- Collaboration with long-term customer on multiple projects to future-proof the natural gas grid in the Netherlands

- Flexible deployment of more than 100 highly qualified engineers and consultants during peak periods

- Recently signed order on services for new hydrogen network in the Southwest Netherlands

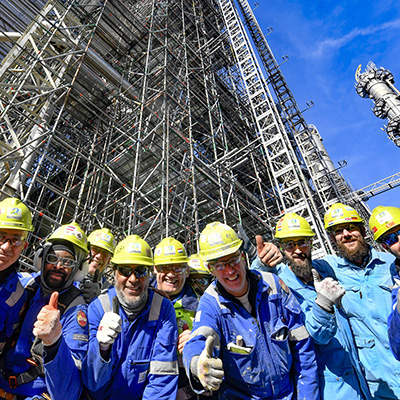

Groningen, The Netherlands - Bilfinger has been awarded a major 10-year framework contract for comprehensive engineering services by Dutch energy network operator Gasunie. The scope of the agreement covers a wide range of projects related to the energy transition, including engineering services for new energy initiatives such as hydrogen transport and CO2 transport and storage. It also includes the modification and expansion of the existing natural gas network infrastructure to support the transition to more sustainable alternatives such as hydrogen and biogas.

In the context of the energy transition, Gasunie is investing substantially in the modernization of the national natural gas transport network in order to meet future energy demand in a sustainable way. A major focus is the development of hydrogen projects, with several initiatives already underway. Bilfinger, through its Engineering BeNe Business Unit, will support Gasunie with comprehensive engineering services, including feasibility studies, conceptual design and detailed engineering.

"We are proud that our long-standing customer Gasunie is relying on our engineering expertise in this significant energy transition initiative. Hydrogen plays a crucial role in this transformation, and by combining our expertise in hydrogen technology with our many years of experience in the gas sector, we are able to offer our customer added value,” says Bilfinger Group CEO Thomas Schulz.

The first projects under the framework agreement have already commenced, with Bilfinger recently signing a contract with Hynetwork Services, a wholly owned subsidiary of Gasunie, for detailed engineering services on the so-called "Hydrogen Network Southwest Netherlands". This network is being realized in Zeeland and West Brabant and aims to supply the industry in this region with green hydrogen and connect it to the other industrial clusters and hydrogen infrastructure, for example to Gasunie’s hydrogen storage facility HyStock, for which Bilfinger also provided engineering support. The Hydrogen Network Southwest Netherlands will be part of a national hydrogen network with completion targeted for 2030.

Bilfinger offers services along the entire hydrogen value chain: from production through storage and delivery to the use of hydrogen. The services include consulting and engineering, subsequent plant construction and EPC (engineering-procurement-construction), and all maintenance and services. Most recent orders include EPCm (engineering-procurement-construction management) services for a hydrogen storage pilot project with Uniper in Northern Germany.

![[Translate to English:]](/fileadmin/_processed_/3/4/csm_Hoppe_ce252ecc80.jpg)

![[Translate to English:]](/fileadmin/_processed_/f/2/csm_Andreas_Hilpert2_4ad2ba8bdf.jpg)

![[Translate to English:]](/fileadmin/_processed_/3/c/csm_Karsten_Knipper_b236b95ef1.jpg)

![[Translate to English:]](/fileadmin/_processed_/9/7/csm_maurice-heine.1024x1024_19dc3876d7.jpg)

![[Translate to English:]](/fileadmin/_processed_/5/b/csm_Ingo_Wurzel_3611_Zuschnitt_b772993d40.jpg)

![[Translate to English:]](/fileadmin/_processed_/3/d/csm_News_Pressekontakt_KatharinaSchoenebeck_b48271ab3e.png)