Nuclear Power

Partner for the nuclear industry

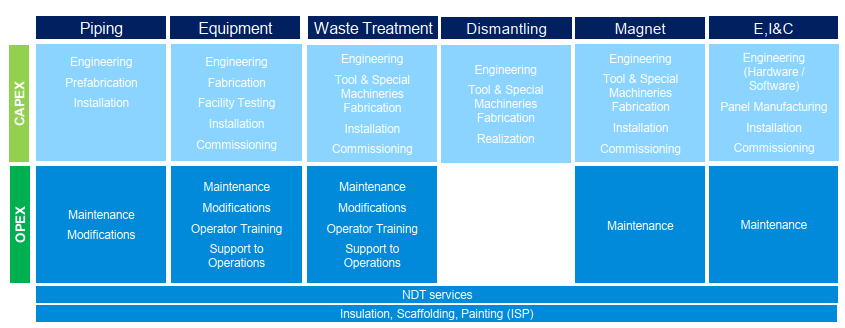

Bilfinger has successfully supported and advised customers from the nuclear industry for decades. Our products and services support the entire life cycle of nuclear facilities, components and systems. We provide everything from concept design and engineering to manufacturing, construction, commissioning, maintenance, modernization and dismantling and treatment of radioactive waste. We also develop and construct special magnets for nuclear fusion facilities. We deliver our services across Europe, Asia, the Middle East and North and South America.

From Engineering to Execution from one source

Thanks to vertical integration, Bilfinger supports customers all the way from the first planning and engineering phases to manufacturing, assembly, installation and commissioning of complete facilities, components and systems. During your operations, we can provide support staff, training, maintenance and modification services. We also help customers with their decommissioning and dismantling projects from start to finish.

Bilfinger is active in all Nuclear Segments

For more than 60 years, Bilfinger has supported all market segments of the nuclear industry. This includes new builds, maintenance & plant modernization, deactivation and decommissioning, waste management and nuclear fusion. For the Small Modular Reactor market, we collaborate with technology owners to support the transition from concept to design to project. In Germany and in the UK, Bilfinger also supports the national defense sectors, mainly with decommissioning and research projects.

High-class manufacturing capacities in Europe

With four nuclear workshops in Germany and in the UK, Bilfinger has unique industrial assets for its own projects and for external customers in need of manufacturing and assembly support.

Our shop in Dortmund (Germany) has 24,000m2 of space dedicated to piping prefabrication with unique induction bending capabilities (up to DN870). We have two shops dedicated to equipment and magnet manufacturing and assembly. We also have a dedicated workshop in the UK for electrical panels.

Meeting market and customers’ requirements around the world

Bilfinger is certified to work under most codes and standards in force in the nuclear sector in Europe and globally.

ESPN, RCC (M&E), ASME and KTA are just a few examples.

Our Nuclear Products & Services

With more than 20 years of experience in the field and a dedicated legal entity based in France, we are specialised in Layout Engineering and General Installation studies enabling the complete 3D modelling of industrial plants, the associated mechanical and structural calculations and the delivery of manufacturing plans. We also support customers with the validation of their industrial design both on mechanical and structural aspects.

Bilfinger benefits from extensive in-house prefabrication capabilities for nuclear and conventional piping both in Germany and in the UK with unique induction bending capabilities. We support customers from engineering (basic, detailed and execution design) up to installation and commissioning of all pipes within a nuclear power plant (Nuclear and Conventional Islands) and all types of nuclear facilities. We also have expertise with the most advanced welding technologies (orbital welding, narrow gap welding) and can provide expert welders for our own project as well as for external projects.

Bilfinger supplies diverse components and equipment for nuclear power plants of all reactor types worldwide. The services provided include conceptual design, design review documentation, material sourcing, manufacturing, assembly and documentation, as well as on-site installation, testing and commissioning.

We provide components and equipment for all type of projects, from new builds to plant upgrades and retrofits and planned component exchanges.

Bilfinger benefits from extensive know-how in the treatment and conditioning of liquid and solid radioactive waste as well as residual materials.

We develop, design, install and commission complete facilities on a turnkey basis to treat radwaste coming from both operating plants and dismantling projects. We also support our customers throughout their plants’ life cycle by providing operating personnel, training sessions for our customers’ own staff and maintenance services.

Thanks to our knowledge of a wide variety of treatment methods, we can select the most suitable solution to always maximize the reduction of the waste volume, condition it in accordance with the storage conditions and pack it for intermediate and final storage.

Bilfinger has supported customers in successfully completing their dismantling projects for decades. Our extensive expertise, especially in the dismantling of large components, allows us to develop best-spoke solutions for our customers.

Our services range from feasibility studies, approval planning and design and manufacturing of specific equipment, to project execution and post-operation support. We assume responsibility for both individual tasks and the complete dismantling of nuclear facilities.

With a strong pedigree in automation and digital technology and comprehensive knowledge of industry processes, regulations and standards, we offer solutions that improve safety, reliability, plant performance and optimisation.

We are a market leader in automation consultancy, design, development, installation and commissioning. With extensive experience in highly regulated environments combined with a strong focus on compliance and safety, we develop solutions that add value for our customers.

Our highly skilled engineers can develop and integrate solutions tailored to meet specific project needs. Our independent status means that we can recommend the best technology to meet customers' unique requirements, helping deliver optimum performance of assets.

Magnets and magnet systems play a key role in nuclear fusion. They establish the conditions under which fusion can take place.

In close cooperation with major research institutions, we have developed multiple superconducting magnet systems, test facilities and cryostats. We have recent experience building prototypes and developing customized solutions.

Where our services make a difference in the nuclear industry

![[Translate to English:]](/fileadmin/_processed_/9/7/csm_maurice-heine.1024x1024_19dc3876d7.jpg)

Head of Sales Nuclear

![[Translate to English:]](/fileadmin/_processed_/9/7/csm_maurice-heine.1024x1024_7683318fe1.jpg)