Integrated Inspection Services

Integrated inspection services

by Bilfinger

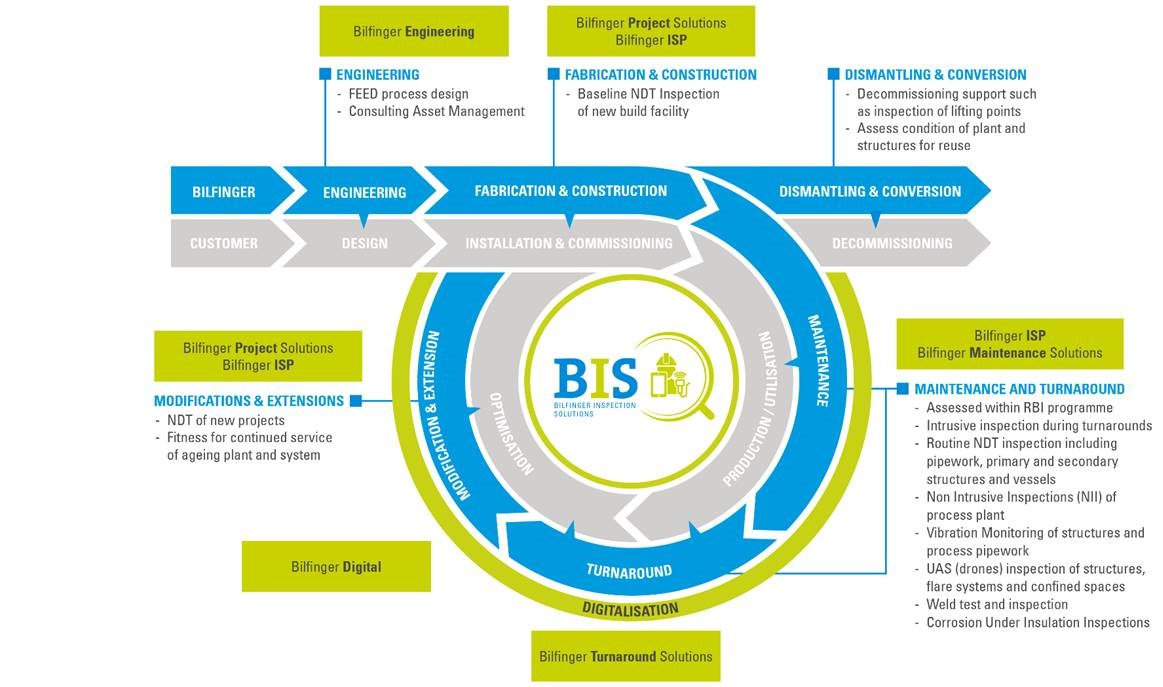

Our Bilfinger Inspection Solution (BIS) combines various inspection and supporting services into an efficient, single-interface solution for our customers.

Merging diverse inspections and support seamlessly, our highly-skilled specialists cater to all inspection needs throughout a plant's lifecycle, spanning fabrication, through routine in-service inspection, to decommissioning.

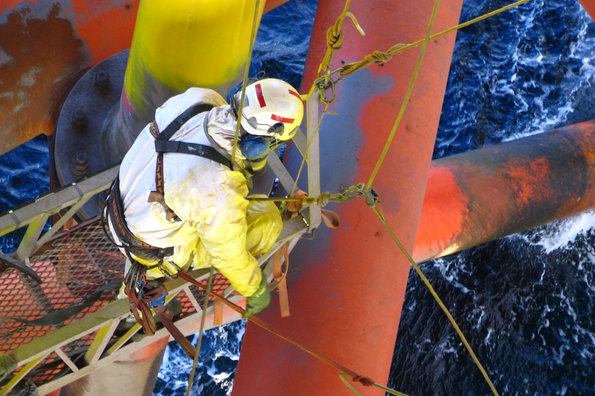

Our multi-skilled teams, many are also trained in industrial rope access, enable us to deliver productivity savings of as much as 30%, in comparison to traditional approaches.

are rope access trained

Adopting level 4 Bilfinger Inspection Solutions

with end to end service provision

For comprehensive industrial asset operation - encompassing safety, efficiency, and regulatory compliance throughout its lifecycle - our fully integrated inspection services will ensure your assets’ continued integrity while optimizing performance through consistent monitoring and inspection.

Why inspection services from Bilfinger?

- Fully integrated services along the entire inspection cycle lead to maximised productivity and cost efficiencies

- Fit-for-purpose, effective risk-based inspection and maintenance strategies ensure asset integrity along the entire lifecycle of a plant

- One single contact point

- Expert network that finds the right solution for every challenge

- Large pool of multi-disciplinary skilled workers with certificates for all relevant inspection activities

- Best-in-class safety

- Local access to Bilfinger’s world-class inspection expertise and technology

Bilfinger is an established provider of conventional, advanced and specialist non-destructive testing services and accredited to ISO/IEC 17020 and ISO/IEC 17025.

With our flexible contract setup, our customers just select the services they need:

- Initial assessment

Risk Based Inspection (RBI), planning and scheduling, inspection database management, regional inspection legislation

- Access solutions

Rope access, scaffolding, elevated platforms, drones/robotics

- Testing and inspection

Non-Destructive Testing (NDT) and Advanced Non-Destructive Testing (ANDT), Corrosion Under Inspection (CUI), Corrosion Inspection Program (CIP), Inspection of corrosion under pipe supports (CUPS), lab testing, structural health monitoring, asset condition surveys

- Integrity engineering

Engineering assessment, inspection plans, pressure systems, corrosion management, data analysis and improvement

- Material Technology

Material selection, material optimization, corrosion tests, portable analysis of microstructure, positive material identification (PMI), x-ray fluorescence (XRF), spectral analysis, process optimization, corrosion under insulation (CUI), corrosion in process (CIP) and risk based inspection (RBI)

- Failure Analysis

Corrosive failure analysis and corrosion tests, mechanical and technical failure analysis (scanning electron microscope, FEM analysis and integral product analysis, mechanical-technological testing – tensile, charpy, hardness, microstructure)

- Remedial

Fabric maintenance, fabrication and modification, repairs composite and temporary, insulation

- Engineering

Front End Engineering Design (FEED), asset management, Corrosion Under Inspection (CUI) expertise

- Vendor inspection

Verification of documents and processes, inspection during manufacturing, supply chain management

- Expediting

Field and desk expediting, quality audits, progress reporting

- Fabrication inspection

Non-Destructive Testing (NDT) and Advanced Non-Destructive Testing (ANDT), quality assurance and quality control, material handover supervision

With a variety of tools, we offer solutions to contain fugitive emissions, including reactive leak detection, proactive flange management programs, valve modifications, rotating equipment sealing and innovative tank solutions.

We are an established provider of Conventional, Advanced and Specialist Non-Destructive Testing (NDT) ISO/IEC 17025 and ISO/IEC 17020 services:

- Acoustic Emission Testing

- Boroscope/fibroscope

- Dye penetrant testing

- Eddy current testing

- Ferrite testing

- Magnetic particle testing

- Ultrasonic flaw detection and thickness measurement

- Portable hardness testing

- Positive material identification

- Radiographic testing

- Thermography

- Ultrasonic testing

- Visual inspection

- Computed radiography

- CUI – Corrosion under Insulation

- Digital radiography

- Multi-skip ultrasonic

- Phased array

- Pulsed eddy current

- Real time radiography

- Structural health monitoring

- Time of flight diffraction

- Ultrasonic corrosion mapping

- Ultrasonic flaw detection and thickness measurement

- Verkade Inspection Method for pipe supports

Our highly skilled teams work for you all over the world, onshore and offshore. It doesn t matter where your industrial plant is located - we offer our integrated inspection services exactly where they are needed. Bilfinger entities for inspections are located in UK, Denmark, the Netherlands, Austria, Germany and the United States.

![[Translate to English:]](/fileadmin/_processed_/1/a/csm_David_Hall_eedfff2f84.png)