Dosing and mixing technology

Bilfinger plans, manufactures and supplies complete process engineering systems under the product name dmt, from engineering to commissioning and training of customer personnel. The systems are mainly produced for the gas, chemical, food and beverage industries.

We produce:

- Dosing pumps

- dosing systems

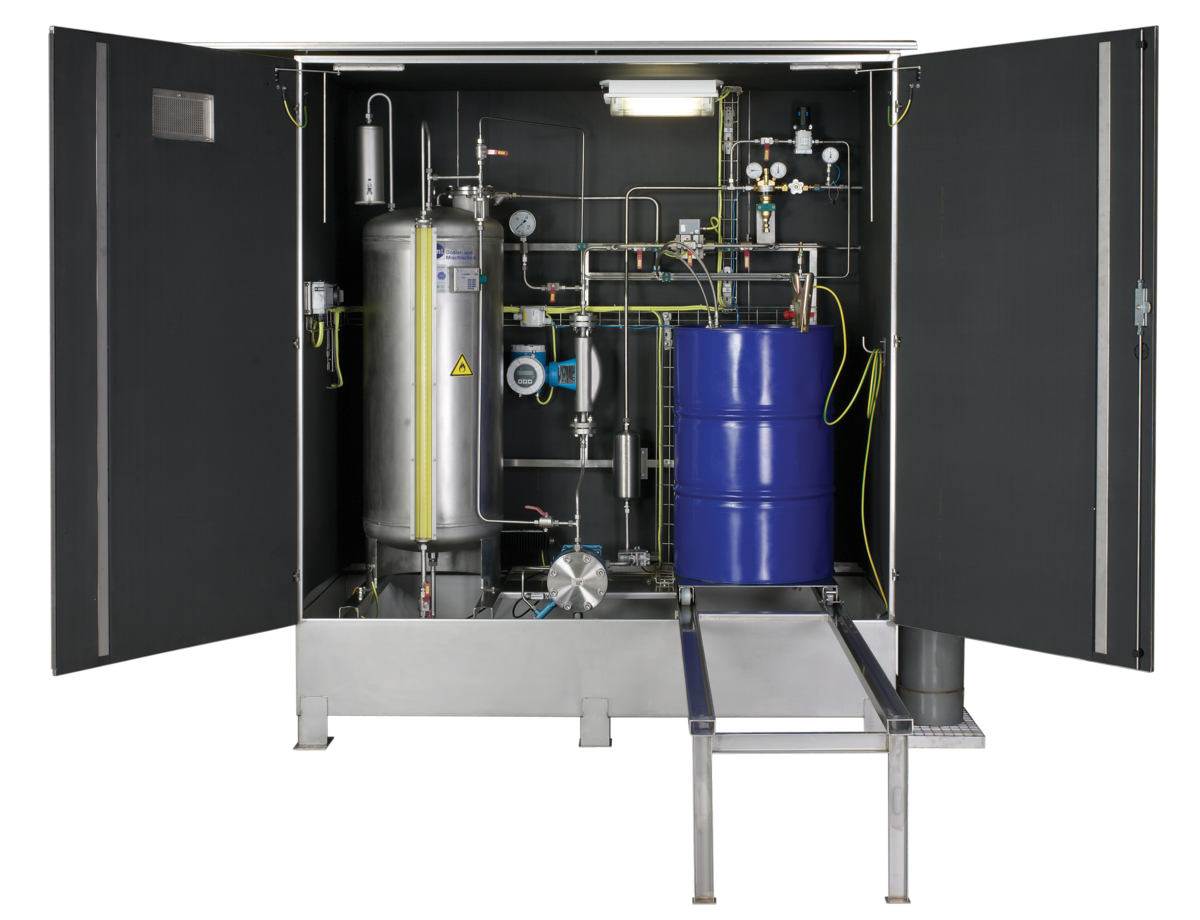

- Methanol and glycol dosing systems

- Gas odorizing systems

- Dynamic loop mixers

- Static loop mixers

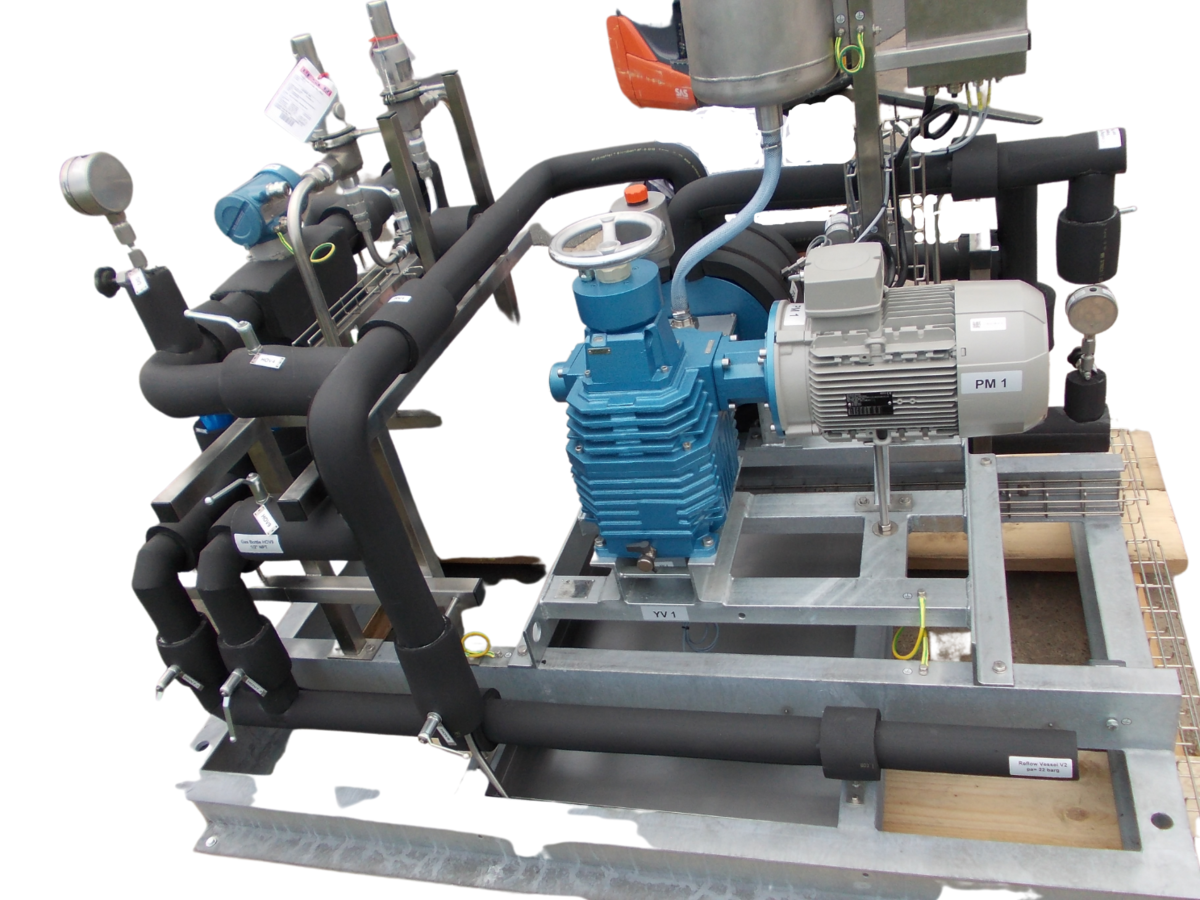

Bilfinger has been planning, building and supplying complete dosing systems for liquid media or liquefied gases for many decades. We respond to your individual requirements and develop solutions for a wide range of industrial sectors, such as

- Glycol/methanol dosing systems for the natural gas industry

- Velcorin® dosing units for the cold sterilization of soft drinks in the beverage industry

Our dosing systems work up to a pressure of 300 bar and dosing volumes of up to 350 l/h. Our spectrum ranges from the production of individual single units to series production.

We are one of the leading suppliers of odorizing systems for a wide variety of gases such as natural gas, biogas, hydrogen and liquid gas in Germany and Europe. Our odorizing systems ensure that the exact specified quantity of odorant is continuously supplied in proportion to the gas flow.

Thanks to our experience and based on a modular system design, we can offer a wide range of odorizing systems that precisely meet the individual requirements of our customers in terms of model and technology. All tank sizes and dosing pumps are compatible and therefore allow maximum flexibility for adapting the overall system to your spatial requirements.

The dynamic loop mixer, designed and built by Bilfinger, is a process engineering system for mixing a certain number of product components into a homogeneous product. The closed design ensures maximum microbiological safety.

Dynamic loop mixers are suitable for mixing tasks in the low to high viscosity range and use an internal screw conveyor with variable speed. Static loop mixers are used in the low-viscosity range and require an external conveying device.

The mixers can be supplied with a heating/cooling jacket and can be cleaned up to 140°C using the CIP process. The main areas of application are the food, chemical and cosmetics industries.

Bilfinger offers technical solutions for various industrial sectors according to customer requirements. High pressures? Small quantities? Aggressive liquids?

Whether process systems or individual components (such as high-pressure metering pumps): We implement your process engineering concepts!

- Basic and detail engineering

- Manufacturing

- Assembly

- Commissioning

- Maintenance and service

- Spare parts delivery

- Training courses

Mayonnaise production plant, analysis container for deodorizing natural gas, modular container plant for crude oil processing, process plant for filling N2O cartridges, process pumps for 1 - 5,000 l/h up to 1,000 bar

![[Translate to English:]](/fileadmin/Germany/Ueber_Uns/Bilfinger_in_Deutschland/Bilfinger_Engineering___Maintenance/BEM_LE_Page/Kontakte/400_x_400_Zekim_Bajrami.jpg)

+49 64089003-53