Carbon Capture,

Utilization and Storage

Carbon Capture, Utilization and Storage (CCUS) is a key technology for achieving a Net Zero industry. We help companies capture, process and store CO2 emissions as they are generated, significantly reducing the amount of environmentally harmful greenhouse gas emissions.

Bilfinger has 20 years of experience working on the possibilities and processes for capturing, processing, transporting and storing CO2 emissions. We have implemented CCUS projects in industries ranging from energy supply, oil and gas, cement, chemicals and metallurgy to biogas.

With its know-how, Bilfinger develops and supports along the entire CCUS technology. This includes the capture and separation of CO2 emissions as well as their purification, compression and liquefaction through to their storage and transport. Bilfinger also supports its customers with a comprehensive portfolio of services for the use of captured CO2 emissions. Put your trust in Bilfinger and join us on the road to a Net Zero industry.

We have a track record and specific know-how in the field of waste incineration plants.

We successfully carry out projects in the oil, gas and energy industry.

At 100 €/t, the ROI of a CCUS plant drops to 10 years.

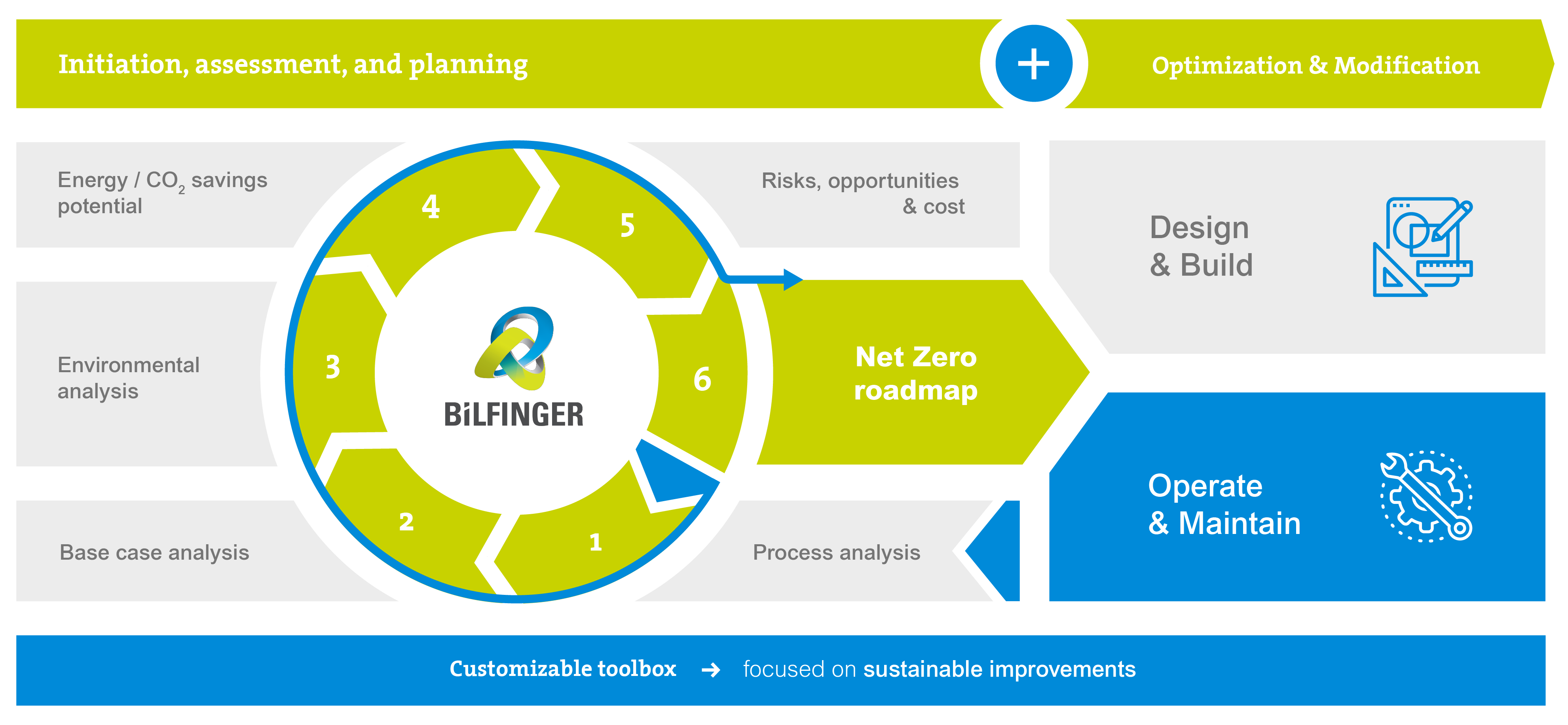

From Net Zero roadmap to implementation – a lifecycle approach

Industrial manufacturers around the world are intensively addressing the question of how to make net-zero operation of their plants possible. Our systematic approach provides our customers with one-stop solutions that support them on the path to a more sustainable future. We work closely with our partners to establish sustainability goals and deliver customized solutions that actively optimize energy use, integrate renewable energy sources and enhance operational processes.

With our comprehensive product portfolio, we bring these solutions to life and ensure their ongoing efficiency through operational and maintenance services. Bilfinger is the partner of choice for industry when it comes to driving sustainability and achieving net zero objectives.

Key Components of the Net Zero Approach

The Net Zero Approach is a comprehensive solution developed by Bilfinger to address the complex challenges associated with achieving net zero operations. It consists of three main phases:

We work closely with our customers to develop a customized roadmap outlining the steps needed to achieve Net Zero operations. This phase involves assessing current operations, setting sustainability goals and identifying key measures to be implemented. These measures are designed at feasibility level (+/- 40%) and prioritized in a timeline, resulting in the final output: the roadmap.

Once the roadmap has been established, our team of experts design tailored measures to address energy efficiency, renewable energy integration, and operational optimization. These measures are carefully crafted to align with our customers’ sustainability objectives and operational requirements.

The final phase involves the implementation of the identified measures, including construction, installation and ongoing maintenance. Our goal is to ensure seamless execution and long-term sustainability of the implemented solutions.

![[Translate to English:]](/fileadmin/_processed_/b/6/csm_Massimo-Pardocchi_1617c6bc3b.jpg)

President Business Line Energy Transition