Service for Turbomachinery,

Generators and Electrical Machinery

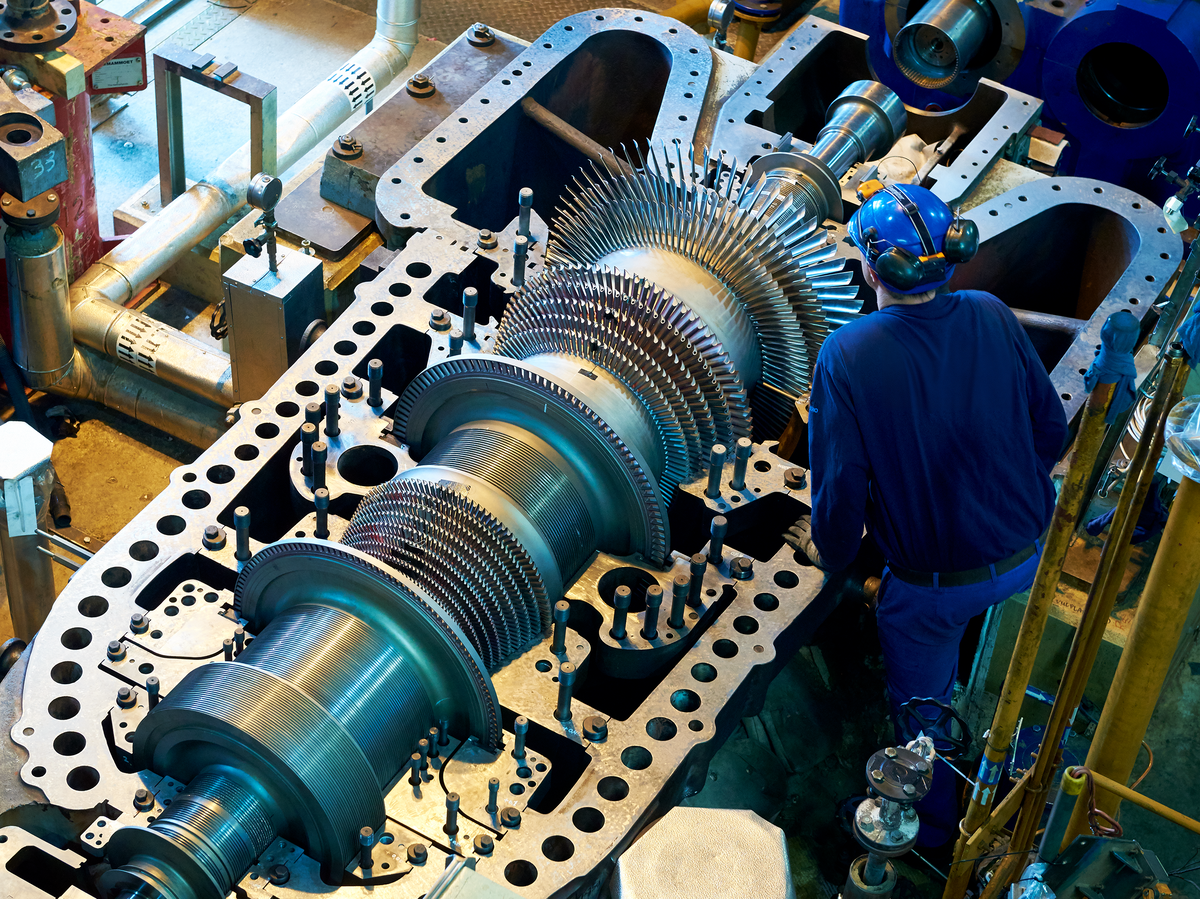

As a specialist in rotating equipment, Bilfinger Rotating Equipment Germany GmbH offers manufacturer-independent service for turbomachinery, generators and electric motors. Our customers benefit from rapid response times, short repair cycles and consistently high availability – throughout Europe and beyond.

Maintenance

Reliable maintenance of turbomachinery, generators, and electric motors

Our maintenance services ensure maximum availability and extended life cycles for your systems. We offer professional maintenance and repair services for steam turbines, compressors, turbogenerators, hydroelectric generators, single-phase generators, high-voltage motors, DC machines, and other rotating machines such as gearboxes, pumps, and fans.

- Regular inspections and repairs

- Spare parts service for all machine types

- Maintenance contracts with individually tailored intervals

- Field service by mobile assembly teams

- Advice on maintenance strategy

- Project support for construction sites and overhauls

Engineering & Modernisierung

Technical engineering and retrofitting for rotating machines

We support you in the new installation, modernization, and optimization of your systems—from reverse engineering and automation to the manufacture of individual components. Our expertise covers turbomachinery, generators, motors, and drive units in a wide range of performance classes.

- Project planning, installation, and commissioning of new and used systems

- Reverse engineering for components that are no longer available

- Retrofit and modernization of existing systems

- Upgrades to increase performance and improve efficiency

- Automation and systems engineering

- In-house component manufacturing and manufacturing with our partner network

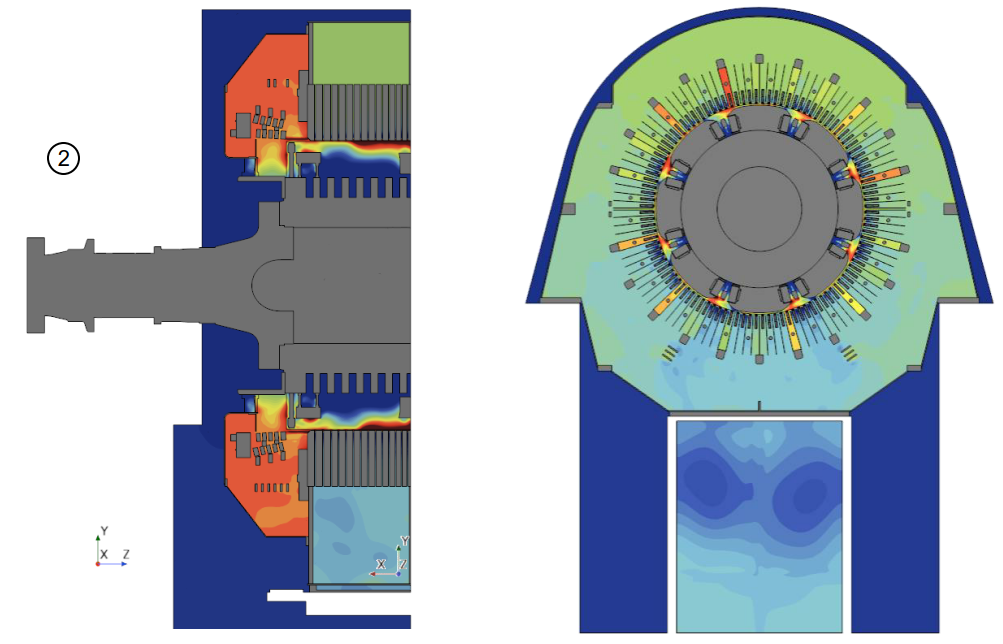

Diagnose & Analyse

Precise condition assessment of machines and systems

We use state-of-the-art methods to analyze the condition of your turbomachinery, generators, and electric motors—for early fault detection, targeted measures, and optimized system performance. Our diagnostic methods are also suitable for complex machines such as high-voltage motors, blower fans, and DC machines.

- Troubleshooting in the event of malfunctions and failures

- Simulation using the finite element method (FEM)

- Computational fluid dynamics (CFD) for flow and heat analysis

- Performance evaluation and efficiency analyses

Successful Projects in the Field of Turbomachinery, Generators and Electric Motors

Manufacturer-Independent Service

We service all machine types and performance classes – flexibly, efficiently, and independently of the manufacturer.

In-House Workshops

Our specialized workshops for turbo and electric machines enable maximum adherence to delivery dates and customized solutions.

Quick Inspections and Repairs

We reduce downtime through well-established processes – for the reliable operation of turbomachinery and generators.

Mobile Installation Teams

Our teams are available immediately – throughout Europe and equipped for any on-site assignment.

Guaranteed Supply Security

A strong partner network ensures the rapid availability of spare parts and components for rotating machines.

Long-Term Customer Relationships

Our customers have relied on quality, reliability, and personal service for many years.

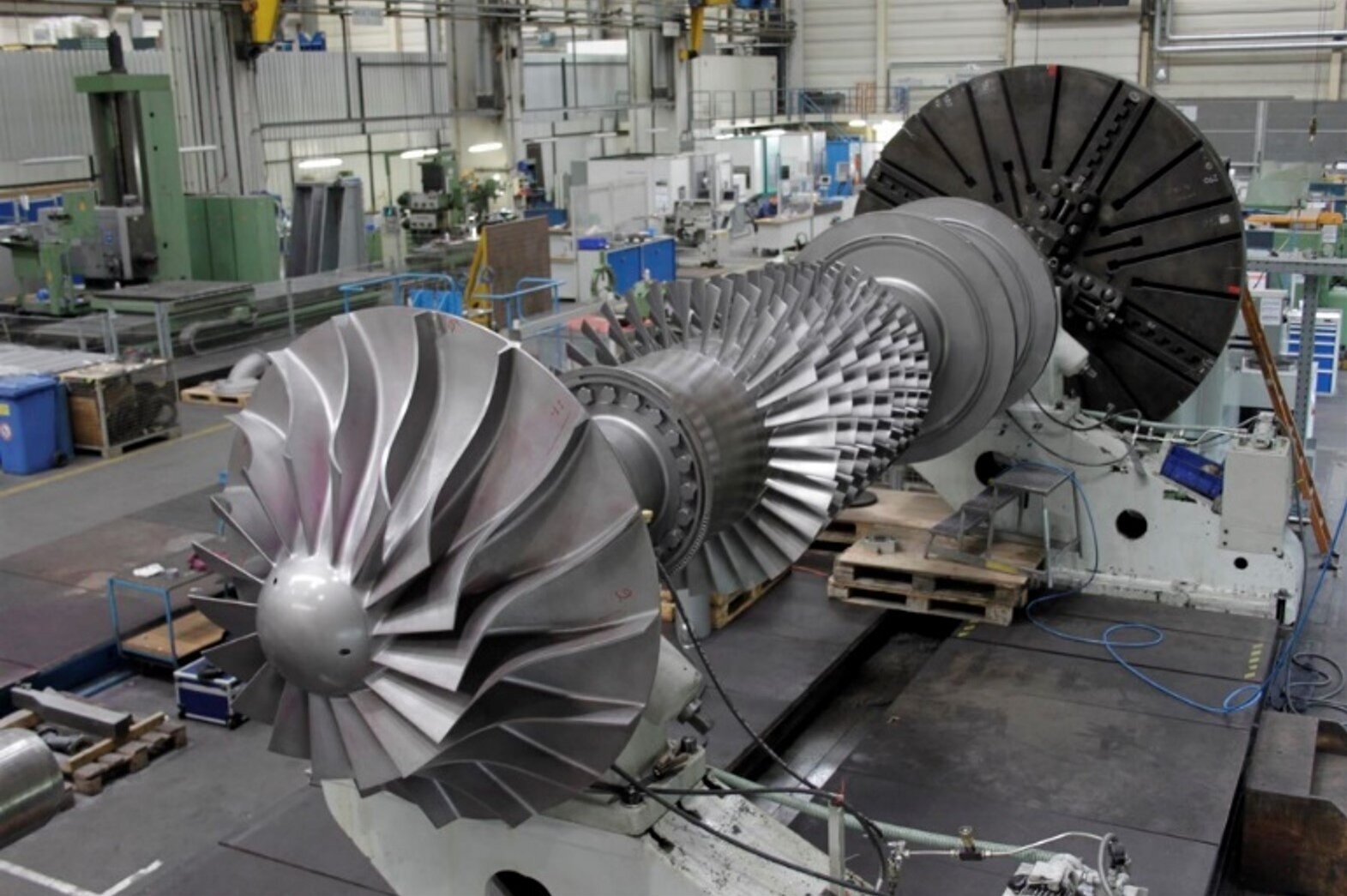

Essen & Karlsruhe – Turbomachinery

Locations: Essen (main location, production area 7700m²), Karlsruhe

Focus: Turbomachinery

- Steam turbines, turbo compressors, gearboxes, pumps, blowers, controls, automation, auxiliary systems, component manufacturing

Umfassende Expertise und Erfahrung in der Konstruktion, Installation und Wartung von Turbomaschinen.

- Inspektionen & Diagnostik

- MRO (Wartung, Reparatur, Überholung)

- Komplettwerkstatt- & Felddienstleistungen

- Reverse Engineering & Upgrades

- Numerische Simulationen (CFD, FEM, Rotordynamik)

- Rotor- & Statorüberholung und Erneuerung

- Hochgeschwindigkeits- & Niedriggeschwindigkeitswuchtung (Werkstatt und vor Ort)

- (De-)Kommissionierung

- Fehlersuche und Ursachenanalyse

Integrierte Lösungen für alle Komponenten des Turbokompressor-Zuges.

- Inspektionen & Diagnostik

- MRO (Wartung, Reparatur, Überholung)

- Modifikationen

- Ersatzteile (Reverse Engineering)

- Numerische Simulationen (CFD, FEM)

- (De-)Kommissionierung

- Fehlersuche und Ursachenanalyse

- Beschichtungen

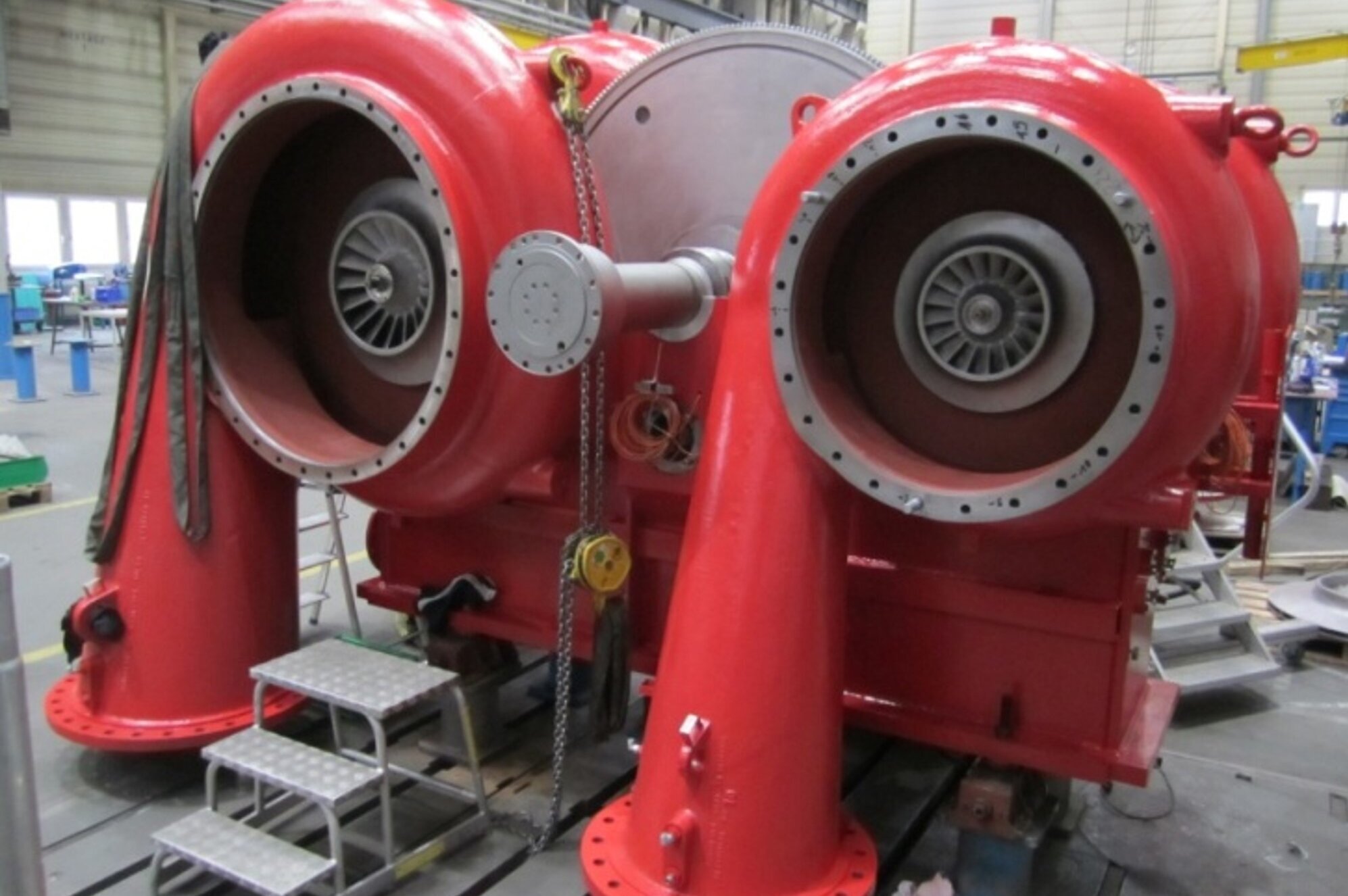

Für Druckluft & Stickstoff inkl. Wartungsservice aus einer Hand.

Service an:

- Axial- und Radialturboverdichter

- Einstufige & mehrstufige Turboverdichter

- Teilfugmaschinen und Topfverdichter

- Einwellen- und Getriebeverdichter

- Sauerstoffverdichter

- Gebläse

Leistungsportfolio:

- Lieferung, Montage und Inbetriebsetzung

- 100 % ölfreie Druckluft zertifiziert nach ISO8573-1, Klasse 0

- Einhaltung globaler Industriestandards wie ISO9001 und API672

- Hocheffizienzorientierte Komponenten

- Wartungsservice über die gesamte Lebensdauer hinweg

- Ersatzteile

- Optionaler Mastercontroller zur Effizienzoptimierung der Drucklufterzeugung

Für sowohl Turbinen- als auch Kompressorensteuerungen liefern, installieren und kommissionieren wir DCS- und PLC-basierte Regler, Sequenzierungs- und Überwachungslösungen.

- Maßgeschneiderte Steuerungspakete

- Individueller Komponentenersatz

- Design und Implementierung von Schnittstellen

- Transparente Programmierung

- Integrierte Steuerungslösungen für Turbinengeneratoren und Turbinen-/motorgetriebene Kompressorzüge

- Steuerungs- und Betätigungssystem-Nachrüstungen

- Modifikation von Steuerungssystemen

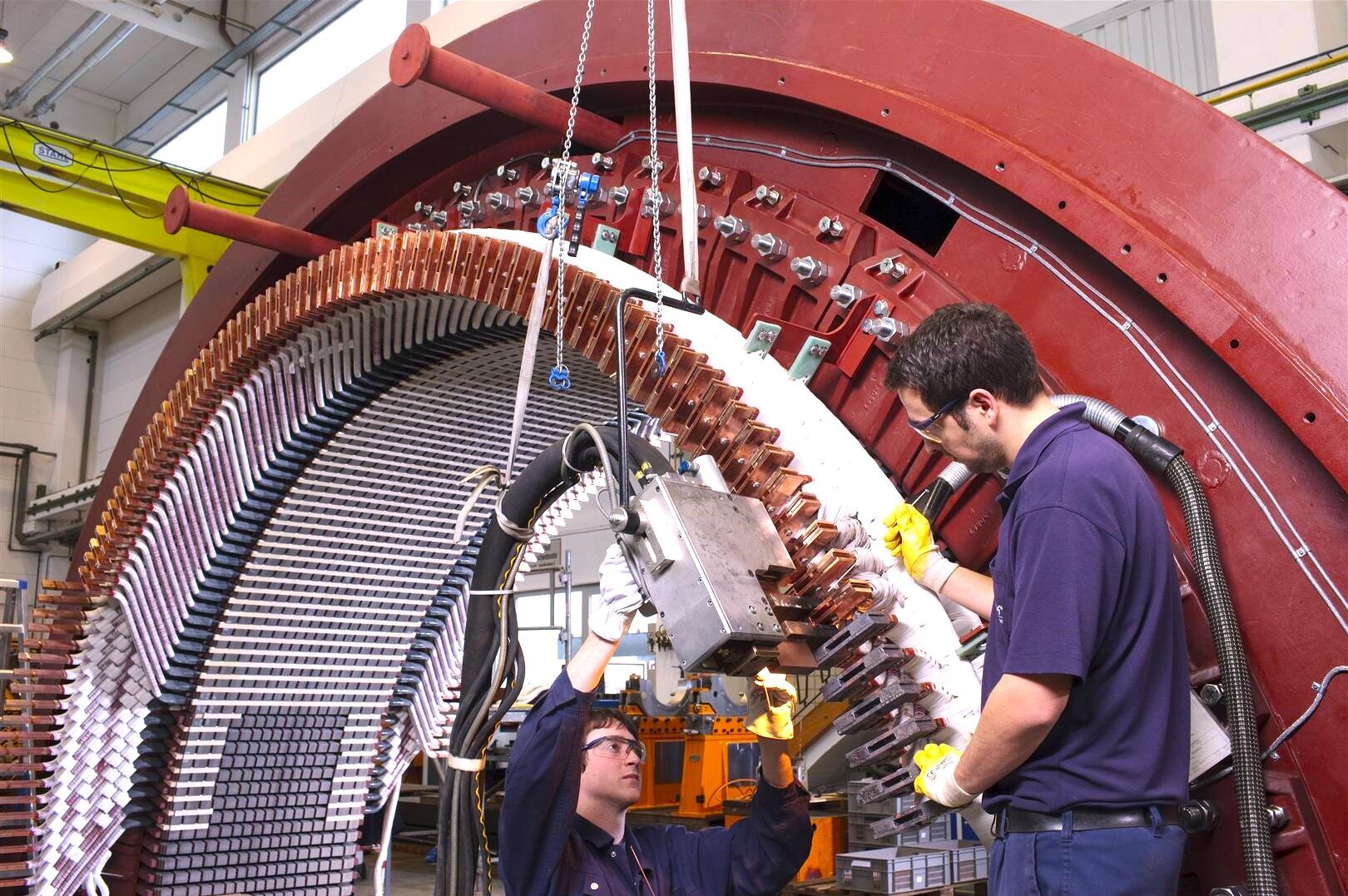

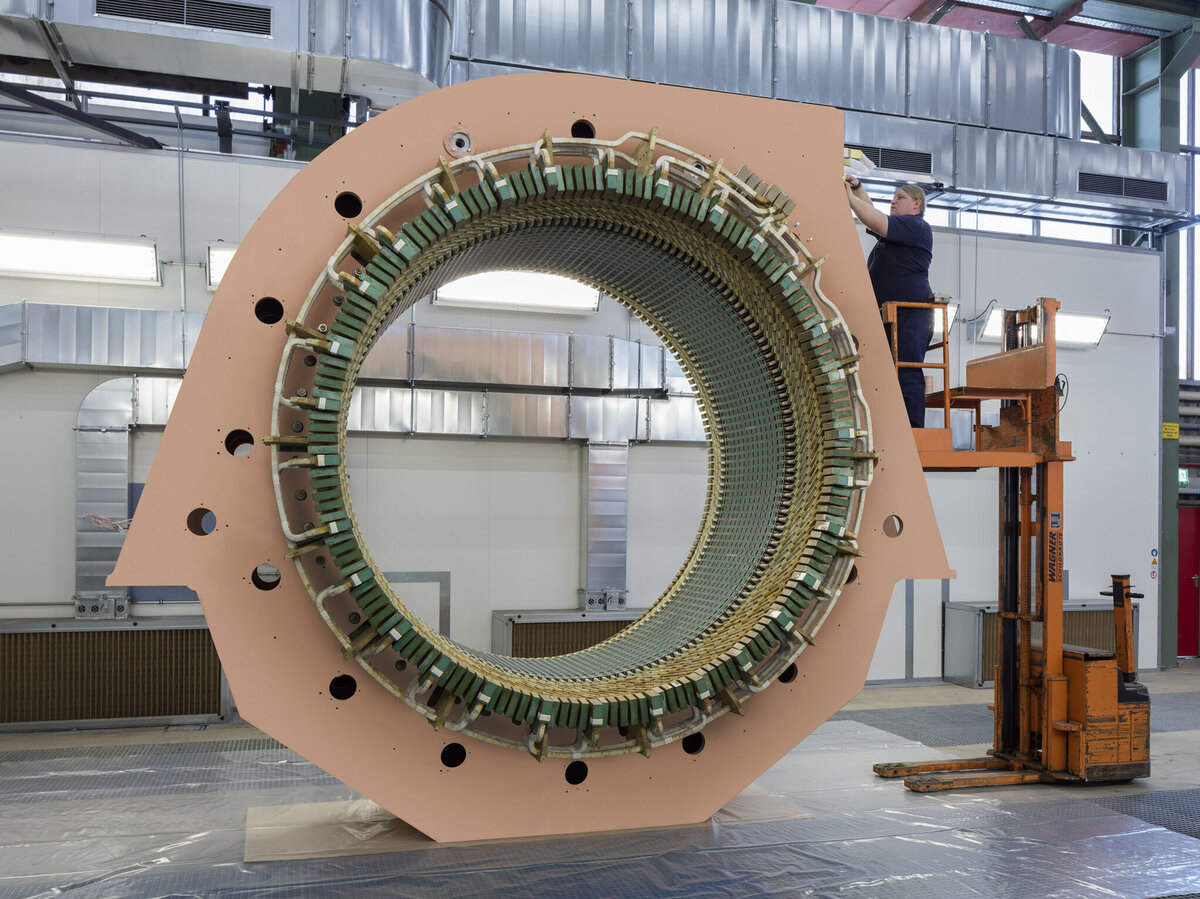

Regensburg, Karlsruhe – Electrical Machines

Locations: Regensburg (main location, production area 9000 m²), Karlsruhe, Leuna

Focus: Electrical machines

- Generators: Turbine generators, hydroelectric generators, single-phase generators

- Motors: High-voltage motors, low-voltage motors, DC machines

Service (for all performance classes) for:

- Low, medium, high, and direct current drives

- Explosion-proof drives

Service portfolio:

- Maintenance, repair, and servicing

- Spare parts manufacturing

- Engineering and modernization

- Diagnostics/analysis

- Rewinding of armatures and stators

- Damage analysis

Services for:

- Turbine generators

- Hydroelectric generators

- Engines

New production of:

- Coil windings

- Group insert windings

- Roebel bar windings

- Plug-in windings

Engineering and modernization:

- Redesign of the entire magnetic and electrical circuit

- Loss optimization through redesign

- Weak point analysis in case of damage

Bilfinger Rotating Equipment Germany GmbH - Essen

Econova-Allee 1

45356 Essen

Tel.: +49 941 910 30

Bilfinger Rotating Equipment Germany GmbH - Karlsruhe

Nördliche Raffineriestraße 1

76187 Karlsruhe

Tel.: +49 941 910 30

Bilfinger Rotating Equipment Germany GmbH - Leuna

In den Leunawerken Bau 3526

06237 Leuna

Tel.: +49 346 1432 727

Bilfinger Rotating Equipment Germany GmbH - Regensburg

Wiener Str. 19

93055 Regensburg

Tel.: +49 941 910 30

Get in Touch Now

Global Product Manager Mechanical

Management

CEO

Contact today

CEO

Contact today