Turnaround

Bilfinger Turnaround Solution

Standard procedure in the process industry is to close down plants on a regular basis so that they can be thoroughly checked and improved as part of a general plant shutdown, also known as turnaround. For industrial plant operators, this means:

- Production down time,

- Losing substantial turnover and profits, and subsequently

- Potentially causing reputational impact with customers and shareholders.

With its Bilfinger Turnaround Solution (BTS), Bilfinger has developed a methodology that enables plant turnarounds in the process industry to be implemented in an optimal way. The result is a systematic approach allowing turnarounds to be planned and executed at various locations of the respective customer, and over multiple turnaround cycles.

When plants stand still: We make your turnaround work

Process industry plants must undergo a turnaround every two to five years to ensure their integrity. During this process, production is stopped and comprehensive maintenance, inspection and modernization work is conducted. The quick completion of the turnaround is crucial when it comes to keeping these downtimes and the costs associated with them as short as possible.

Bilfinger is your experienced turnaround partner. We successfully carry out more than 80 major and many smaller turnarounds every year for our customers in Europe alone. Our knowledge and experience has been bundled in our Bilfinger Turnaround Solution (BTS). These solution allows us to respond individually to the requirements of our customers. We draw up a detailed project plan that includes all the necessary work steps and their timing. Not only are all services across the entire value chain documented, but efficient time management is also made possible. In addition, we make use of digital solutions, such as the turnaround app that we developed in-house.

Advantages for our customers:

- Reduced downtime, improved work planning and scheduling

- Longer intervals between turnarounds through the use of digital solutions, resulting in an increase in the service life of plant equipment

- Securing qualified personnel by accessing our global network of experienced turnaround specialists

- Ensuring safety and quality through implementation of the highest standards

- Providing cost-efficient and transparent solutions through attractive contract models and optimal turnaround execution

Benefits of a strategic turnaround partnership with Bilfinger

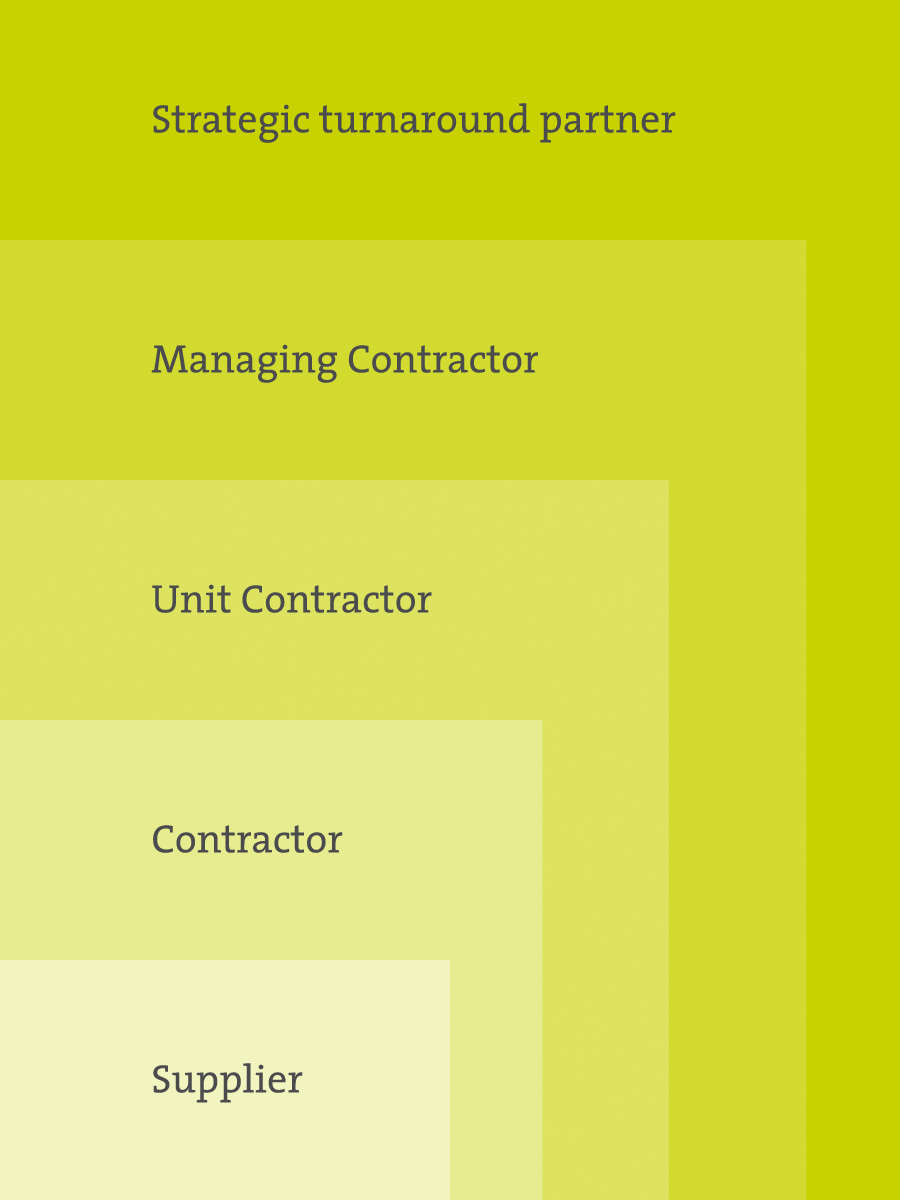

Bilfinger offers turnaround services at all collaborative levels, whether as supplier, managing contractor or as a strategic partner.

This said, a strategic partnership with Bilfinger is the option offering the most extensive benefits. The holistic approach on turnarounds focuses not only on the usual tasks and responsibilities of a managing contractor. We also ensure long-term continuous improvement, knowledge management and resource assurance.

Our customers can count on following benefits:

- Strict adherence to the same high HSE standards by all our employees

- Skilled personnel who deliver optimal quality and innovative solutions for complex problems

- Quick and flexible access to a wealth of resources and special tools

- Intelligent digital solutions for an efficient turnaround management

- Years of experience, compiled and made available for all projects in our BTS handbook

- Fewer interfaces thanks to having one major partner

- Customized collaboration models tailored to the customer's individual needs.

Where our turnaround services have made a difference

![[Translate to English:]](/fileadmin/_processed_/f/7/csm_400x400_Dennis_Lubsch_Website_14ed9fe292.jpg)

Global Product Manager Turnaround