Battery production

Bilfinger is accelerating the future of electro mobility, helping the industry in minimizing the CO2 footprint. Our experienced team is delivering comprehensive solutions for raw material processing, battery components production, cells assembly plants, gigafactories and recycling facilities.

Having over 60 years of experience in the automotive business and a long-term track of chemical projects, Bilfinger has been awarded several contracts for over 37 million euro for projects related to e-mobility. All projects are innovative in terms of investors' know-how and the production process technology is being continuously developed. By that we can say that Bilfinger supports its customers on their path to a “state of the art” factory.

Raw materials processing

Raw materials mining and processing are the first steps in the battery production process. Bilfinger supports its customers across multiple areas, for example: extraction of manganese from the ground and subsequent processing into pure manganese sulfate monohydrate; several projects in lithium mining, where Bilfinger has experience with different innovative ways of lithium processing; and highly efficient processing plant of rare earth metals (REE) used in electric motors and wind turbines.

In addition, Bilfinger applies its knowledge from other metallurgy projects in Europe and beyond.

Added value:

- Interdisciplinary teams with well-trained workforce

- Expertise in geology and experience from metallurgy projects

- Bilfinger water management solutions

Components production

The wide range of products essential for producing battery cells includes not only cathode and anode materials and electrolyte—the production of which is a purely chemical industry play—but also copper foils, separators and others. Bilfinger has successfully executed multiple projects for all these components.

Added value:

- Experience from the chemical market

- Expertise in process engineering

Cells production & Gigafactories

Producing battery cells is the most discussed, expensive and technologically progressive part of the battery value chain. Announced and already executed investments, often called gigafactories, are usually large-scale projects requiring multiple suppliers. The result is a supply park with several companies in the same place or close to each other.

Bilfinger has supported several multibillion EUR gigafactory projects across Europe, delivering various parts of the factory and supporting customers with services including consulting, process integration, project localization, among others.

Added value:

- Several projects executed – in the engineering and execution phases

- Comprehensive multidisciplinary support

- Clean rooms and dry rooms experience

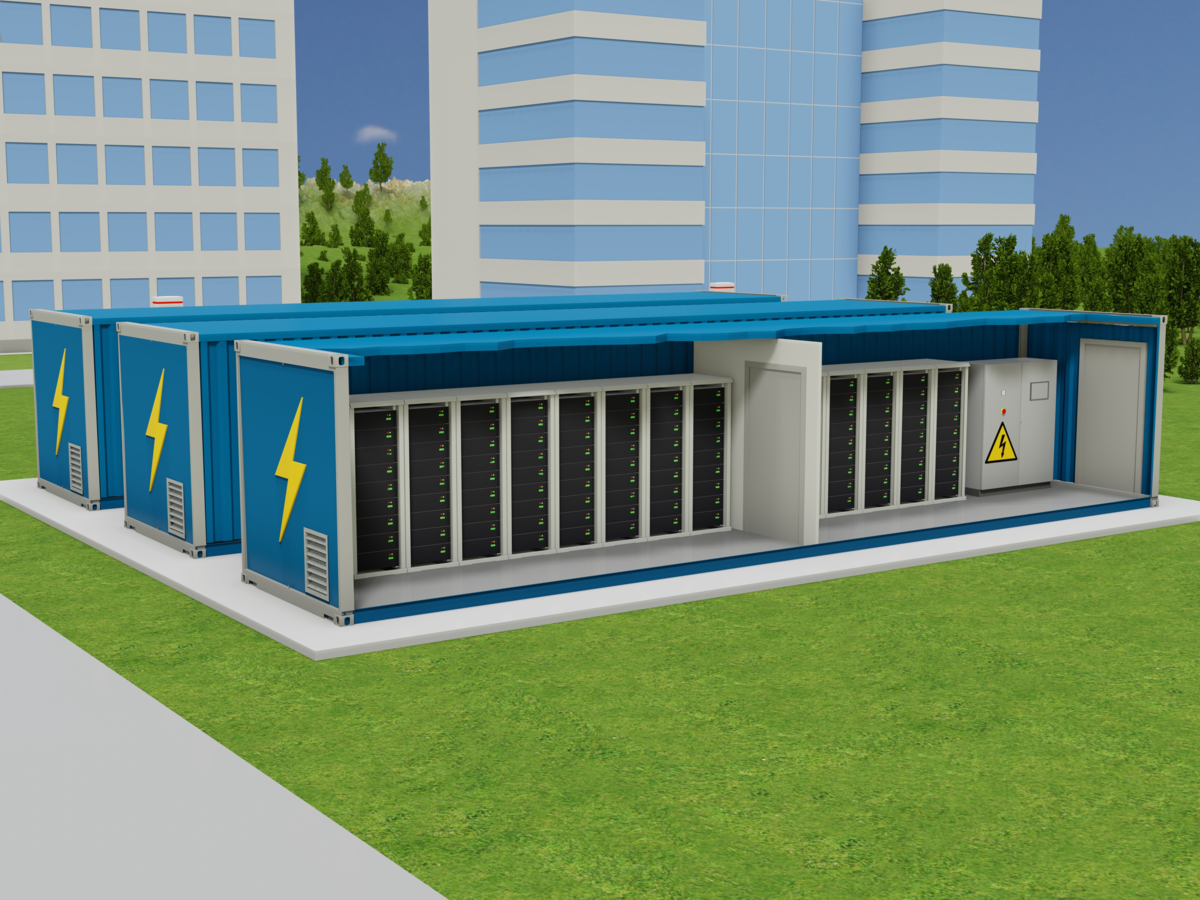

Battery assembly & BESS

As the world seeks new solutions for CO2 reduction, the effective utilization of energy from renewable sources and the balancing of high- and low-peak electricity consumption, battery-based energy storage systems offer immense potential. On top of that, when purposefully thought-out from the beginning, old batteries from EVs can be used, which means extending battery life through second use.

Residential and commercial buildings, industrial plants and municipalities are sectors making BESS an essential part of energy

Added value:

- Experience from BESS production plant

Battery recycling

After second-life use, there is no better way to close the battery production cycle than to recycle them. Many leading companies and experts are trying to find the best environmentally friendly and effective solution for direct recycling, where the maximum number of components are sent back into the production loop and used again. The global target is above 95% in recyclability of Li-ion batteries.

Besides direct recycling, current well-known recycling processes such as pyro-metallurgy and hydrometallurgy are used and are still being improved.

Added value:

- Chemical industry experience

- Experience from metallurgy projects

- Water management solutions

We make

climate-friendly mobility

work

What sets us apart:

- Bilfinger is familiar with the needs of its customers and has expertise in battery plant projects

- Multidisciplinary teams with highly-skilled employees

- Strong expertise in bridging international standards and local requirements

- Broad range of services and comprehensive solutions from a single source

- Strong consulting practice to support project preparation Workshops for modular prefabrication

Where our battery and e-mobility expertise make a difference

![[Translate to English:]](/fileadmin/_processed_/b/4/csm_Dag-Stroemme_6bdc2d4478.jpg)

Global Products & Innovation Director

![[Translate to English:]](/fileadmin/_processed_/b/4/csm_Dag-Stroemme_1b12d26d38.jpg)