Mechanical

Bilfinger supports the energy and process industry by delivering comprehensive mechanical solutions in the following specialist areas:

- Process and detail engineering (mechanical)

- Production and installation of vessels, tanks and apparatuses

- Piping construction

- Steel structures

- Plant installation

- Rotating equipment

- Fittings service

- Quality assurance and quality control

With our in-house workshops, we provide our customers with customized solutions, guaranteeing the highest level of quality and safety. Our team of highly-competent mechanical professionals ensure that the power and process industries are able to increase plant efficiency.

Process and detail engineering (mechanical)

Bilfinger has a strict focus on its customers and offers innovative engineering solutions in all areas of process plant engineering.

We offer the following services:

- Pre-engineering

- Basic and detailed design

- Consulting

- Monitoring

- Project management

We work with the most modern design and calculation programs and have our finger on the pulse of the most recent developments in the industry.

Production and installation of

vessels, tanks and apparatuses

Bilfinger looks back on decades of experience in the manufacturing field. Flexible, reliable and with a clear focus on the customer, we are a competent and efficient partner in international plant engineering. With our extensively equipped workshops and flexible working hours, we can ensure our customers receive customized products of the highest quality.

Prefabrication includes the manufacture of piping spools and assemblies for complete industrial and power plants throughout the world.

We manufacture heat accumulators, tanks, apparatus and vessels such as filter separators, heat exchangers, process vessels, scrapper traps, storage vessels and general pressure vessels.

Bilfinger has decades of experience in the field of welding. Our team of welding technology specialists works with the following welding methods:

- Manual arc welding

- Metal active gas/metal inert gas welding

- Tungsten inert gas welding

- Gas fusion welding

We ensure compliance with both national and international standards and regulations.

Piping construction

We offer top-quality individual piping solutions and always in accordance with the highest technological standards. Through the extensive prefabrication of piping and components in our own workshops, Bilfinger ensures efficient workflows and a high level of safety and quality.

We manufacture and assemble high-quality piping systems in all common nominal sizes and made from a range of materials:

- Stainless steel

- Hastelloy

- Steel / PTFE

- Enamel

- Plastic

- PVDF

- Glass

Steel structures

We produce steel and specialized structures of any kind, including stages, platforms, stairs, walkways, pipe bridges, piping supports or the manufacturing of skids. Bilfinger is the partner you need when it comes to aluminum and steel structures. We support our customers not only in design, but also in the preparation of structural analysis (including drawings) and parts lists as well as in the modular planning of skids and piping bridges.

Our manufacturing and approval processes are based on DIN EN 1090-2 with design classes EXC 3 and EXC 4.

Plant installation

The professional installation of plants, equipment, machines and systems is a decisive factor in the industry. With our experts, we work to ensure smooth commissioning and trouble-free operation of your plant.

We are specialized in the creation of what are known as Mechanical Execution Concepts which enable us to apply our many years of expertise in a time and cost-efficient manner for our customers at an early planning stage.

We have decades of experience in various industries, including the chemical and pharmaceutical industry, power plant and mechanical engineering as well as in the new industries associated with the energy transition, such as battery production, hydrogen and CCUS.

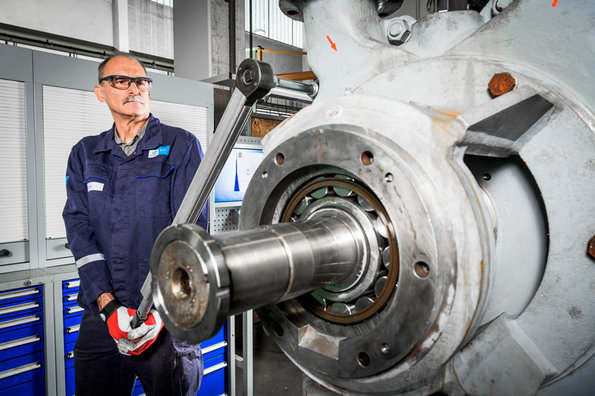

Services for rotating equipment

From manufacturer-independent consulting and maintenance to ongoing optimization and repair, Bilfinger offers comprehensive services throughout the entire service life of rotating equipment. We monitor ongoing operations and guarantee process safety and maximum reliability. This service package is complemented by a large rental pool that includes 20,000 pieces of equipment consisting of pumps, drive motors and frequency converters.

High availability, time efficiency, cost savings

Pumps, reciprocating compressors and turbomachinery are at the heart of many production plants. They convey liquid or gaseous raw materials as well as process industry end products and ensure they are in constant motion. Because they generally operate around the clock, they are significantly responsible for the availability and economic efficiency of process industry plants.

Bilfinger Rotating Assessment

With the Bilfinger Rotating Assessment (BRA), we help our customers develop risk-based and sustainable maintenance for their rotating equipment. BRA is a tool for identifying optimization potential and recommending measures to reduce costs and improve availability.

- Status monitoring online and offline using vibration measurements

- Oil sampling, analysis and evaluation

- Maintenance and cleaning of lubricating oil and hydraulic systems

- Troubleshooting and RCA (root cause analysis)

- Planning and execution of general overhauls as a turnkey project including mechanical, scaffolding, electrical, automation and insulation services

- Alignment and balancing of compressor and turbine trains

- Heavy assembly of all components

- Management and repair of critical spare parts

Bilfinger employs a large number of highly-skilled workers with a variety of key qualifications, Including supervisors, project managers, planners, machine and turbine fitters.

- Consulting:

Experienced technicians and engineers support customers as early as the planning phase and work to optimize availability as well as improve the energy efficiency of rotating machines - Maintenance:

Predictive maintenance using vibration measurements to avoid unexpected downtime and reduce repair costs - Workshop service:

OEM-independent full service with detailed damage analysis and solution-oriented repair - Rental equipment pool:

Reducing customers’ investment costs by renting pumps, electric motors or frequency converters; uncomplicated and fast replacement supply in case of damage of the rented equipment

We supply critical spare parts for rotating equipment with short delivery times and guaranteed quality to minimize downtime. Exceeding the OEM standards, we support the fulfillment of service expectations, manufacture spare parts, perform 3D scans and re-engineering. These can be, for example, turbine blades, vanes, disks, impellers, stators/diaphragms, nozzles and rotors.

Valve service

Our qualified specialists carry out manufacturer-independent services on valves and plant components of all sizes in close coordination with the responsible inspection authority. We would be happy to provide you with advice regarding plant shutdowns.

- Maintenance:

Repair of all makes and nominal sizes in our workshops as well as on site in your plants - Workshop service:

OEM-independent complete services with detailed damage analysis and repair in accordance with the manufacturer’s specifications, full documentation including acceptance by the responsible inspection authority - Manufacturing of spare parts:

OEM-independent procurement and in-house production of spare parts in accordance with drawings or state-of-the-art 3D measurement; uncomplicated and fast supply of critical spare parts in the event of damage

Quality assurance and quality control

Bilfinger conducts it services in accordance with international regulations and approves them. We rely on strict quality assurance (QA) and quality control (QC) throughout the production process. This ensures the achievement of the desired product quality.

Benefits for our customers

- Plant construction from a single source, from engineering to implementation and commissioning

- Avoiding unnecessary interfaces and costs

- Increased asset availability through status-based maintenance and optimization measures

- Short-term and flexible access to a large number of specialist tools and human resources with a range of qualifications

- Cost-efficient and sustainable service solutions throughout the entire service life of the rotating machine

- Sustainable repair by machining the parts on site in your plants as well as overhauling plant components if technically possible and necessary

Where our mechanical services have made a difference

Director Mechanical Services