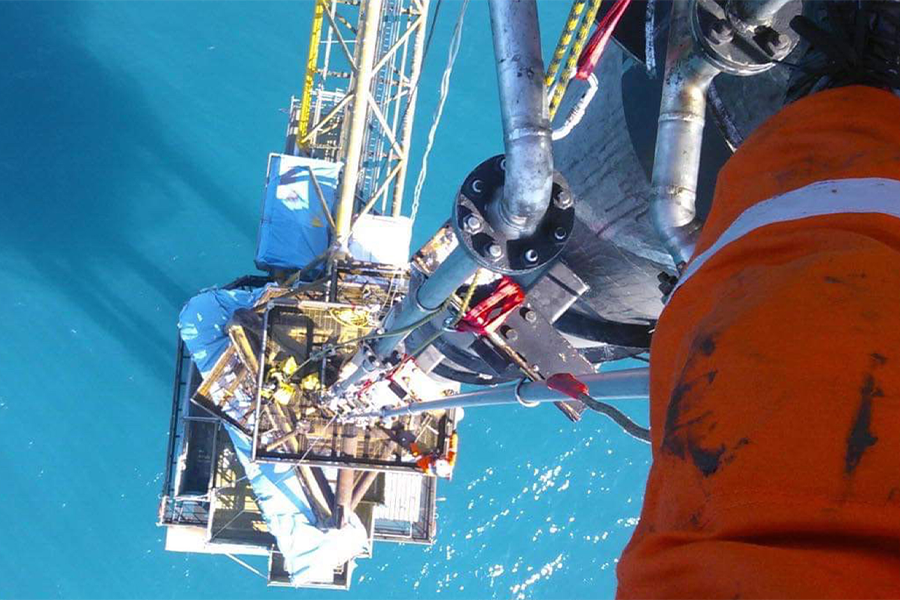

Rope Access Technicians for Special Tasks

As a rope access technician, your skills are in demand to work at great heights or in difficult to access areas. As a leading industrial service provider, Bilfinger offers you a wide range of exciting and diverse work opportunities. Our services by rope access technicians include global inspection, construction and maintenance services on onshore and offshore systems, such as industrial chimneys or drilling platforms.

Your safety and continued development are very important to us. Because of this, we offer you outstanding training and continued education services.

Always Open to Innovative Work Methods

Work easier with an exoskeleton

The areas of insulation, scaffolding construction, corrosion protection and rope access involve performing difficult physical work. We are always looking for innovative work methods and equipment to relieve our employees and help them perform their duties easier. An example includes the exoskeleton developed through a pilot project in the Netherlands. The exoskeleton is a compact, lightweight mechanical support structure that supports an employee's arm and shoulder as they work. Test results so far speak for themselves. Using the exoskeleton allows the work to be completed almost effortlessly. Arm strength is increased significantly, and fatigue is greatly reduced. This helps to protect employee health over the long term.

Just One of Our Many ISP Projects

A valuable contribution to climate protection

Heat loss from equipment is not only a factor in terms of cost but an environmental factor as well. To identify weak points and unused potential in insulation and in non-insulated components, Bilfinger uses the TIPCHECK process (Technical Insulation Performance Check). This process is used not only to inspect existing insulation for defects and damage, but for any “hot spots” as well. These are non-insulated components, such as flanges, fittings or wall brackets where heat and, therefore, energy are lost. To do so, we use equipment like thermal imaging cameras and contact thermometers to better detect heat loss from systems or specific system parts. Then, measures are taken to improve insulation based on the testing results. Subsequent measurements of values from completed projects confirm the positive effects of this process. We were able to reduce CO2 emissions from a Swiss system, for instance, by six tons per year. The TIPCHECK process makes an effective contribution to climate protection.

Ready for Inspiring

Work on Interesting

Projects?

We are looking for applicants in the

following areas, among others:

- Scaffolding constructor

- Industrial insulator

- Rope access

- Painter

- Corrosion protection

- Fire protection

- Sound insulation

- Painters

- Mechanical engineer

- Specialty cleaner

Breathtaking Moments

Personal Insights Into Our

ISP Field and Rope Access