- Comprehensive range of services for multi-year corrosion prevention project

- Integrated inspection concept delivers testing, access solutions, corrosion protection and insulation from a single source

- Pre-inspections conducted in record time: significant time and cost savings

- Growth in strategic business area of inspection services continues after recent inspection contract wins in Denmark and the UK

Bilfinger is undertaking inspection work and enhancing energy efficiency by insulating plant components at one of the largest chemicals plants in Europe. The project is scheduled to run over a number of years with the objective of inspecting all relevant parts of the plant for corrosion under insulation (CUI). Bilfinger’s experts will replace the insulation according to the latest standards wherever necessary and thus not only enhance the integrity and availability but also the energy efficiency of the plant. Based on its integrated inspection concept, which includes testing procedures, access solutions, corrosion protection and insulation all from a single source, the industrial services provider has already successfully conducted the first pre-inspections in record time.

“We are proud to support our customer with the implementation of this extensive CUI-project,” says Christina Johansson, interim CEO and CFO at Bilfinger. “Heat loss not only leads to unnecessary energy costs, but also to higher emissions. With its extensive expertise, our team is able to identify and implement the measures to enhance the energy and cost efficiency at the plant.”

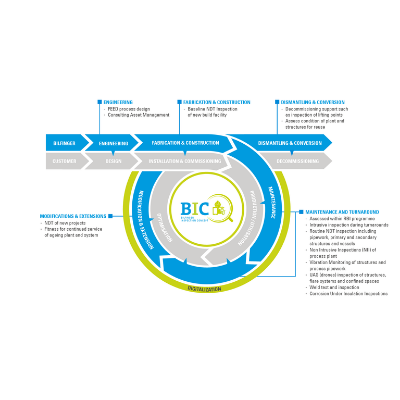

Corrosion under insulation is a particular challenge because it generally goes unnoticed until extensive damage has already occurred. To prevent this from happening, Bilfinger provides insulation, access solutions, corrosion protection and maintenance services on various assets at the plant. Inspections are also required in advance of the work so that potential corrosion damage can be identified beforehand. With the integrated Bilfinger Inspection Concept (BIC), the industrial services provider is bundling its inspections expertise and can thus deliver the entire inspection process from a single source.

Bilfinger has already conducted pre-inspections of some parts of the chemical plant that are difficult to access. Normally, elaborate scaffolding would have been required, but an innovative combination of rope access technicians and non-destructive testing (NDT) experts turned out to be highly time- and cost-efficient: the pre-inspection was completed in three months instead of the six months initially expected.

With this contract, Bilfinger continues on its growth path in the business area of inspection services: Recently, the industrial services provider has been awarded a €40 million inspection contract by Total. The five-year contract covers inspection services on all offshore assets of Total E&P Denmark (Exploration & Production), with focus on advanced non-destructive testing (ANDT) techniques. In March 2021, Bilfinger furthermore extended its existing service delivery with Altera Infrastructure with a multi-million pound inspection contract: For the next three years, Bilfinger will continue to provide a range of conventional and advanced non-destructive testing (ANDT) services on assets operated by Altera in the UK.

The Bilfinger Inspection Concept (BIC) offers Bilfinger customers a holistic inspection process from a single source, minimizing coordination efforts, time and costs. BIC is flexibly scalable and covers the entire inspection cycle of process industry plants: from pre-inspections and test procedures to the actual inspection and reporting to modernization and performance enhancement. The range of services integrates all Bilfinger Group services, including risk-based inspection (RBI), rope access techniques, scaffolding, drone operations, NDT, acoustic emission testing as well as digital analysis and reporting tools. ISO 17020 and ISO 17025 accreditations and the deployment of proven experts ensure the highest quality and safety standards.