- UPM Biochemicals’ innovative biorefinery uses unique process to produce biochemicals from sustainably sourced hardwood

- Bilfinger provides innovative, tailored full-service maintenance to enhance plant efficiency under a 6-year framework agreement

- First of its kind plant lays groundwork for production of consumer goods with reduced CO2 footprint

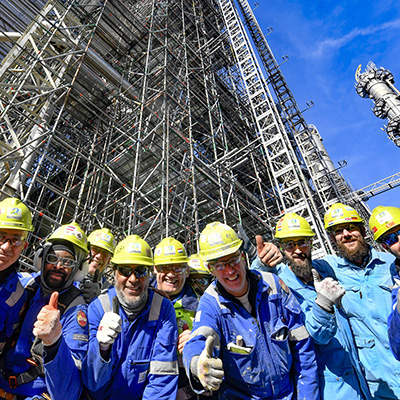

Leuna, Germany. Industrial services provider Bilfinger enters into a 6-year framework agreement with UPM Biochemicals covering comprehensive maintenance services for a new, sustainable production plant: At its Leuna site, UPM Biochemicals is currently building the world’s first biorefinery for the production of hardwood-based biochemicals. As their solution partner for the maintenance of all trades involved, Bilfinger will ensure the plant’s long-term efficient operation. The facility will produce approximately 220,000 tons of basic chemicals and thus provide more sustainable raw materials for further processing into a range of consumer applications.

The industrial-scale biorefinery, valued at 1.180 million euro, is a world first. It uses certified beech wood from sustainable forestry, particularly from the German region of Saxony-Anhalt and neighboring federal states. The raw biomass is harvested and used in the context of forestry in Central European beech forests, where biological diversity and natural ecosystems are preserved. Its origin is fully traceable and controlled and is subject to either the FSC® or the PEFC control system.

“With our biorefinery in Leuna, we are doing global pioneering work, allowing us to rethink chemical production,” says Michael Duetsch, Vice President of UPM Biochemicals. “Our plant is based on a unique process that places special demands on maintenance. With Bilfinger, we have a solution provider at our side who, thanks to their many years of experience, can provide precisely the support we need in all the necessary trades.”

Beech is considered a climate-resistant species with a tree population that will continue to grow in German forests in the coming decades. That is what makes it a future-proof raw material to UPM. The timber, which is usually sold as regular firewood, industrial wood and sawmill waste, is transported to Leuna through a regional logistics chain. Here, around 220,000 tons of biochemicals per year are produced from the biomass using hydrolysis, among others. The results are bio-monoethylene glycol (BioMEG) as base material for PET bottles, bio-monopropylene glycol (BioMPG) for the production of, for example, detergents, and renewable functional fillers (RFFs) as a sustainable alternative to carbon black and precipitated silica.

“UPM’s biorefinery plays a key role in the transformation of the chemicals value chain towards a circular economy,” says Thomas Schulz, Bilfinger Group CEO. “We are excited to be part of shaping the success of this transformation for greater sustainability. Our professional, comprehensive maintenance services will ensure efficient operations.”

Bilfinger will provide all maintenance services in one solution, from plant, mechanical and electrical components to measurement and control technology as well as analytical technology. UPM benefits from Bilfinger’s many years of experience, bundled and combined in the Bilfinger Maintenance Solution (BMS). On their journey to being the No. 1 for customers in enhancing efficiency and sustainability, Bilfinger has been a solution partner for pioneering approaches like UPM’s for years. Further examples are the biochemicals manufacturer Metsä Fibre and Circtec, whose unique technology converts used tires into biofuels.

![[Translate to English:]](/fileadmin/_processed_/f/2/csm_Andreas_Hilpert2_ddc1f2fbe5.jpg)

![[Translate to English:]](/fileadmin/_processed_/f/c/csm_400x400_Ulrich_Trebbe_V2_Website_ab0e20129e.png)